Heat Dissipation in Solar Inverters

One of the key challenges in maintaining the efficiency and longevity of inverters is managing heat dissipation effectively. During operation, inverters generate heat due to energy

Get Price

Eight major differences between air cooling and liquid cooling in

Air cooling and liquid cooling are two commonly used heat dissipation methods in energy storage systems. When choosing a heat dissipation method, factors such as the actual power of the

Get Price

Case study on flywheel energy storage systems: LPTN-based

This study established a lumped parameter thermal network model for vertical flywheel energy storage systems, considering three critical gaps in conventional thermal

Get Price

How Does Thermal Grease Enhance Heat

By improving heat dissipation efficiency, ensuring equipment stability, reducing energy consumption, and lowering maintenance costs,

Get Price

How Solar Inverters Efficiently Manage High-Temperature

High temperatures can reduce solar inverter efficiency, limit power output, and shorten lifespan. Learn how heat impacts inverter performance and discover expert tips for

Get Price

How to Innovate Solar Inverter Heat Management?

Another hurdle in solar inverter heat management is the balance between cooling effectiveness and energy consumption. Active cooling systems, while often more efficient at

Get Price

How to dissipate heat effectively for photovoltaic inverters

primary tasks of an inverter heat dissipation system are to: select appropriate heat dissipation and cooling methods, design an effective cooling system, control the temperature of electronic

Get Price

HEAT DISSIPATION OF PHOTOVOLTAIC INVERTERS

A liquid-cooled heat dissipation energy storage device At the heart of a liquid cooling energy storage system is a carefully designed cooling loop. The coolant, typically a specialized fluid

Get Price

HEAT DISSIPATION DESIGN OF SOLAR INVERTERS

How long can solar thermal storage panels store heat Solar thermal energy storage is used in many applications, from building to concentrating solar power plants and industry.

Get Price

IGBT Energy Losses Analysis and Heat Dissipation System

This article mainly is to design the PCS to the storage system which is the three level topology inverter based on IGBT. And the paper proposes a design method of the heat dissipation

Get Price

Residential Energy Storage Inverter

Low Voltage Three Phase Hybrid Inverter S6-EH3P (8-15)K02-NV-YD-L Three phase low voltage energy storage inverter / 10 seconds of 200% overload capability / Multiple inverters can

Get Price

Heat Dissipation Methods of Solar Inverter

It is generally used for high-power inverters. Through the comparison experiment of the heat dissipation capacity of string inverters, it is found that the heat dissipation effect of

Get Price

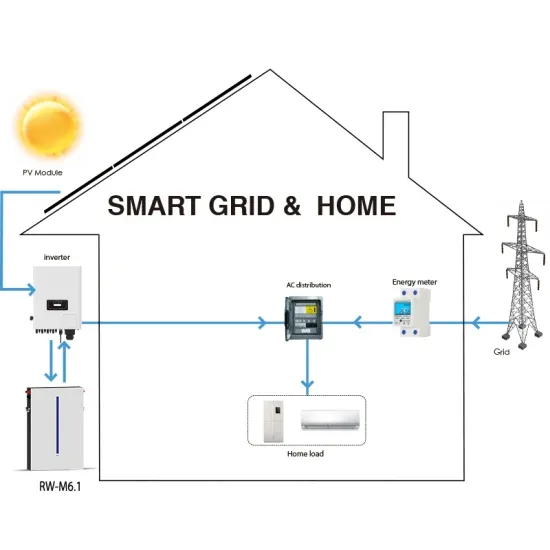

How Do Photovoltaic Inverters Work In Energy Storage Systems?

The application prospects for photovoltaic inverters in energy storage systems are very broad. With the rapid development and popularization of renewable energy, energy storage systems

Get Price

Photovoltaic inverter heat dissipation requirements

Efficient heat dissipation: The heat dissipation design should ensure that the heat generated by the inverter during operation can be dissipated in time and effectively, and keep

Get Price

WO/2024/245129 HEAT DISSIPATION ASSEMBLY, INVERTER, AND ENERGY STORAGE

A heat dissipation assembly, an inverter, and an energy storage power supply, relating to the fields of inverters and energy storage power supplies.

Get Price

Latest Developments in Solar Inverter Heat Dissipation

The integration of energy storage systems with solar inverters adds another layer of complexity to heat dissipation. As hybrid inverters become more prevalent, managing the

Get Price

Photovoltaic inverter heat dissipation requirements

Efficient heat dissipation: The heat dissipation design should ensure that the heat generated by the inverter during operation can be

Get Price

Synthetical Thermal Modeling and Optimization Design for High

Demanding accuracy and reliability of thermal design for high efficiency and high-power density inverter devices. Integrating heat conduction, convection heat transfer and fluid dynamics

Get Price

Analysis of the heat generation of the photovoltaic inverter shell

The following will do some analysis and answers for these two problems combined with inverter heat dissipation. The components in the inverter have their rated operating

Get Price

How Does Thermal Grease Enhance Heat Management in Energy Storage

By improving heat dissipation efficiency, ensuring equipment stability, reducing energy consumption, and lowering maintenance costs, thermal grease helps inverters operate

Get Price

Energy Storage Inverters Decoded: How HERIC Circuits Are

The Silent Energy Drain in Renewable Systems Ever wondered why even top-tier solar setups sometimes feel like they''re leaking power? Well, here''s the thing: conventional inverters in

Get Price

What are the heat dissipation measures for solar inverters?

The heat dissipation design of solar inverters directly affects their efficiency, lifespan, and stability, especially in high-power operation or high-temperature environments,

Get Price

Thermal Design of Photovoltaic Power Generation Inverter

The heat sources in inverter circuit include the DC/DC and DC/AC modules, which generates the amounts of heat at work. On the basis of PSIM, the thermal calculation models with heat

Get Price

Heat Dissipation Methods of Solar Inverter

At present, there are two main heat dissipation methods for solar inverters, including free cooling and forced air cooling.

Get Price

Sofar Solar HYD 4000-ES | SolarTraders

Single-Phase Energy storage integrated inverter with fanless self-recognition heat dissipation design, Flexible configuration of lead acid or lithium battery, Compatible with on grid off grid

Get Price

6 FAQs about [Energy storage inverter heat dissipation]

How does heat affect solar inverters?

One of the most significant ways heat affects solar inverters is through efficiency reduction. Inverters follow a temperature derating curve, meaning their efficiency decreases as temperatures rise. This phenomenon occurs because electronic components experience increased internal resistance at elevated temperatures, leading to:

How does an inverter prevent overheating?

To protect internal components from excessive heat damage, inverters incorporate automatic temperature derating mechanisms. As the temperature rises beyond safe operating limits, the inverter reduces its power output to prevent overheating. This can lead to: - Lower electricity generation during peak sunlight hours.

How do new-generation solar inverters work?

New-generation solar inverters come with innovative cooling solutions that help manage heat more effectively. These include: - Forced-Air Cooling: High-performance inverters use multiple fans to enhance airflow and rapidly dissipate heat.

What is a high performance inverter?

These include: - Forced-Air Cooling: High-performance inverters use multiple fans to enhance airflow and rapidly dissipate heat. - Liquid Cooling Systems: Some advanced models utilize liquid-cooled heat sinks for superior thermal management.

How to install a solar inverter?

Install them under eaves, awnings, or purpose-built shelters to minimize heat exposure. - Ensure adequate airflow and ventilation: Inverters should be mounted with sufficient clearance around them to allow proper heat dissipation. A minimum spacing of 30 cm on all sides is recommended.

How long do solar inverters last?

Most solar inverters are designed to last 10-15 years, but extreme heat can shorten this lifespan significantly. Frequent thermal stress causes: - Expansion and contraction of internal circuits, leading to micro-cracks. - Increased risk of overheating and shutdowns. - Higher maintenance and replacement costs. 1.

More related information

-

Energy storage lithium battery pack heat dissipation

Energy storage lithium battery pack heat dissipation

-

Heat dissipation of energy storage devices

Heat dissipation of energy storage devices

-

Liquid-cooled energy storage battery cabinet heat dissipation

Liquid-cooled energy storage battery cabinet heat dissipation

-

What are the container energy storage and heat dissipation technologies

What are the container energy storage and heat dissipation technologies

-

Flywheel energy storage motor heat dissipation

Flywheel energy storage motor heat dissipation

-

Energy storage battery compartment heat dissipation

Energy storage battery compartment heat dissipation

-

Heat dissipation of energy storage batteries

Heat dissipation of energy storage batteries

-

Energy storage battery cabinet heat dissipation

Energy storage battery cabinet heat dissipation

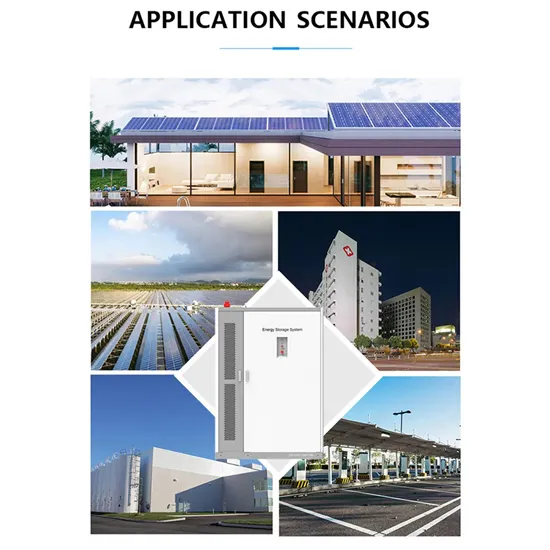

Commercial & Industrial Solar Storage Market Growth

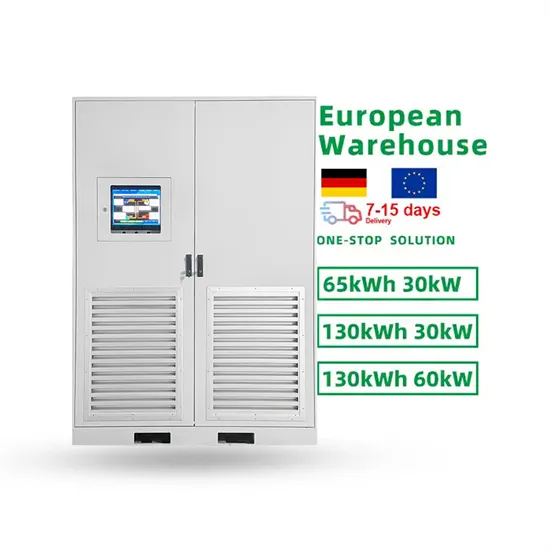

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.