Liquid Cooling for BESS

The DMC 8.0 is a high-performance, door-mounted liquid chiller designed for compact battery energy storage systems and other demanding applications. With advanced features and

Get Price

EMW series liquid cooling unit for energy storage

Battcool-C series air cooled chiller for energy storage container is mainly developed for container battery cooling in the energy storage industry. It is

Get Price

Liquid Cooling Energy Storage: The Next Frontier in Energy

Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Get Price

What does energy storage liquid cooling mean? | NenPower

Energy storage liquid cooling refers to a method of temperature regulation in energy storage systems. This process entails the use of liquid mediums to absorb, transfer,

Get Price

Liquid Cooling Energy Storage Systems: Scaling Up for a

Let''s face it – when you think about energy storage, "temperature control" probably doesn''t make your top 5 buzzwords. But here''s the shocker: liquid cooling technology is quietly

Get Price

Stationary Battery Energy Storage Market Growth Driven by Liquid

These solutions are critical for high-power applications such as grid stabilization, renewable energy storage, and uninterruptible power supplies, positioning the liquid cooling

Get Price

Evolution of Thermal Energy Storage for Cooling Applications

Thermal energy storage (TES) for cooling can be traced to ancient Greece and Rome where snow was transported from distant mountains to cool drinks and for bathing water for the wealthy. It

Get Price

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

1. Short heat dissipation path, precise temperature control Liquid-cooled systems utilize a CDU (cooling distribution unit) to directly introduce low-temperature coolant into the

Get Price

Efficient Cooling System Design for 5MWh BESS Containers:

Discover the critical role of efficient cooling system design in 5MWh Battery Energy Storage System (BESS) containers. Learn how different liquid cooling unit selections impact

Get Price

Liquid Cooling Energy Storage Systems | All-in-One BESS Cabinet Solutions

Ranging from 208kWh to 418kWh, each BESS cabinet features liquid cooling for precise temperature control, integrated fire protection, modular BMS architecture, and long-lifespan

Get Price

Liquid-cooling becomes preferred BESS temperature control option

For every new 5-MWh lithium-iron phosphate (LFP) energy storage container on the market, one thing is certain: a liquid cooling system will be used for temperature control.

Get Price

CT-Energy Storage Temperature Control Full Liquid

This product is suitable for PACK & PCS full liquid cooling solutions. While ensuring heat dissipation for the PACK, it also provides liquid cooling for the

Get Price

InnoChill''s Liquid Cooling Solution: Revolutionizing

Discover how InnoChill''s liquid cooling solution is transforming energy storage systems with superior heat dissipation, improved battery life,

Get Price

Integrated cooling system with multiple operating modes for temperature

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

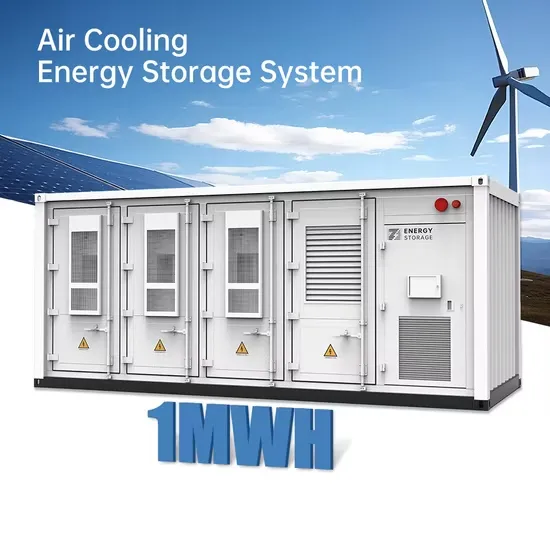

EXPLORING THE ADVANTAGES OF AIR-COOLED

Introduction: Battery Energy Storage Systems (BESS) play a crucial role in modern energy management, providing a reliable solution for

Get Price

Cabinet Air Conditioner for Battery Energy Storage

Applications Our Battery Energy Storage System (BESS) Liquid & Air Cooling Solutions are designed for a wide range of applications, ensuring stable

Get Price

CT-Energy Storage Temperature Control Full Liquid Cooling Solution

This product is suitable for PACK & PCS full liquid cooling solutions. While ensuring heat dissipation for the PACK, it also provides liquid cooling for the PCS. This improves the heat

Get Price

Liquid-cooling becomes preferred BESS temperature

For every new 5-MWh lithium-iron phosphate (LFP) energy storage container on the market, one thing is certain: a liquid cooling system will be

Get Price

Liquid Cooling Energy Storage: The Next Frontier in Energy Storage

Liquid-cooled energy storage is becoming the new standard for large-scale deployment, combining precision temperature control with robust safety. As costs continue to

Get Price

InnoChill''s Liquid Cooling Solution: Revolutionizing Energy Storage

Discover how InnoChill''s liquid cooling solution is transforming energy storage systems with superior heat dissipation, improved battery life, and eco-friendly cooling fluids.

Get Price

Integrated cooling system with multiple operating modes for

The proposed energy storage container temperature control system provides new insights into energy saving and emission reduction in the field of energy storage.

Get Price

What does energy storage liquid cooling mean?

Energy storage liquid cooling refers to a method of temperature regulation in energy storage systems. This process entails the use of liquid

Get Price

Industrial And Commercial Energy Storage-Temperature Control

Air cooling and liquid cooling have been applied on a large scale, and technologies under development include heat pipe cooling and phase change cooling.<br/> Mainstream

Get Price

Liquid Cooling in Energy Storage: Innovative Power Solutions

Liquid cooling addresses this challenge by efficiently managing the temperature of energy storage containers, ensuring optimal operation and longevity. By maintaining a

Get Price

Liquid-cooled energy storage drives demand for

At present, there are three main types of companies involved in energy storage temperature control, namely data center temperature control

Get Price

Liquid Cooling Energy Storage Systems | All-in-One

Ranging from 208kWh to 418kWh, each BESS cabinet features liquid cooling for precise temperature control, integrated fire protection, modular BMS

Get Price

Thermal management solutions for battery energy storage systems

Listen this articleStopPauseResume This article explores how implementing battery energy storage systems (BESS) has revolutionised worldwide electricity generation and

Get Price

Liquid-Cooled Energy Storage, An Efficient Cooling Technology

1. Energy storage field: Liquid cooling solution becomes the mainstream trend Temperature affects the capacity, safety, life and other performance of electrochemical energy

Get Price

How Can Liquid Cooling Revolutionize Battery Energy

Among these, Battery Energy Storage Systems (BESS) are particularly benefiting from this innovative approach to cooling. As the demand for more efficient

Get Price

Liquid-cooled energy storage drives demand for temperature

At present, there are three main types of companies involved in energy storage temperature control, namely data center temperature control companies, industrial cooling

Get Price

Battery Energy Storage Systems Cooling for a sustainable

a sustainable future Solutions Systems The Pfann nberg Battery Cooling Solutions maintain battery packs at an optimum average temperature. They are suitable for ambient temperatures

Get Price

Multi-objective topology optimization design of liquid-based cooling

Among these solutions, liquid-based cooling has attracted wider attention because of its excellent heat capacity and flexible control. The primary task of BTMS is to effectively

Get Price

6 FAQs about [Energy Storage Liquid Cooling Temperature Control Solution]

What is a composite cooling system for energy storage containers?

Fig. 1 (a) shows the schematic diagram of the proposed composite cooling system for energy storage containers. The liquid cooling system conveys the low temperature coolant to the cold plate of the battery through the water pump to absorb the heat of the energy storage battery during the charging/discharging process.

What is container energy storage temperature control system?

The proposed container energy storage temperature control system integrates the vapor compression refrigeration cycle, the vapor pump heat pipe cycle and the low condensing temperature heat pump cycle, adopts variable frequency, variable volume and variable pressure ratio compressor, and the system is simple and reliable in mode switching.

Do cooling and heating conditions affect energy storage temperature control systems?

An energy storage temperature control system is proposed. The effect of different cooling and heating conditions on the proposed system was investigated. An experimental rig was constructed and the results were compared to a conventional temperature control system.

What is the COP of a container energy storage temperature control system?

It is found that the COP of the proposed temperature control system reaches 3.3. With the decrease of outdoor temperature, the COP of the proposed container energy storage temperature control system gradually increases, and the COP difference with conventional air conditioning gradually increases.

Is vapor compression refrigeration technology a promising energy-saving solution?

Therefore, the integration of vapor compression refrigeration technology, vapor pump heat pipe technology and heat pump technology for temperature control of energy storage containers is a promising energy-saving solution.

What is the energy saving rate of composite temperature control system?

In Hohhot, the ACCOP of conventional air-cooled air conditioning is 4.1, while the proposed composite temperature control system reaches 5.1, and the energy saving rate is close to 25 %. Even if the proposed composite temperature control system is adopted in Guangzhou, the energy saving rate is still more than 5 %. Fig. 5.

More related information

-

Energy storage temperature control 60kw liquid cooling

Energy storage temperature control 60kw liquid cooling

-

Energy storage liquid cooling temperature control product brand

Energy storage liquid cooling temperature control product brand

-

Mexican Energy Storage Container Liquid Cooling System Solution

Mexican Energy Storage Container Liquid Cooling System Solution

-

Nepal Energy Storage Battery Liquid Cooling Solution

Nepal Energy Storage Battery Liquid Cooling Solution

-

Energy storage cabinet liquid cooling system control panel

Energy storage cabinet liquid cooling system control panel

-

Five liquid cooling control modes for energy storage

Five liquid cooling control modes for energy storage

-

Burundi energy storage temperature control system equipment

Burundi energy storage temperature control system equipment

-

Huawei Liquid Cooling Energy Storage

Huawei Liquid Cooling Energy Storage

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.