A Detailed Guide about Solar Wafers: Application And

More than half of the utilized pure silicon gets processed to produce solar wafers. The dark-colored panels you see on the roof of your

Get Price

A Detailed Guide about Solar Wafers: Application And Types

More than half of the utilized pure silicon gets processed to produce solar wafers. The dark-colored panels you see on the roof of your house are composed of solar cells. They

Get Price

Solar Cell Production: from silicon wafer to cell

This article explains in detail the production process from sliced silicon wafer disks to the final ready-to-assemble solar cell.

Get Price

A Review of End‐of‐Life Silicon Solar Photovoltaic Modules and

3.1 Silicon Photovoltaics: Structure and Materials The general design and structure of silicon photovoltaic panels are largely similar and can be represented as a number of layers.

Get Price

Solar Cells and Modules | SpringerLink

This book gives a comprehensive introduction to the field of thin-film silicon solar cells and modules. It presents the essential theoretical and practical concepts in an easy-to-understand

Get Price

Fab & analysis of silicon wafer-based PV modules

Introduction In conventional silicon wafer-based PV technology, solar cells are connected in series and encapsulated into PV modules. The interconnection increases the power and voltage,

Get Price

Crystalline Silicon Solar Cell and Module Technology

In the following sections, the technological processes from preparing pure silicon, to silicon wafer fabrication, to cell design and fabrication, and finally to PV module design and

Get Price

What you need to know about polysilicon and its role

Polysilicon, a high-purity form of silicon, is a key raw material in the solar photovoltaic (PV) supply chain. To produce solar modules, polysilicon is

Get Price

Solar Cells and Modules | SpringerLink

This book gives a comprehensive introduction to the field of thin-film silicon solar cells and modules. It presents the essential theoretical and practical concepts

Get Price

What Are Wafer-Based Solar Cells?

While silicon wafers are commonly used in electronics and micromechanical devices, they also play a significant role in energy

Get Price

Crystalline silicon solar cell with an efficiency of 20.05 %

The manufactured solar cell had an efficiency of 20.05 %, which is approximately 0.97 % lower than that of commercial wafer-based solar cells. Moreover, the factors

Get Price

PV cells and modules – State of the art, limits and trends

Over the past 15 years a categorisation of generations of PV cell and module technology groups has been frequently used. The main features of individual technology

Get Price

Review of silicon recovery in the photovoltaic industry

Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Get Price

Solar Cell Production: from silicon wafer to cell

Crystalline silicon cell wafers are formed in three primary types: monocrystalline, polycrystalline, and ribbon silicon. Each type has advantages and disadvantages in terms of

Get Price

Non-destructive recovery of silicon wafers from waste photovoltaic

The continuous increase of waste photovoltaic (PV) modules poses a great challenge to global environmental protection and human health. As the main body of waste PV

Get Price

How Solar Silicon Wafers Are Made into Cells

How Solar Silicon Wafers Are Made into Cells. The process of transforming solar silicon wafers into cells involves several meticulous steps,

Get Price

Thin prospects for ingot, wafer and solar cell

The production of PV ingots and wafers remains the most highly concentrated of all the production stages in the silicon solar supply chain. Yet

Get Price

Crystalline Silicon Module

Crystalline silicon modules refer to solar cell systems designed to maximize efficiency while ensuring safety and reliability, with key challenges in cell interconnection and encapsulation

Get Price

What Is a Silicon Wafer for Solar Cells?

Silicon wafers are by far the most widely used semiconductors in solar panels and other photovoltaic modules. P-type (positive) and N-type (negative) wafers are manufactured and

Get Price

A method to recycle silicon wafer from end-of-life photovoltaic module

This paper details an innovative recycling process to recover silicon (Si) wafer from solar panels. Using these recycled wafers, we fabricated Pb-free

Get Price

Silicon-based Photovoltaics

Scale: Poly-Si production ~120,000 MT/year (over half for PV industry). Slow response to changing demand: Long leadtimes and large cost of capacity expansion result in oscillatory

Get Price

Silicon Solar Cell

Silicon ingots of mono-crystalline crystal or solar-grade poly-crystalline silicon are then sliced by band or wire saw into mono-crystalline and poly-crystalline wafers into 156 × 156 mm 2 size

Get Price

Crystalline Silicon Terrestrial Photovoltaic Cells

Executive Summary and standard that applies to photovoltaic (PV) cells. Many PV module manufacturers depend on third party solar cell manufacturers for their supply of silicon cells.

Get Price

Fabricating Different Types of Photovoltaic Cells

Crystalline silicon cell wafers are formed in three primary types: monocrystalline, polycrystalline, and ribbon silicon. Each type has advantages and disadvantages in terms of

Get Price

Flexible solar cells based on foldable silicon wafers with blunted

Modules of foldable crystalline silicon solar cells retain their power-conversion efficiency after being subjected to bending stress or exposure to air-flow simulations of a

Get Price

How Solar Silicon Wafers Are Made into Cells | NenPower

How Solar Silicon Wafers Are Made into Cells. The process of transforming solar silicon wafers into cells involves several meticulous steps, including wafer slicing, doping, and

Get Price

What Are Wafer-Based Solar Cells?

While silicon wafers are commonly used in electronics and micromechanical devices, they also play a significant role in energy conservation and production. Silicon wafer

Get Price

Trends of Solar Silicon Wafer Size and Thickness for

The PV industry has been rapidly evolving with advancements in wafer size, wafer thickness, and solar cell technologies. These developments

Get Price

Solar Photovoltaic Manufacturing Basics

Most commercially available PV modules rely on crystalline silicon as the absorber material. These modules have several manufacturing steps that typically occur separately from each other.

Get Price

More related information

-

Monocrystalline silicon high-efficiency photovoltaic modules

Monocrystalline silicon high-efficiency photovoltaic modules

-

Huawei photovoltaic modules monocrystalline silicon modules

Huawei photovoltaic modules monocrystalline silicon modules

-

Middle East crystalline silicon photovoltaic modules solar panels

Middle East crystalline silicon photovoltaic modules solar panels

-

Polycrystalline silicon double-glass photovoltaic modules

Polycrystalline silicon double-glass photovoltaic modules

-

Monocrystalline silicon and polycrystalline silicon in photovoltaic modules

Monocrystalline silicon and polycrystalline silicon in photovoltaic modules

-

Are all photovoltaic modules exported

Are all photovoltaic modules exported

-

Price Trend of Large Photovoltaic Modules

Price Trend of Large Photovoltaic Modules

-

Cuban monocrystalline photovoltaic modules and panels

Cuban monocrystalline photovoltaic modules and panels

Commercial & Industrial Solar Storage Market Growth

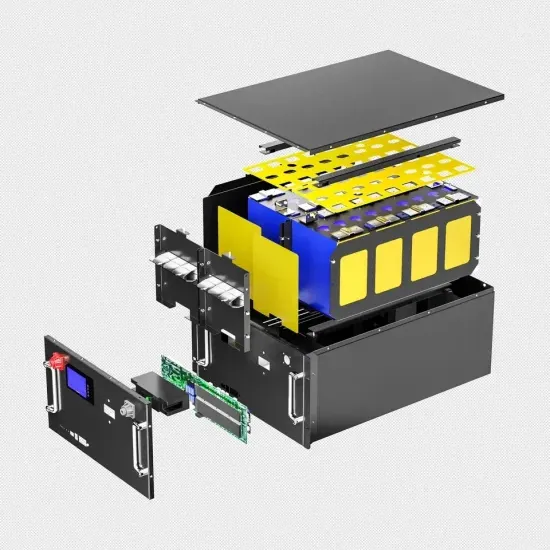

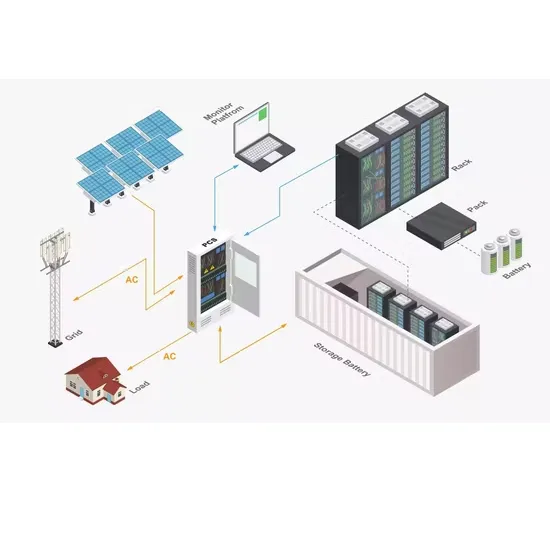

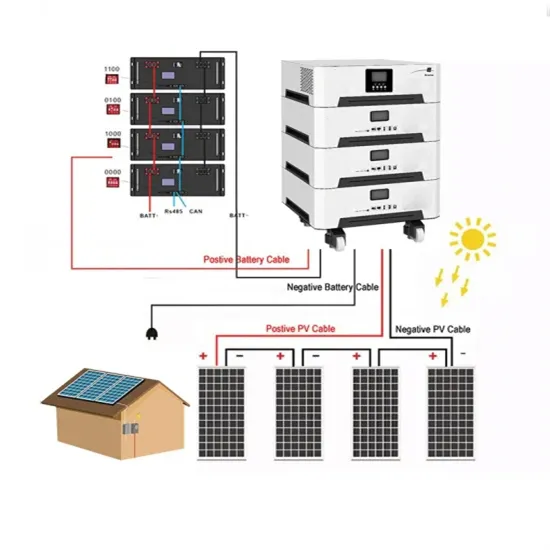

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

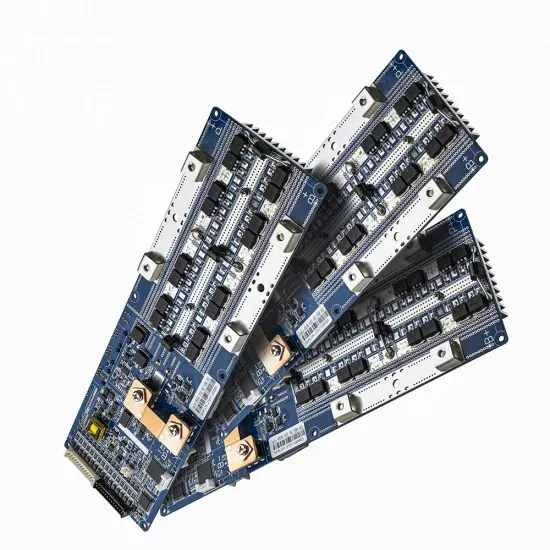

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.