LIQUID COOLING SOLUTIONS For Battery Energy Storage

LIQUID COOLING SOLUTIONS For Battery Energy Storage Systems or operating networks and systems for the Energy industry? If so, consider building t Thermal management is vital to

Get Price

Review on operation control of cold thermal energy storage in cooling

The integration of cold energy storage in cooling system is an effective approach to improve the system reliability and performance. This review provides an overview and recent

Get Price

Liquid Cooling Chiller(Commercial Energy Storage)

Battery Energy Storage Systems are filled with many battery cells, generating a large amount of extreme heat load. This means that the cooling system needs

Get Price

110KW/215KWh Liquid-Cooling Energy Storage Integrated

In order to ensure the safety of energy storage power stations, the selection and design of energy storage system equipment should follow the principles of "prevention first, prevention and

Get Price

60kW 1000V DC Power Supply Liquid Cooling

Designed for harsh environments, the 60KW liquid cooling module from the professional EV charger module supplier operates reliably under extreme

Get Price

40kW 60kW Liquid Cooling Power Module for DC EV Charger

ADVANCED TECHNOLOGY The 30kW Power Module is isolated design, supporting hot plug, with output reverse irrigation isolation, to ensure personal safety and the safety of the EV

Get Price

Cooler Buildings, Stronger Grid: A New Approach to Air

2) The Energy Storage tanks hold the separated fluids for later use. 3) The Conditioner dries and cools the air by using the stored concentrated liquid desiccant and

Get Price

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Get Price

ESIE Energy Storage Summit: Energy storage safety,

A temperature control product developed for applications such as battery cooling in the energy storage industry, suitable for high-power energy storage scenarios, to control the

Get Price

liquid cooling energy storage system

Liquid cooling energy storage technology, with its superior performance in thermal management, safety, and space utilization, is becoming an indispensable part

Get Price

60kW 1500V liquid-cooled dc fast charging module for

The MXR150060BL Liquid-Cooled Power Module utilizes third-generation silicon carbide (SiC) semiconductors as its core components, offering zero noise,

Get Price

Chiller Module

Our Liquid Cooling System represent a state-of-the-art solution that provides reliable, efficient, and cost-effective thermal management to enhance the performance, safety, and longevity of

Get Price

liquid cooling energy storage system

Liquid cooling energy storage technology, with its superior performance in thermal management, safety, and space utilization, is becoming an indispensable part of modern energy systems.

Get Price

CATL 0.5P EnerOne+ Outdoor Liquid Cooling Rack

BMS is used in energy storage system, which can monitor the battery voltage, current, temperature, managing energy absorption and release, thermal

Get Price

Optimized thermal management of a battery energy-storage

The strategies of temperature control for BTMS include active cooling with air cooling, liquid cooling and thermoelectric cooling; passive cooling with a phase-change

Get Price

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get Price

How Liquid Cooling is Transforming Battery Energy

With increasing regulatory requirements and the push for sustainability, liquid cooling is rapidly becoming the preferred solution for battery energy storage

Get Price

A review of battery thermal management systems using liquid cooling

Pollution-free electric vehicles (EVs) are a reliable option to reduce carbon emissions and dependence on fossil fuels. The lithium-ion battery has strict requirements for

Get Price

Liquid Cooling Bess Battery Storage

30% higher energy density than air cooling system, decrease installation area Smart liquid cooling temperature control system, decrease 20% auxiliary

Get Price

60kW Liquid-Cooled Containerized Air Conditioner for Energy Storage

Through advanced sensing technology and control systems, temperature accuracy of ±0.5°C and humidity control of ±3% RH can be achieved, ensuring optimal operating conditions for data

Get Price

60kW 1000V DC Power Supply Liquid Cooling Rectifier Module

Designed for harsh environments, the 60KW liquid cooling module from the professional EV charger module supplier operates reliably under extreme temperatures, high humidity, and

Get Price

Chillers for Renewable Energy Storage Case Study

Chiller for Renewable Applications Challenge While Boyd has decades of experience designing custom cooling systems for high heat loads and precise

Get Price

60kw Liquid-Cooled Energy Storage Air Conditioner High

This solution significantly reduces power consumption in large-scale deployments while maintaining precise control over temperature and humidity (± 0.5° C / ± 5% RH).

Get Price

The first large-scale grid side independent energy storage power

The project adopts the Envicool BattCool energy storage 60kW large cooling capacity liquid cooling unit, which has an ultra wide temperature operating range, meets

Get Price

60kW Liquid-Cooled Containerized Air Conditioner for Energy

Through advanced sensing technology and control systems, temperature accuracy of ±0.5°C and humidity control of ±3% RH can be achieved, ensuring optimal operating conditions for data

Get Price

5 FAQs about [Energy storage temperature control 60kw liquid cooling]

What are the different types of liquid cooling units?

However, each integrator’s thermal design varies, particularly in the choice of liquid cooling units, which come in different cooling capacities: 45kW, 50kW, and 60kW. Despite using the same 314Ah battery cells, why do these systems differ so significantly in liquid cooling unit selection? Let’s delve into the details.

Why is a 5MWh Bess cooling system important?

Continuous innovation and in-depth exploration are necessary to optimize and perfect these systems, ultimately creating high-performance products with core competitive advantages. In conclusion, designing an efficient cooling system for 5MWh BESS containers is essential to ensure optimal performance, safety, and longevity of the battery cells.

How does a liquid cooling system work?

The design of liquid cooling units aims to ensure that, starting at an initial temperature of 25°C, the batteries can undergo two cycles of charge and discharge at a 0.5C rate. After a four-hour charge-discharge cycle, the system rests for one hour before undergoing a second four-hour cycle.

What temperature should battery cells be kept in a cooling unit?

The cooling unit must ensure the maximum temperature of the battery cells within the container does not exceed the threshold set by the battery manufacturer (such as 45°C or 50°C) at the end of these cycles. Operating battery cells above 35°C accelerates aging, resulting in faster degradation.

What is the cooling load of a battery?

Here, the cooling load depends on the difference between the maximum operating temperature of the battery (such as 35°C, 40°C, 45°C, 50°C) and the initial temperature of 25°C (∆T).

More related information

-

Energy storage liquid cooling temperature control product brand

Energy storage liquid cooling temperature control product brand

-

Energy Storage Liquid Cooling Temperature Control Solution

Energy Storage Liquid Cooling Temperature Control Solution

-

Five liquid cooling control modes for energy storage

Five liquid cooling control modes for energy storage

-

Liquid cooling system energy storage price

Liquid cooling system energy storage price

-

Energy storage battery liquid cooling equipment manufacturer

Energy storage battery liquid cooling equipment manufacturer

-

Liquid cooling standard energy storage cabinet configuration

Liquid cooling standard energy storage cabinet configuration

-

Eritrea Huijue liquid cooling energy storage cabinet price

Eritrea Huijue liquid cooling energy storage cabinet price

-

Nepal Energy Storage Battery Liquid Cooling Solution

Nepal Energy Storage Battery Liquid Cooling Solution

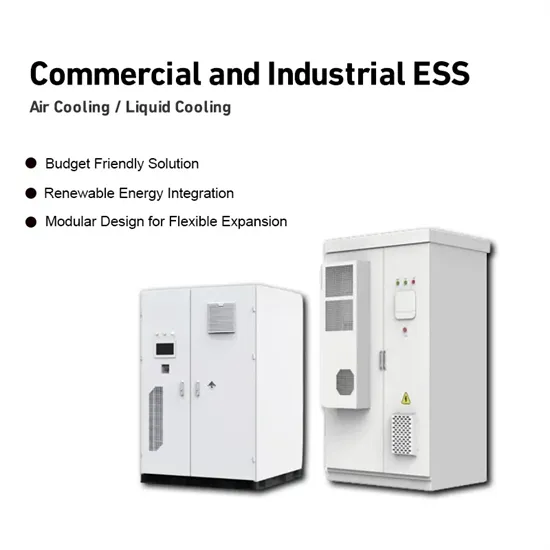

Commercial & Industrial Solar Storage Market Growth

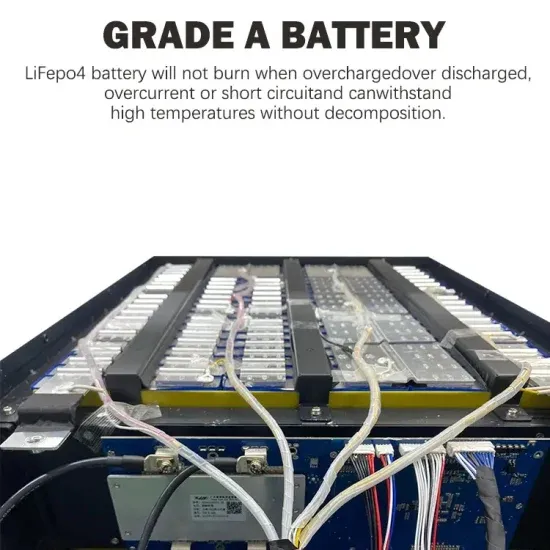

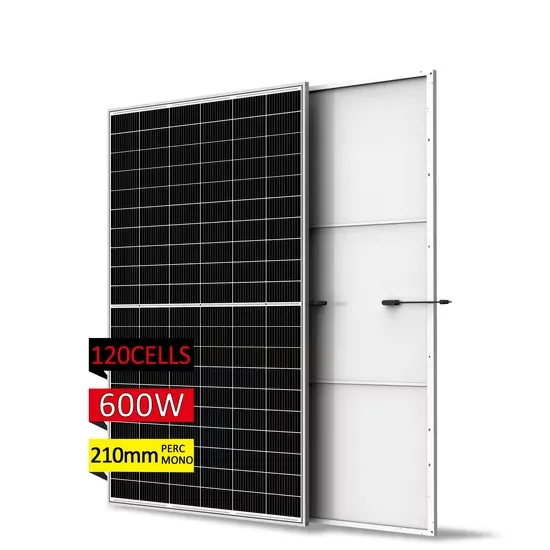

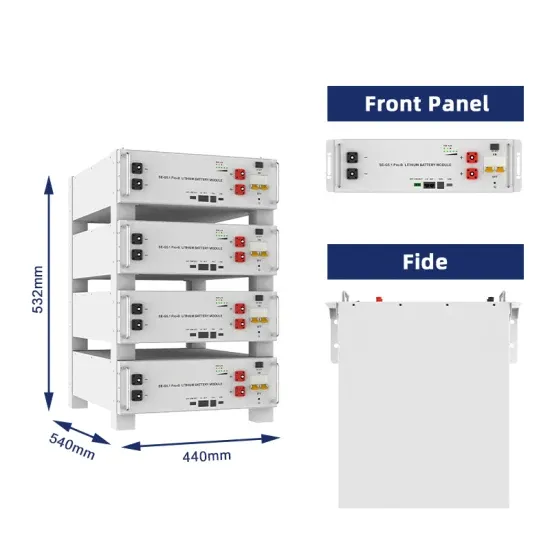

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.