Easier to convert high voltage DC to low voltage DC or high

I am working on a project and I need to create either a high voltage DC to low voltage DC buck converter, or a high voltage DC to 110 AC inverter. 500w would be nice,

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical engineering. These can also be known as

Get Price

Comparison and Analysis of High Voltage Inverter and Low Voltage

Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter technology, the

Get Price

The role and difference between high voltage inverter and low voltage

To summarize, high-voltage inverters are mainly used for high-power applications in industry, while low-voltage inverters are suitable for low-power applications in homes and

Get Price

Low-voltage VS High-voltage Inverters: What''s the Difference

Low-voltage VS High-voltage Inverters: What''s the Difference? Inverter technology serves as the backbone of modern power conversion systems, facilitating the seamless transformation of DC

Get Price

Differences Between Inverter and Voltage Stabilizer

The main function of the inverter Voltage conversion: Converts low-voltage DC to high-voltage AC. Frequency Adjustment: Adjusts the frequency of the output current to match

Get Price

Low-voltage DC/AC inverter, Low-voltage inverter

Find your low-voltage dc/ac inverter easily amongst the 37 products from the leading brands (VEICHI, Santroll, ABSOPULSE Electronics,) on DirectIndustry, the industry specialist for

Get Price

Easier to convert high voltage DC to low voltage DC or high

I am working on a project and I need to create either a high voltage DC to low voltage DC buck converter, or a high voltage DC to 110 AC inverter. 500w would be nice, 300w will work as I

Get Price

Differences and similarities between low-voltage inverters and

The choice between a low-voltage inverter and a high-voltage inverter often depends on specific application requirements, including the scale of the operation, efficiency concerns, and safety

Get Price

High voltage DC-AC sine wave inverters accept wide

The high input voltage DC-AC sine wave inverters are designed for industrial applications that require clean sine wave AC-output voltage. They are suitable

Get Price

Differences and similarities between low-voltage inverters and high

The choice between a low-voltage inverter and a high-voltage inverter often depends on specific application requirements, including the scale of the operation, efficiency concerns, and safety

Get Price

What Is a DC/DC converter in an Electric Vehicle (EV)?

When the battery is charged, a DC/DC converter converts high-voltage DC power into low-voltage DC power. This article will discuss the functions and system configuration of

Get Price

High Voltage High Frequency AC

Looking for high frequency inverter/converter? Micno''s high voltage power inverter (vtd) can be used for energy-saving speed regulation and process

Get Price

The role and difference between high voltage inverter

To summarize, high-voltage inverters are mainly used for high-power applications in industry, while low-voltage inverters are suitable for low

Get Price

Detailed explanation of the method for converting high-voltage

The process of converting high-voltage AC into low-voltage DC is mainly completed through several steps such as rectification, voltage transformation, and filtering.2.

Get Price

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Solutions for Inverter Low Voltage Problems Now that we have identified some potential causes, let''s explore the solutions for inverter low voltage problems. Firstly, if your

Get Price

High-voltage VS Low-voltage Inverters: What''s the difference?

You''ll learn what high-voltage and low-voltage inverters do, how they work, and where each type is best used. We''ll also talk about the benefits and drawbacks of each, along

Get Price

Power inverter

A power inverter, inverter, or invertor is a power electronic device or circuitry that changes direct current (DC) to alternating current (AC). [1] The resulting AC

Get Price

How do electronics (like transformers) convert high voltage, low

The additional voltage can''t come out of nowhere due to thermodynamics, so does it convert the current into voltage? And does that work in the opposite way? So, for instance, say

Get Price

A High Voltage CMOS Voltage Level Converter for a Low

Abstract A new high-voltage CMOS voltage level converter designed for manufacturing in low-voltage technological processes is presented. The features of the

Get Price

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters use high-frequency switches to convert incoming low-voltage DC power to high-frequency low-voltage AC power.

Get Price

High Voltage VS Low Voltage Solar Inverter in Pakistan

High-voltage inverters typically convert DC from high-voltage solar panels or batteries into AC. Such inverters are usually used for systems with batteries having a voltage

Get Price

Whats is a High Voltage Hybrid inverter? What are

Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable

Get Price

Comparison and Analysis of High Voltage Inverter and Low

Adjustable output frequency AC motor drives with voltage levels below 690V are classified as low-voltage inverters. With the continuous maturity of low-voltage inverter technology, the

Get Price

ELI5: How does an inverter convert 12v dc to 120v ac? What''s

A while ago, an electric circuit called an oscillator first converted 12VDC to 12VAC, then a transformer converted low voltage, high current 12V 60Hz AC to high voltage, low current

Get Price

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters use high-frequency switches to convert incoming low-voltage DC power to high-frequency low-voltage AC power.

Get Price

Low voltage DC to High Voltage DC Circuit Explanation

A voltage multiplier circuit is connected to the secondary of the transformer which will give a high voltage dc at the output. That dc voltage is

Get Price

A Low to High Voltage Tolerant Level Shifter for Low Voltage

the interface of a low-voltage and high-voltage gates. The level shifter is a key circuit component in multi-voltage circuits and has important implementation [15]. For a chip-level DVS system,

Get Price

An advanced guide to Understanding DC to AC inverters

It is a mechanism that lets you use low-frequency output signals. 3. OUTPUT FILTER In this step, the output filter removes high-frequency structure from the PWM wave.

Get Price

Whats is a High Voltage Hybrid inverter? What are Key

Explore the pivotal differences between high and low voltage hybrid inverters and how these variations can influence your choice in sustainable energy solutions.

Get Price

More related information

-

Convert low frequency inverter to high frequency

Convert low frequency inverter to high frequency

-

Inverter outputs high voltage and low current

Inverter outputs high voltage and low current

-

Is the communication base station inverter high voltage or low voltage

Is the communication base station inverter high voltage or low voltage

-

Inverter high current voltage becomes low

Inverter high current voltage becomes low

-

High Voltage Inverter 3000

High Voltage Inverter 3000

-

Inverter can convert voltage

Inverter can convert voltage

-

The inverter output voltage is low after rectification

The inverter output voltage is low after rectification

-

Canadian low voltage inverter prices

Canadian low voltage inverter prices

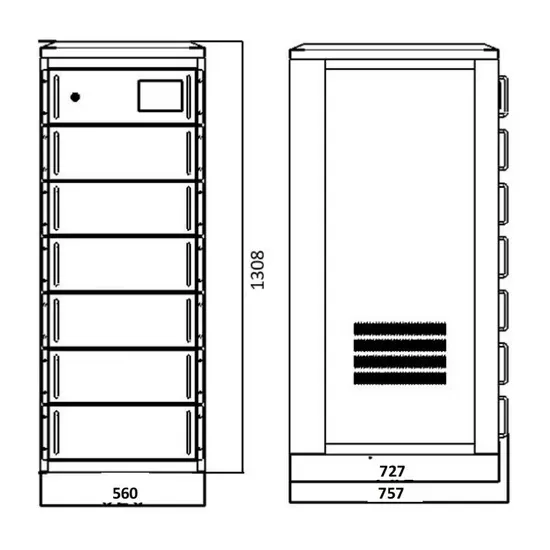

Commercial & Industrial Solar Storage Market Growth

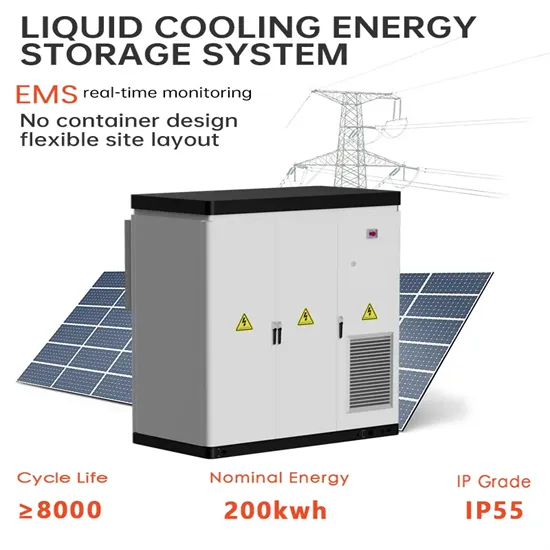

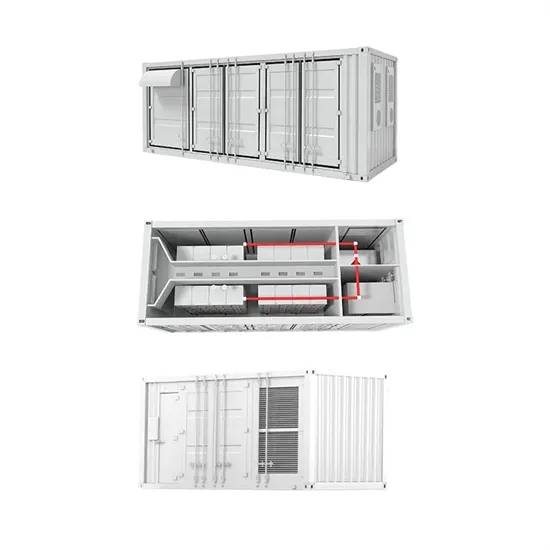

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

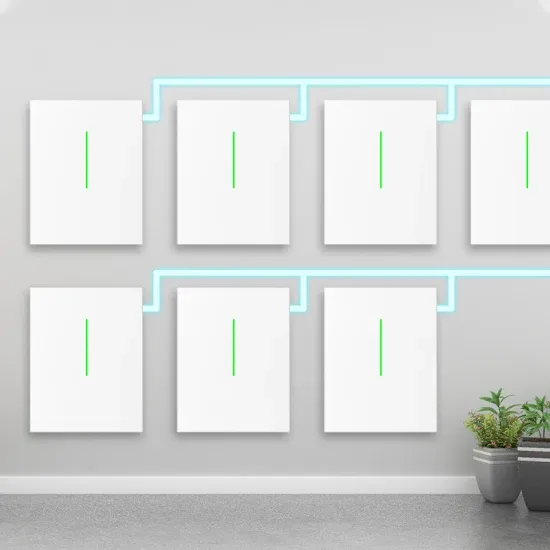

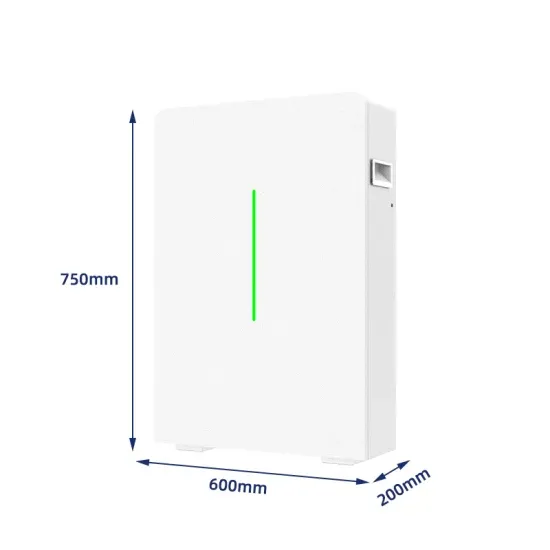

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.