Ventilation and Thermal Management of Stationary Battery

For each battery type, the technology and the design of the battery are described along with the environmental considerations.

Get Price

Peltier TEC Air Conditioner For Electrical Cabinet

Peltier tec air conditioner is a solution that provides temperature control for indoor and outdoor cabinets, and is suitable for various challenging indoor and

Get Price

Battery Room Ventilation and Safety

This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting out a battery

Get Price

Cooling Systems for Electronic Enclosures

Thermoelectric solid-state air conditioners can be a cost-effective solution for cooling electronic/electrical equipment and devices housed in enclosures and cabinets. With relatively

Get Price

What are the ventilation requirements for energy storage cabinets

The primary objective of implementing ventilation requirements is to manage the thermal characteristics of the batteries. An effective ventilation system helps dissipate heat

Get Price

What are the ventilation requirements for energy

The primary objective of implementing ventilation requirements is to manage the thermal characteristics of the batteries. An effective ventilation

Get Price

Battery Energy Storage System Cooling Solutions

This whitepaper from Kooltronic explains how closed-loop enclosure cooling can improve the power storage capacities and reliability of today''s advanced

Get Price

Comparative analysis of battery electric vehicle thermal

In the case of a direct liquid cooling solution, coolant is brought as close as possible to the battery for optimal heat transfer performance while an indirect solution places a cold plate along the

Get Price

ASHRAE TC9.9 Data Center Power Equipment Thermal

ASHRAE TC9.9 Data Center Power Equipment Thermal Guidelines and Best Practices Whitepaper created by ASHRAE Technical Committee (TC) 9.9 Mission Critical Facilities,

Get Price

1635-2022

This guide describes battery operating modes and the hazards associated with each. It provides the HVAC designer with the information to provide a cost effective ventilation

Get Price

Technical requirements for cabinet battery compartment

Providing series combinations by three basic function units,"equipment cabinet, anxiliary cabinet, and storage battery cabinet" 2.Easy configuration according to customer needs.

Get Price

Structural Design of the Refrigerant Direct Cooling Thermal

Abstract. Lithium-ion batteries, as the sole energy source for electric vehicles, have a significant impact on battery capacity, cycle life, and safety due to their thermal characteristics. The direct

Get Price

Electric Vehicle Battery Cooling Methods Are Evolving

Direct cooling: It is also called immersion cooling, where the cells of a battery pack are in direct contact with a liquid coolant that covers the

Get Price

Battery Equipment Heating Cooling Air conditioning

HVAC Heating Air conditioning Free cooling (Thermal management) for Battery Equipment electrical cabinet''s, hybrid solar powered off-grid equipment

Get Price

Managing & maintaining temperature in enclosures

In closed loop cooling, the sealed integrity of the cabinet will be maintained with either an air conditioner or heat exchanger, protecting the equipment from dirt, dust, corrosive air and wind

Get Price

Battery Cabinet Cooling Requirements | HuiJue Group E-Site

As battery chemistries evolve toward solid-state architectures, our cooling paradigms must adapt – perhaps even leveraging quantum tunneling composites for direction-controlled heat transfer.

Get Price

Telecom Electrical Enclosure Cooling: Back to Basics

Many telecom cabinets are located in remote sites, requiring them to operate on battery, solar, or wind power. In these cases, a cooling solution operating on

Get Price

Thermal performance analysis and burning questions of

Through an in-depth analysis of the local temperature distribution of battery units, two burning questions were identified which deteriorate the temperature control performance

Get Price

Checklist: Venting Clearance and Code Rules for Battery Cabinets

Stop battery overheating. This checklist details essential venting clearance and code rules for safe, compliant battery cabinet installation.

Get Price

Battery cabinet plastic shell technical requirements

What should a battery cabinet have? Handles – provides an easy way to handle the battery cabinet. Battery holding brackets – they ensure the battery is always in a fixed position (no

Get Price

Comparison of cooling methods for lithium ion battery

Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Get Price

Thermoelectric Cooling for Base Station and Cell Tower Equipment

Temperature control of sensitive telecom electronics in unattended mobile base stations and cell towers is vital for the operation of primary and back-up systems. Heat can

Get Price

Battery Energy Storage System Cooling Solutions | Kooltronic

This whitepaper from Kooltronic explains how closed-loop enclosure cooling can improve the power storage capacities and reliability of today''s advanced battery energy storage systems.

Get Price

Analysis of the Battery Direct Cooling Thermal Management

To investigate the characteristics of a battery direct-cooling thermal management system integrated with the passenger compartment air-conditioning in a range-extended

Get Price

6 FAQs about [Technical requirements for direct cooling and heating of battery cabinets]

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

What are the requirements for a stationary battery ventilation system?

Ventilation systems for stationary batteries must address human health and safety, fire safety, equipment reliability and safety, as well as human comfort. The ventilation system must prevent the accumulation of hydrogen pockets greater than 1% concentration.

What is thermal management of batteries in stationary installations?

thermal management of batteries in stationary installations. The purpose of the document is to build a bridge betwe the battery system designer and ventilation system designer. As such, it provides information on battery performance characteristics that are influenced by th

What are the requirements for a lead-acid battery ventilation system?

The ventilation system must prevent the accumulation of hydrogen pockets greater than 1% concentration. Flooded lead-acid batteries must be provided with a dedicated ventilation system that exhausts outdoors and prevents circulation of air in other parts of the building.

What is a battery room safety course?

This course describes the hazards associated with batteries and highlights those safety features that must be taken into consideration when designing, constructing and fitting out a battery room. It provides the HVAC designer the information related to cost effective ventilation.

What temperature should a battery be kept at?

1. For optimal battery performance, the battery room temperature should be maintained at a constant 77°F. Temperatures below 77°F increase the battery’s life but decrease its performance during heavy discharge. In room temperatures above 77°F, battery performance increases but its life decreases. 2.

More related information

-

Technical requirements and standards for battery cabinets

Technical requirements and standards for battery cabinets

-

What are the technical requirements for battery cabinets

What are the technical requirements for battery cabinets

-

Top 10 Liquid Cooling Battery Cabinets in the Netherlands

Top 10 Liquid Cooling Battery Cabinets in the Netherlands

-

Is AC direct charging useful for outdoor battery cabinets

Is AC direct charging useful for outdoor battery cabinets

-

Technical requirements for battery cabinet assembly automation

Technical requirements for battery cabinet assembly automation

-

Malaysia New Energy adds battery cabinets

Malaysia New Energy adds battery cabinets

-

Andorra battery energy storage box direct sales price

Andorra battery energy storage box direct sales price

-

Telecom sites can be equipped with battery cabinets

Telecom sites can be equipped with battery cabinets

Commercial & Industrial Solar Storage Market Growth

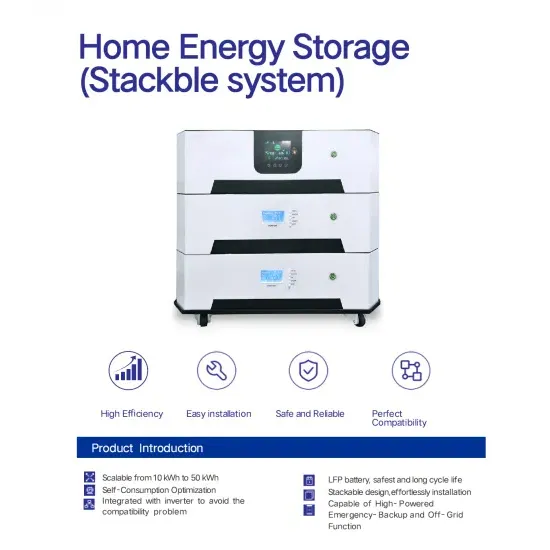

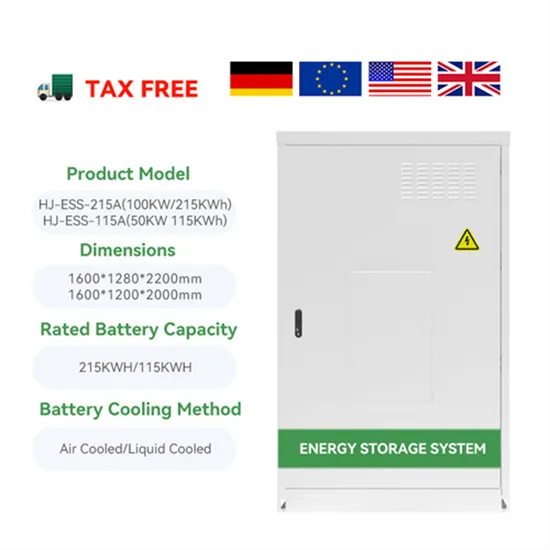

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.