Review on operation control of cold thermal energy storage in

The integration of cold energy storage in cooling system is an effective approach to improve the system reliability and performance. This review provides an overview and recent

Get Price

What is energy storage temperature control? | NenPower

Effective temperature control in energy storage systems is paramount for ensuring optimal performance and safety. Management of temperature not only influences operating

Get Price

How to achieve energy storage temperature control

The implementation of energy storage system (ESS) technology with an appropriate control system can enhance the resilience and economic performance of power systems.

Get Price

Advanced Temperature Control Applied on An Industrial Box

Typically, a box furnace is designed to perform a particular thermodynamic process under an open-loop control system. The profile of the fuel energy power is the model input

Get Price

The Ultimate Guide to Energy Storage Temperature Control Box:

If you''re managing solar farms, EV charging stations, or even just a home battery system, you''ve probably faced this headache: batteries that underperform in extreme heat or

Get Price

Temperature controlled warehouses

A temperature controlled warehouse is a logistics facility that houses goods in a specific environment. These warehouses can incorporate any storage system, but AS/RS are

Get Price

What Is a Control Box? Functions, Types & Uses

Discover what a control box is, how it works, key components, types, and design tips for industrial, commercial, and residential use.

Get Price

What are the functions of energy storage temperature control system

The significance of energy storage temperature control systems is multifaceted and reaches beyond simple temperature regulation. These systems serve primarily to maintain

Get Price

The Importance of Thermal Management in Energy

By collecting temperature data and controlling heating, cooling, and other equipment according to a certain logic, the temperature control

Get Price

Numerical study on temperature control of double-layer phase

The formula for this combined economic and cold retention performance evaluation index is as follows: (6) a = t Costs where t represents the cooling time when the temperature

Get Price

Integrated cooling system with multiple operating modes for

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

Temperature Controlled Energy Storage: The Secret Sauce for

Temperature controlled energy storage is like giving those batteries a 5-star spa treatment, ensuring they perform optimally without breaking a sweat. Let''s dive into why this tech is

Get Price

Testing Energy Storage High-Voltage Boxes for Safety

Explore essential testing procedures for energy storage high-voltage boxes—from visual checks and CAN communication to insulation and temperature rise testing for safe battery systems.

Get Price

Cooling storage with a resorption process. Application to a box

It is obviously interesting to control accurately the cooling temperature in order to maintain the air of the box at the good temperature. For the process using an evaporator

Get Price

Design of structure and control system of semiconductor refrigeration box

In order to create low temperature environment for the valve testing, a new type of semiconductor refrigeration box based on semiconductor refrigeration chip and programmable

Get Price

What is energy storage temperature control? | NenPower

Effective temperature control in energy storage systems is paramount for ensuring optimal performance and safety. Management of

Get Price

The Importance of Thermal Management in Energy Storage Systems

By collecting temperature data and controlling heating, cooling, and other equipment according to a certain logic, the temperature control system is able to adjust the

Get Price

Commercial Refrigeration Temperature & Defrost Control

Commercial Refrigeration Temperature & Defrost Control and Optimization Joe Dudley Regional Sales Manager KE2 Therm Solutions, Inc.

Get Price

CT-Energy Storage Air-Cooled Temperature Control Unit

The Energy Storage Air-Cooled Temperature Control Unit is used to regulate the temperature of energy storage systems in applications such as renewable energy storage, data centers,

Get Price

PLC-Based Tank Temperature Control Using PID Algorithm

The PLC-based temperature control system can regulate temperatures in reactors, distillation columns, and storage tanks, enhancing process efficiency and safety.

Get Price

Temperature-Controlled Warehouses: Effective Guide

Temperature-controlled warehouses have evolved as crucial components for protecting the quality and integrity of diverse products, ranging

Get Price

Smart design and control of thermal energy storage in low-temperature

On the utilization side, low-temperature heating (LTH) and high-temperature cooling (HTC) systems have grown popular because of their excellent performance in terms of energy

Get Price

TEMPERATURE CONTROL: THE CRUCIAL THERMAL

Temperature control measures play a crucial role in mitigating the risk of thermal runaway by closely monitoring and regulating the internal temperature of the system. Every

Get Price

Principle of energy storage box temperature control system

High Energy Density: TCES systems offer greater energy storage density than sensible and latent heat systems, allowing for more compact storage solutions. No Thermal Losses: Energy is

Get Price

Understanding Energy Management for Energy

The importance of energy management in energy storage systems & the role of BMS, BESS Controller, & EMS in optimizing performance &

Get Price

What are the functions of energy storage temperature

The significance of energy storage temperature control systems is multifaceted and reaches beyond simple temperature regulation. These

Get Price

Integrated cooling system with multiple operating modes for temperature

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

The Importance of Thermal Management in Energy

It is responsible for monitoring battery voltage, current, temperature, and other operating parameters, and adapting thermal

Get Price

CT-Energy Storage Air-Cooled Temperature Control Unit

The Energy Storage Air-Cooled Temperature Control Unit is used to regulate the temperature of energy storage systems in applications such as renewable

Get Price

6 FAQs about [The function of the energy storage box temperature control system]

How much energy does a container storage temperature control system use?

The average daily energy consumption of the conventional air conditioning is 20.8 % in battery charging and discharging mode and 58.4 % in standby mode. The proposed container energy storage temperature control system has an average daily energy consumption of 30.1 % in battery charging and discharging mode and 39.8 % in standby mode. Fig. 10.

Do cooling and heating conditions affect energy storage temperature control systems?

An energy storage temperature control system is proposed. The effect of different cooling and heating conditions on the proposed system was investigated. An experimental rig was constructed and the results were compared to a conventional temperature control system.

How much energy does a temperature control system use?

The average energy consumption of the proposed temperature control system accounts for about 3.5 % of the energy storage, in which the average energy consumption of charging mode and discharge mode accounts for 1.06 %, and the energy consumption of standby mode accounts for 1.41 %. Fig. 7.

What is the operation mode of energy storage battery?

When the energy storage battery operates in charging/discharging mode, the operation mode is VCRM for the proposed temperature control system when the outdoor temperature is greater than 20 °C. And the operation mode is switched to VPHPM when the outdoor temperature is greater than or equal to 20 °C.

Do temperature control systems save energy?

The energy consumption of the two temperature control system prototypes under the mode of twice charging and twice discharging per day and the analysis of the energy saving potential in typical cities applications are investigated. The main conclusions of this study are as follows:

What is the COP of a container energy storage temperature control system?

It is found that the COP of the proposed temperature control system reaches 3.3. With the decrease of outdoor temperature, the COP of the proposed container energy storage temperature control system gradually increases, and the COP difference with conventional air conditioning gradually increases.

More related information

-

Uruguay energy storage temperature control price

Uruguay energy storage temperature control price

-

The function of energy storage power station control cabinet

The function of energy storage power station control cabinet

-

Brazilian energy storage temperature control system manufacturer

Brazilian energy storage temperature control system manufacturer

-

The function of containerized battery energy storage box

The function of containerized battery energy storage box

-

Burundi energy storage temperature control system equipment

Burundi energy storage temperature control system equipment

-

Dominican energy storage temperature control system manufacturer

Dominican energy storage temperature control system manufacturer

-

Container Energy Storage Battery Temperature Control

Container Energy Storage Battery Temperature Control

-

Energy storage temperature control 60kw liquid cooling

Energy storage temperature control 60kw liquid cooling

Commercial & Industrial Solar Storage Market Growth

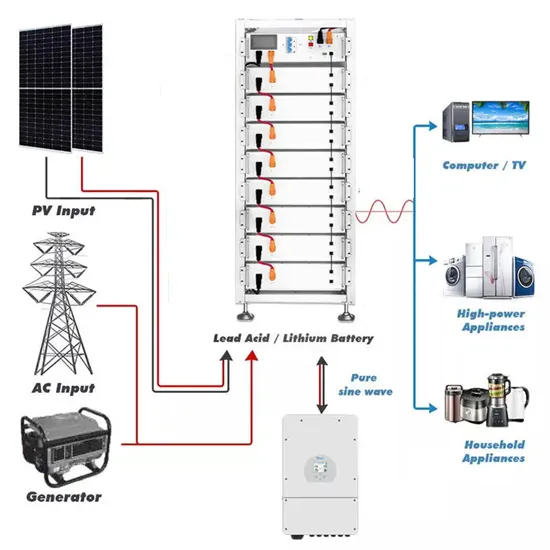

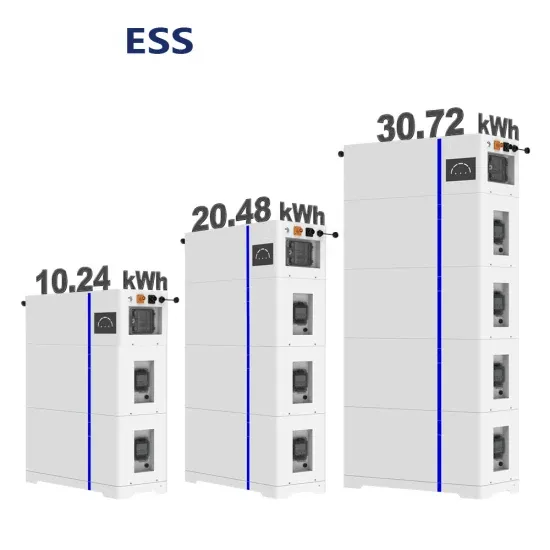

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.