Tesla''s new Shanghai mega-factory pushes out first

Tesla has exported the first shipment of its Megapack batteries from a giant new Shanghai factory, as the energy storage segment of Elon

Get Price

How to Start a Battery Manufacturing Business

Starting a small battery plant can be a great way to stay at the forefront of technology, but don''t expect it to be easy. The first step to starting a battery manufacturing business is to

Get Price

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get Price

How to open a battery manufacturer?

There''s no doubt that starting a battery manufacturing business requires a lot of work, but with expert planning, you''ll be well on your way to creating a

Get Price

Tesla Nearing Completion of First U.S. LFP Battery

Tesla has officially confirmed that it''s nearing completion of its first lithium iron phosphate (LFP) battery cell manufacturing facility in North

Get Price

Panasonic reportedly delays production ramp at US

Panasonic has reportedly delayed its plan to ramp up production at its new battery factory in Kansas due to low demand from Tesla, its primary

Get Price

How to Start a Battery Manufacturing Business

Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

Get Price

How to Start an Electric Vehicle Battery Business in 9

Discover our comprehensive 9-step guide and learn how to navigate this complex industry, from securing funding to establishing

Get Price

Gigafactory

Battery Innovation Center is dedicated to spearheading the development of cutting-edge cell and battery technology, laying the groundwork for our

Get Price

How to Start an Electric Vehicle Battery Business in 9 Steps?

Discover our comprehensive 9-step guide and learn how to navigate this complex industry, from securing funding to establishing production facilities. Ready to power up your

Get Price

Cost Of Lithium-ion Battery Manufacturing Plant & Machinery

This facilitates the development of new technologies and ensures a high-quality product. Here in this article, the cost of a lithium-ion battery manufacturing plant and the types of machinery

Get Price

Tucson Tech: Battery factory advances tech for new factory

American Battery Factory, or ABF, a spinoff of Utah-based battery pack maker Lion Energy, plans to invest $1.2 billion in capital and hire about 1,000 new jobs at full buildout of its

Get Price

Lithium-ion Battery Pack Manufacturing Process

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

Hyundai and LG Energy open Indonesia''s first battery

Hyundai and LG Energy Solution have opened a $1.1bn battery cell plant in Indonesia as the south-east Asian country works to build an electric

Get Price

Skywell Battery Factory Opening Ceremony

Skywell officially launched the factory to produce its own batteries 🌱 With the opening of the battery factory with a capacity of 1.2 GWh, Skywell strengthened its hand in the competition in

Get Price

Tesla announces massive new manufacturing plant in

Tesla has announced plans to build a factory to manufacture its energy storage units in a place where clean energy is booming. According to

Get Price

Arizona KOREPlex Battery Manufacturing Plant

KOREPlex is opening a lithium-ion battery manufacturing plant in Arizona that will be operated by electrical hardware and automatic software

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Price

How To Start a Battery Packaging and Assembly Specialist

Congratulations on completing this guide to launching your battery packaging and assembly business! 🚀 We''ve covered essentials like industry trends, funding, operations, and marketing

Get Price

Elon Musk, Tesla open Megapack battery factory in China amid

Tesla opens Megapack battery factory in China amid nascent trade war The opening of the $200 million Megapack battery plant in Shanghai highlights Elon Musk''s

Get Price

Custom Lithium Battery Pack Manufacturing

In this comprehensive technical guide, I''ll share an in-depth look at our end-to-end custom lithium battery pack manufacturing process.

Get Price

A Global Tour of Upcoming Battery Production Factories

In this article, we will explore five upcoming battery production factories set to open in the coming years.

Get Price

How to open a battery manufacturer?

There''s no doubt that starting a battery manufacturing business requires a lot of work, but with expert planning, you''ll be well on your way to creating a profitable business venture.

Get Price

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get Price

Battery Pack Manufacturing Process: Step-by-Step Guide

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get Price

How To Establish A Battery Pack Manufacturing Factory

Building a battery pack manufacturing factory is a strategic endeavor that requires meticulous planning, technical expertise, and a clear understanding of market demands.

Get Price

Tesla''s Shanghai megapack battery plant launches

Tesla''s battery megafactory in Shanghai, for manufacturing its megapack batteries, has launched production on Tuesday, Chinese official

Get Price

Battery Pack Manufacturing Process: Step-by-Step

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get Price

6 FAQs about [Opening a pack battery factory]

What is the battery pack manufacturing process?

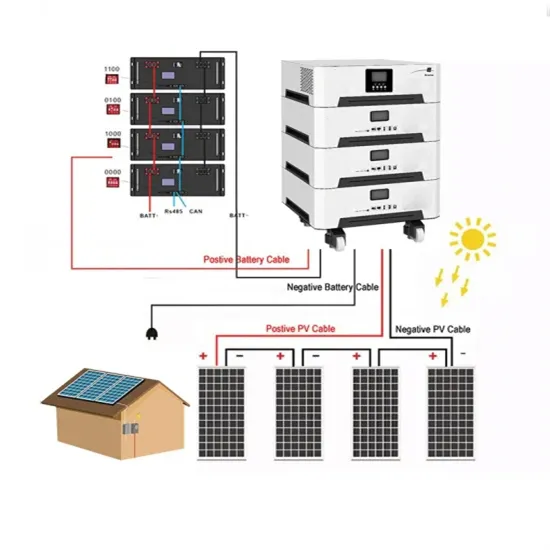

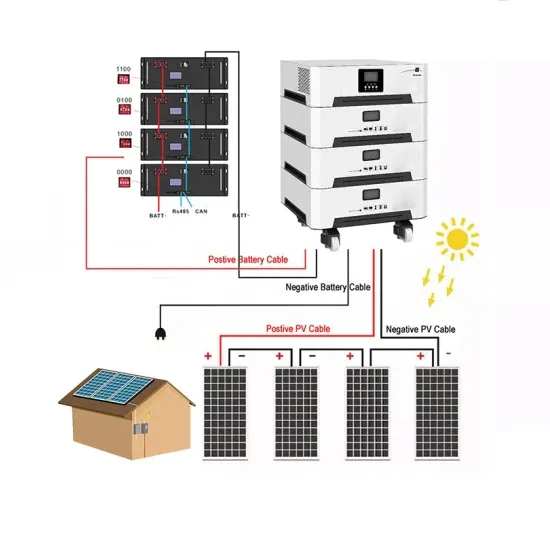

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

How to make a battery pack?

The journey towards crafting a battery pack begins with assembling individual battery cells. These cells, having undergone the transformation process to optimize their electrical performance, are now ready to be connected. Before this, it is essential to clean the surface of the cells thoroughly.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

How do I promote my battery manufacturing business?

Marketing and Advertising: To promote your battery manufacturing business, you will need to allocate funds for marketing and advertising efforts, such as creating a website, attending trade shows, and running social media campaigns.

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

More related information

-

San Marino 32650 lithium battery pack factory

San Marino 32650 lithium battery pack factory

-

Japanese lithium battery pack factory direct sales

Japanese lithium battery pack factory direct sales

-

Tunisia pack battery processing factory

Tunisia pack battery processing factory

-

Qatar good lithium battery pack factory price

Qatar good lithium battery pack factory price

-

East Africa pack battery processing factory

East Africa pack battery processing factory

-

Huawei Slovakia pack lithium battery factory

Huawei Slovakia pack lithium battery factory

-

Mobile pack battery factory

Mobile pack battery factory

-

Pack battery factory in Thailand

Pack battery factory in Thailand

Commercial & Industrial Solar Storage Market Growth

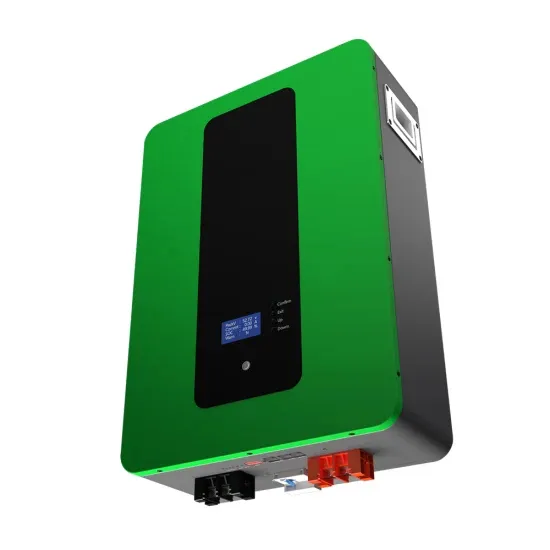

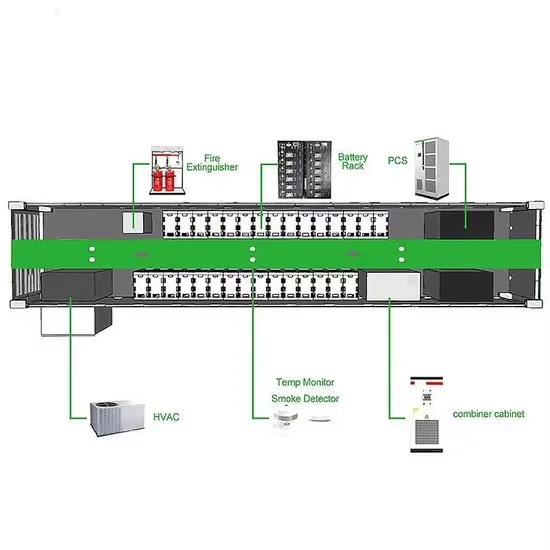

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.