Eaton-Battery-Handbook-BAT11LTA.PDF

Full-float operation – Operation of a DC system with the battery, battery charger and load connected in parallel, with the battery charger supplying the normal DC load plus any self

Get Price

Uninterruptible Power Supply (UPS) Backup Battery

Battery Cabinets Arimon designs and manufactures custom uninterruptible power supply (UPS) backup battery cabinets, battery racks and accessories for the

Get Price

How to measure output current of battery | Information by

Breaker/fuse is sized to load and so is cable (overcurrent protects cable). Size the source to equal or exceed the combined loads. See it all works together. The feeder between

Get Price

Eaton 93PM UPS 100-500 kVA User s and installation guide

The battery converter derives its input from the regulated DC output of the rectifier and provides regulated charge current to the battery. The battery is always connected to the UPS and ready

Get Price

ESS-GRID Cabinet Brochure EN-241028

The ESS-GRID Cabinet series are outdoor battery cabinets for small-scale commercial and industrial energy storage, with four diferent capacity options based on diferent cell

Get Price

Liebert® EXS External Battery Cabinet Installer/User Guide

For battery cabinets that are connecting to a VertivTM Liebert® EXS UPS, see Figure 2.1 on page 8, cables will run from the positive, negative and neutral busbars of the adjacent battery

Get Price

Microsoft Word

DataSafe® HX Front Terminal Battery Cabinets are shipped partially assembled, internally pre-wired and come standard with a circuit breaker for over current protection. Each cabinet is

Get Price

Battery & Power Supply Testing!

The current you see displayed is the nominal charging current being output to the battery (it should appear as a "negative" number if you''ve connected everything properly).

Get Price

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the

Get Price

UBC87 Battery Cabinet Installation, Operation,

Install the main POS and NEG cables from the output circuit breaker to the correct battery posts on the designated battery units shown in the provided battery system schematic.

Get Price

UNDERSTANDING BATTERY INPUT OUTPUT A

Battery charging cabinets are a type of safety cabinet that''s designed especially for lithium-ion batteries. Over the recent years, as the prevalence of lithium-ion batteries has grown in

Get Price

Guidelines for Current Transformer (CT) installation

Use cases for CT installation The CT measurements provide valuable system information to the installers and homeowners about PV production, home consumption, and IQ Battery

Get Price

Battery Cabinets & Enclosures

Exponential Power''s Battery Cabinets & Enclosures provide durable, secure solutions for telecommunications and industrial applications. Designed to protect battery systems, these

Get Price

Battery & Power Supply Testing!

The current you see displayed is the nominal charging current being output to the battery (it should appear as a "negative" number if you''ve connected

Get Price

How to test the internal current of the battery cabinet

The Hioki BT3562 battery tester is designed to measure internal resistance using an AC current at a measurement frequency of 1 kHz, letting you accurately capture the internal resistance of

Get Price

Battery Cabinets for Uninterrupted Power Supply (UPS)

Battery Cabinets Through cutting-edge research and innovation, advanced engineered power products for backup battery cabinets have become

Get Price

Battery Cabinet

For a UPS system that does not ground the DC/Battery Circuit, isolation should be maintained between the chassis and any point in the battery circuit, to reduce the risk of electric shock

Get Price

How to Check Battery Amps with a Multimeter

Learn how to check battery amps with a multimeter. A step-by-step guide to ensure accurate readings and battery health.

Get Price

ATC Cabinets | Paradigm Traffic Systems

Cabinets One of the most critical components of a signalized intersection is the traffic control cabinet. The Econolite controller cabinet houses the signal

Get Price

Battery Cabinet Cost Structure and Optimiza-tion

Chapter 2 describes how UPS devices and battery cabinets work and what their applications can be. Chapter 3 deals with the DFMA method which was used when analyzing the current

Get Price

Eaton 93PM Integrated Battery Cabinet-Large and Large

The battery cabinet contains its own energy source. The internal wiring and output terminals may carry live voltage even when the UPS is not connected to an AC source.

Get Price

Eaton Samsung Gen 3 Battery Cabinet Installation and

Control wiring can be routed through the sides of the battery cabinets in side by side configurations or through the top of the battery cabinets using conduit in standalone

Get Price

Acrel Hall Current Sensor in Battery Cabinet Monitoring

When the battery is charged and discharged, there are strict requirements on the charge and discharge current. This paper introduces the realization of the battery charge and

Get Price

BC55 Battery Cabinet Installation, Operation, & Maintenance

The option provides functional access to the equipment circuit breaker via a handle located on the exterior of a cabinet door that is physically connected to the circuit breaker in the cabinet''s

Get Price

How To Measure Current Of Battery Using Multimeter? A Simple

Measuring the current of a battery using a multimeter is a fundamental skill for anyone working with electronics. This process involves carefully connecting the multimeter in

Get Price

Samsung Gen 2 lithium battery cabinet site plan

SOURCE 1 (REQUIRED) SHALL BE PROVIDED FROM THE UPS OUTPUT DISTRIBUTION; SOURCE 2 (OPTIONAL) SHALL BE PROVIDED FROM THE UPS BYPASS INPUT. FOR

Get Price

6 FAQs about [How to view the output current of the battery cabinet]

Can a battery cabinet be connected to a DC Circuit?

The battery cabinet frame is not referenced to the DC circuit. Each battery cabinet has its own overcurrent protection device. Internal battery strings are to be connected by an authorized Eaton Customer Service Engineer. 1.7 For More Information for UPS cabinet conduit and terminal specifications and locations.

How do you test a battery?

Read the voltage level of the battery with a digital multimeter or hydrometer-style battery tester. Measure the current flow with the multimeter. Disconnect the multimeter and turn off the electrical system of the device. Reconnect the negative terminal of the battery.

Where is the battery cabinet located?

The battery cabinet may be located to either the right or left of the UPS cabinet. The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21.

Where do I install a line-up and match Battery Cabinet?

Line-up-and-match battery cabinets are installed adjacent to the UPS. The recommended installation location is on the right side of the UPS cabinet as viewed from the front of the cabinet. See Figure 3 for line-up-and-match configuration views. Figure 3. Eaton 93PM 100 kW UPS and Two 93PM Integrated Battery Cabinets

How to check battery amps using a multimeter?

To check the amps of your battery using a multimeter, you need to execute an amp measurement test. This test involves connecting the multimeter in series with the power source and measuring the current flow. Here are the steps to follow: Step 1: Turn off the electrical system of your vehicle or device to avoid any damage to the circuit.

Where is the UPS battery cabinet located?

The recommended location is to the right of the UPS cabinet. This procedure assumes the battery cabinet is located to the right of the UPS cabinet. 21. If line-up-and-match installation, remove the rectangular knockout on the bottom front side of the UPS and the IBC (see Figure 15).

More related information

-

How to use weak current backup battery cabinet with ESS power base station

How to use weak current backup battery cabinet with ESS power base station

-

How much current and voltage does the battery cabinet have

How much current and voltage does the battery cabinet have

-

How much power does the battery cabinet output

How much power does the battery cabinet output

-

The battery output current of the energy storage cabinet is large

The battery output current of the energy storage cabinet is large

-

Does the communication high voltage battery cabinet have current and how to connect it

Does the communication high voltage battery cabinet have current and how to connect it

-

How to increase the current of the battery cabinet

How to increase the current of the battery cabinet

-

How to calculate the battery cabinet current

How to calculate the battery cabinet current

-

How big a site should I buy a battery cabinet for

How big a site should I buy a battery cabinet for

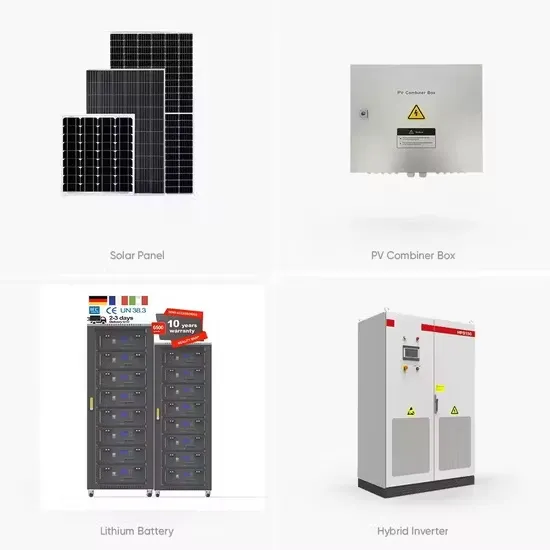

Commercial & Industrial Solar Storage Market Growth

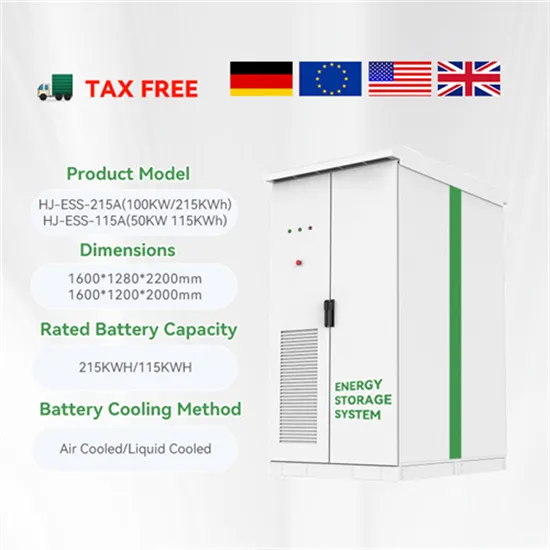

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

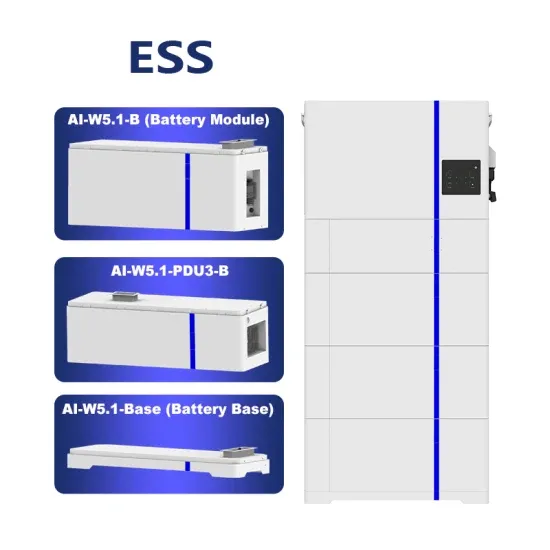

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.