BU-808: How to Prolong Lithium-based Batteries

Battery packs do not die suddenly, but the runtime gradually shortens as the capacity fades. Lower charge voltages prolong battery life and electric vehicles and satellites

Get Price

The reason for lithium battery capacity loss and Why

If you look at your electronics, you''ll notice that the lithium-ion batteries they come with lose capacity over time. Once the theoretical cycle

Get Price

Do lithium-ion batteries just lose capacity over time or do they

The primary aging effect in a Lithium-ion battery is increased internal resistance (caused by oxidation of the plates). This doesn''t affect the Ah capacity, but it does reduce

Get Price

Capacity charging/discharging issue, only getting half. EG4-LL

If you have your battery or inverter set to 20-80% to get the 7000 cycles, it will eventually start to leak 10,20,30% and destroy your battery --- you''ll be running your battery

Get Price

Lithium battery pack voltage is halved

The article discusses the importance of understanding lithium ion battery voltage charts for solar system owners. It explains the basics of lithium ion batteries, their advantages, and their

Get Price

Half life of lithium batteries

When the battery is charging, positively-charged lithium ions move from one electrode, called the cathode, to the other, known as the anode, through an electrolyte solution in the battery cell.

Get Price

A critical review of battery cell balancing techniques, optimal

Electric Vehicles (EVs) release no tailpipe emissions, making them a cleaner and more environment friendly alternative to common internal combustion engine (ICE) vehicles.

Get Price

Li-ion / LiPo Battery Storage and Permanent Capacity Loss

Li-ion / LiPo should be stored approximately "half full" (40% – 50% of full charge) which does not mean half the battery voltage, but rather half of the battery''s charge capacity.

Get Price

Only getting 50% of battery capacity

A battery voltage of 12.2 volts for a lithium battery is not 50%, the Epever SOC is setup for lead acid and makes a poor guess based on voltage.

Get Price

The Fundamentals of Battery/Module Pack Test

The Importance of Battery Module and Pack Testing The battery market is growing rapidly due to the acceleration of electrification in the automotive, aerospace and energy industries. In turn,

Get Price

Lithium-Ion Battery Decline and Reasons For It

A lithium-ion battery holding 50% of its charge performs optimally. While a full battery charge accelerates wear through increased chemical

Get Price

Capacity evaluation and degradation analysis of lithium-ion battery

• A capacity calculating method specialized for electric vehicles is proposed. • The degradation models of battery capacity with mileage and time are established. • The influences

Get Price

Understanding Ah Ratings of Lithium Batteries

How Do Ah Ratings Define Lithium Battery Capacity and Runtime? The Amp Hour (Ah) rating quantifies the total electric charge a

Get Price

Comparison of Open Datasets for Lithium-ion Battery

This story is contributed by Abolfazl Shahrooei. Testing of Li-ion batteries is costly and time-consuming, so publicly available battery datasets

Get Price

Cell Capacity and Pack Size

Obviously Cell Capacity and Pack Size are linked. The total energy content in a battery pack in it''s simplest terms is: Energy (Wh) = S x P x Ah x

Get Price

A comprehensive guide to battery cathode and anode

When designing custom lithium battery pack, it is very important to correctly calculate the reasonable ratio of cathode and anode electrode

Get Price

Li-ion / LiPo Battery Storage and Permanent Capacity

Li-ion / LiPo should be stored approximately "half full" (40% – 50% of full charge) which does not mean half the battery voltage, but rather half of

Get Price

Can You Mix Different Capacity Lithium Batteries?

Yes, you can mix different capacity lithium batteries, whether a normal 12V 100Ah battery or a Lithium server rack battery. You can combine

Get Price

Capacity charging/discharging issue, only getting half. EG4-LL Lithium

If you have your battery or inverter set to 20-80% to get the 7000 cycles, it will eventually start to leak 10,20,30% and destroy your battery --- you''ll be running your battery

Get Price

Best rechargeable batteries in 2025, tried and tested

We tested 13 popular rechargeable batteries to compare their affordability, performance and reliability. Three emerged as the absolute best for most users.

Get Price

The reason for lithium battery capacity loss and Why there is

If you look at your electronics, you''ll notice that the lithium-ion batteries they come with lose capacity over time. Once the theoretical cycle number is exceeded, the capacity of

Get Price

Capacity evaluation and degradation analysis of lithium-ion

• A capacity calculating method specialized for electric vehicles is proposed. • The degradation models of battery capacity with mileage and time are established. • The influences

Get Price

The Science Behind Lithium Battery Capacity Loss

Lithium battery capacity fades mainly due to internal changes like SEI layer growth, lithium plating, and electrode wear, which reduce the battery''s ability to hold charge.

Get Price

A simple analysis of the causes of capacity loss in

Overcharging can cause a decrease in battery capacity, mainly due to the following factors: ① Overcharging reaction of graphite negative

Get Price

Lithium Ion (Li-Ion) Battery Packs

Lithium-ion cells whose equivalent lithium content exceeds 1.5 grams or 8 grams per battery pack must be shipped as "Class 9 miscellaneous hazardous material." Cell

Get Price

Understanding the limitations of lithium ion batteries at high rates

Charging lithium ion cells at high rates and/or low temperatures can be detrimental to both electrodes. At the graphite anode, there is a risk of lithium plating rather than

Get Price

A simple analysis of the causes of capacity loss in lithium

Overcharging can cause a decrease in battery capacity, mainly due to the following factors: ① Overcharging reaction of graphite negative electrode; ② Positive

Get Price

Cell Capacity and Pack Size

Obviously Cell Capacity and Pack Size are linked. The total energy content in a battery pack in it''s simplest terms is: Energy (Wh) = S x P x Ah x Vnom. Hence the simple

Get Price

Lithium-ion Battery Packs

Inventus Power offers advanced, globally certified lithium-ion battery solutions like the PROformance and U1LiFe Series, emphasizing safety, innovation, and reliability across

Get Price

6 FAQs about [Lithium battery pack capacity is halved]

Why is lithium battery capacity loss important?

Once the theoretical cycle number is exceeded, the capacity of the battery will have a very significant decline, and this time it is time to replace the battery. Therefore, lithium battery capacity loss is very important, especially the irreversible battery capacity loss, which is related to the battery life.

How much charge should a lithium ion / LiPo battery have?

Li-ion / LiPo should be stored approximately “half full” (40% – 50% of full charge) which does not mean half the battery voltage, but rather half of the battery’s charge capacity. Li-ion / LiPo batteries function via a chemical reaction that occurs inside their sealed enclosure.

When should you replace a lithium ion battery?

If you look at your electronics, you'll notice that the lithium-ion batteries they come with lose capacity over time. Once the theoretical cycle number is exceeded, the capacity of the battery will have a very significant decline, and this time it is time to replace the battery.

How long does a lithium ion battery last?

For example, a lithium-ion cell charged to 4.20V/cell typically delivers 300–500 cycles. If charged to only 4.10V/cell, the life can be prolonged to 600–1,000 cycles; 4.0V/cell should deliver 1,200–2,000 and 3.90V/cell should provide 2,400–4,000 cycles. On the negative side, a lower peak charge voltage reduces the capacity the battery stores.

What is a lithium battery?

Lithium batteries (or hybrid LIC capacitors) are different from other chemistries. These are highly sensitive to voltage and should always be above their required minimum discharge voltage but also below their maximum charge voltage required by the battery.

Why does a lithium ion battery lose power?

Since voltage also drops as the battery discharges, the increased resistance causes it to reach cutoff voltage earlier and so reduces its effective capacity. An old lithium-ion battery which is not powerful enough to run the device it was designed for may still be useful in a lower current application.

More related information

-

Lithium battery pack voltage and capacity

Lithium battery pack voltage and capacity

-

Capacity of lithium battery pack

Capacity of lithium battery pack

-

Ultra-large capacity 16 8v lithium battery pack

Ultra-large capacity 16 8v lithium battery pack

-

Large capacity lithium battery pack all

Large capacity lithium battery pack all

-

Poor capacity of lithium battery pack

Poor capacity of lithium battery pack

-

Large capacity lithium battery pack wholesale

Large capacity lithium battery pack wholesale

-

High capacity lithium battery pack customization

High capacity lithium battery pack customization

-

Niue large capacity lithium battery pack

Niue large capacity lithium battery pack

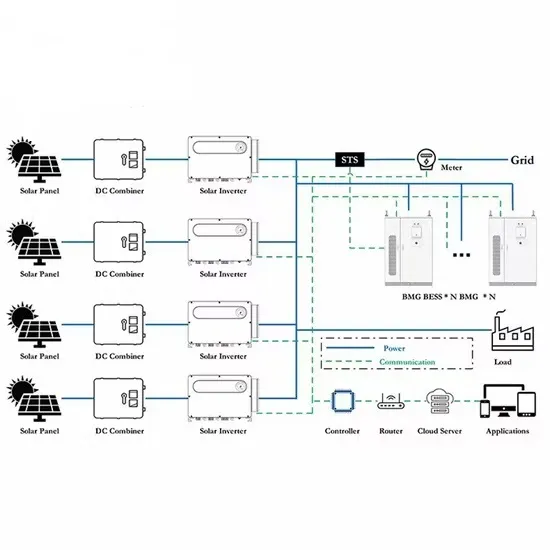

Commercial & Industrial Solar Storage Market Growth

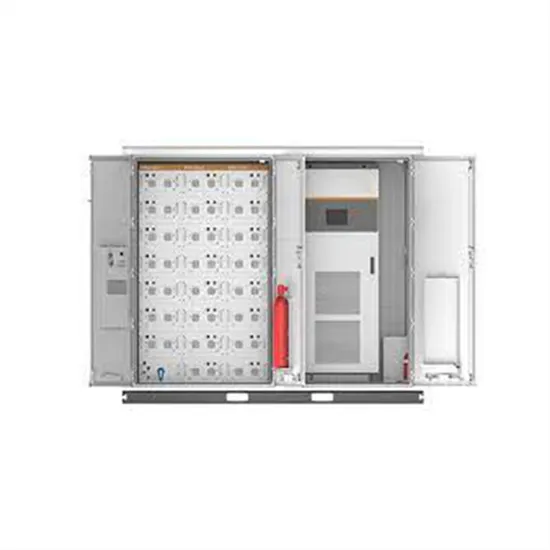

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.