Hungary – the future paradise for EV battery

A sslight overview about the EV battery producer companies which already operate manufacturing plants in Hungary or announced.

Get Price

DTG Industrial Battery Powered Mobile Workstations

DTG''s highly-configurable battery powered mobile workstations help optimize every aspect of your warehouse operations - from receiving and inventory

Get Price

Custom Lithium-ion Battery Pack Manufacturer

Lithium-ion battery pack manufacturing process includes separate cell sorting, assembly, and insulation stages to ensure high performance, safety, and

Get Price

Topping-Out ceremony for MAN''s new battery

It will begin manufacturing high-voltage batteries at the facility starting in April 2025. The batteries produced in Nuremberg will be used in

Get Price

Battery Manufacturers in New Jersey

BatteryZone Inc. Manufacturer and distributor of rechargeable battery systems for two-way radio, cell-phone, laptop computer, digital video/photo, medical, flashlight and much more.

Get Price

Home

1. Precision designed for demanding industriesMilitary-grade durability: 3000+ charge cycles (80% capacity retention), tested in extreme conditions from -20°C

Get Price

Custom Lithium Battery Pack Manufacturing

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves

Get Price

AMP Apex Mobile Power

Apex Mobile Power is a custom battery supplier specializing in OEM lithium battery design and manufacturing. Our high-performance lithium-ion battery packs, custom battery chargers, and

Get Price

"It''s the start of something big"

It was decided back in 2020 to build a mass production facility for battery packs in Nuremberg. With support from the city of Nuremberg and the Free State of Bavaria, together with a €100

Get Price

Lithium Ion Battery Pack Manufacturer | CM Batteries

CMB is a lithium ion battery manufacturer with multiple patents for custom lithium-ion battery packs and lifepo4 battery packs.

Get Price

MAN celebrates completion of works at battery

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on

Get Price

Leafcell-Leading Lithium Battery Pack Manufactures

LEAFCELL, A Leading Manufactures for affordable & best quality lithium-ion and lithium-phosphate battery packs for e-vehicles in India. Customize your battery..

Get Price

China Best LiPo Battery Supplier, Polymer Li-ion Battery

$3.50 Add to Cart Shenzhen 18650 Battery Factory Supply Long Life Electric Forklift Rechargeable Battery BZ 18650-7S4P 25.2V 10.4Ah Li-ion Battery Pack $70.00 Add to

Get Price

MAN celebrates completion of works at battery manufacturing

From April 2025, high-voltage batteries will be manufactured industrially in Nuremberg using state-of-the-art production methods on 17,000square metres. Up to 50,000

Get Price

Mobile Power Carts & Battery Power Workstations

Mobile powered work stations provide power to computers and printers remotely for shipping & receiving processes, inventory management, cross docking,

Get Price

Leading Battery Pack Manufacturers Worldwide: Top 10 List

Explore the top 10 global battery pack manufacturers powering devices from smartphones to EVs, with insights into their innovations and industry impact.

Get Price

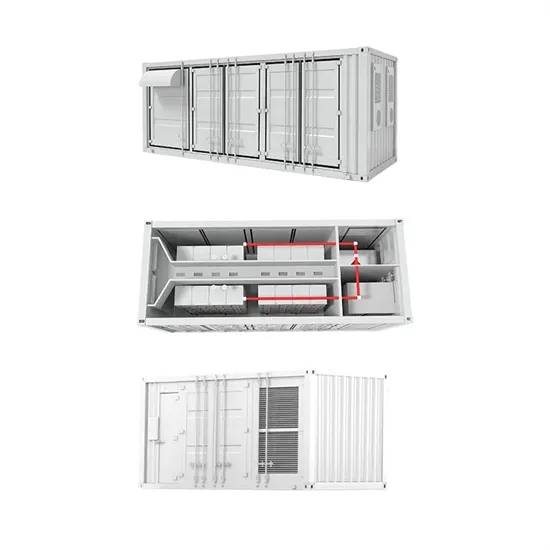

The factory mass-produces 16kwh (51.2V320Ah) battery packs

16kw solar battery stackable 51.2V320Ah mobile battery #pack#battery #lifepo4 #factory #energystorage #lifepo4lithiumbattery #lifepo4storagebattery #lifepo4b

Get Price

Future-oriented decision: MAN builds battery factory in Nuremberg

From the beginning of 2025, MAN Truck & Bus will manufacture high-voltage batteries for electric trucks and buses in large-scale production at its Nuremberg site. To this end, the company will

Get Price

Topping-Out ceremony for MAN''s new battery production facility

It will begin manufacturing high-voltage batteries at the facility starting in April 2025. The batteries produced in Nuremberg will be used in MAN''s new eTruck, the first unit of

Get Price

Home

Precision designed for demanding industries. Military-grade durability: 3000+ charge cycles (80% capacity retention), tested in extreme conditions from -20°C to 60°C (IEC62133/UL certified).

Get Price

Custom Lithium Battery Pack Manufacturing

In this comprehensive technical guide, I''ll share an in-depth look at our end-to-end custom lithium battery pack manufacturing process.

Get Price

Quality Jump Starter Power Packs & Car Battery Jump Starters factory

China leading provider of Jump Starter Power Packs and Car Battery Jump Starters, Shenzhen XUWEN Technology Co.,Ltd is Car Battery Jump Starters factory.

Get Price

Custom Lithium-ion Battery Pack Manufacturer & Assembly

Lithium-ion battery pack manufacturing process includes separate cell sorting, assembly, and insulation stages to ensure high performance, safety, and longevity for all of our custom

Get Price

6 FAQs about [Mobile pack battery factory]

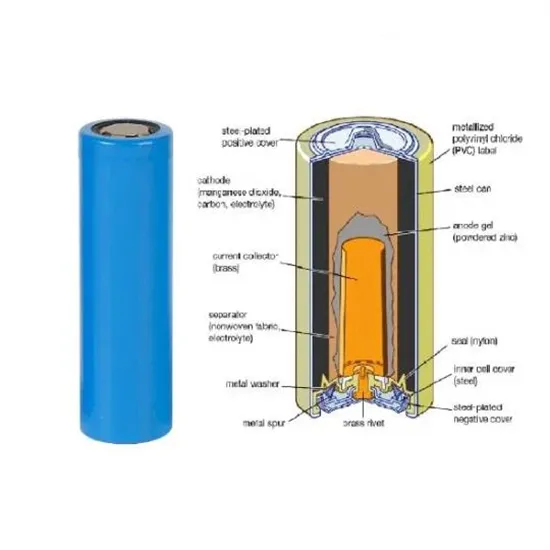

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is a battery pack?

A battery pack is a set of identical batteries or individual battery cells. It can be configured in series, parallel, or a combination to deliver the desired voltage, capacity, or power density. Battery packs provide the necessary energy to power various electronic devices and systems. Part 3. Top 10 battery pack manufacturers’ reviews 1.

What is a custom battery pack assembly service?

CMB’s custom battery pack assembly services involve evaluating battery chemistries, casing design, and management systems based on customer needs. The process encompasses basic and advanced lithium battery pack design features, each tailored to meet specific requirements.

How is Industry 4.0 transforming battery pack manufacturing?

Manufacturing innovations are revolutionizing production efficiency: Industry 4.0 integration enables real-time monitoring and adaptive process control throughout battery pack assembly, significantly reducing defect rates while improving traceability. Emerging technologies will transform battery pack manufacturing:

How will emerging technologies transform battery pack manufacturing?

Emerging technologies will transform battery pack manufacturing: These developments collectively point toward battery packs with higher energy density, longer lifespan, faster manufacturing times, and substantially improved environmental credentials.

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

More related information

-

Pack battery factory in Thailand

Pack battery factory in Thailand

-

Bolivia pack lithium battery factory

Bolivia pack lithium battery factory

-

Opening a pack battery factory

Opening a pack battery factory

-

Dominican lithium battery pack processing factory

Dominican lithium battery pack processing factory

-

Lithium battery pack shipped from the factory

Lithium battery pack shipped from the factory

-

12v lithium battery pack mobile power supply

12v lithium battery pack mobile power supply

-

Angola pack battery factory

Angola pack battery factory

-

East Africa pack battery processing factory

East Africa pack battery processing factory

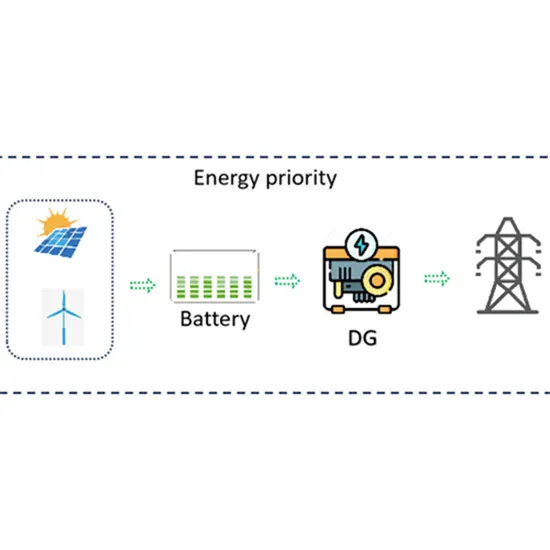

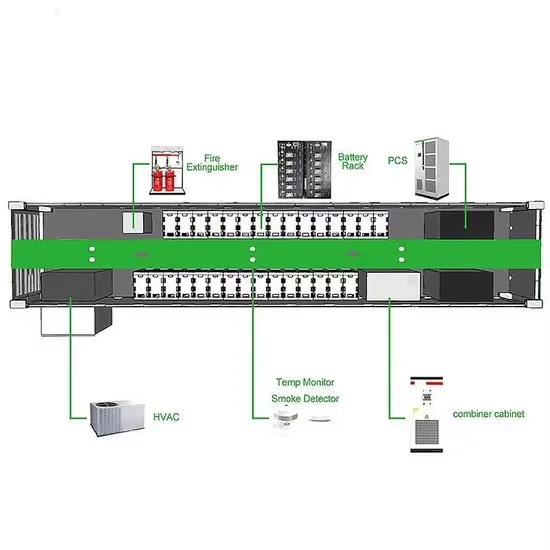

Commercial & Industrial Solar Storage Market Growth

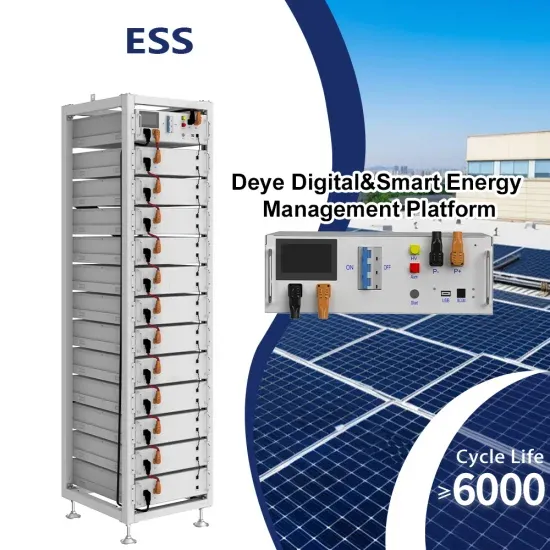

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

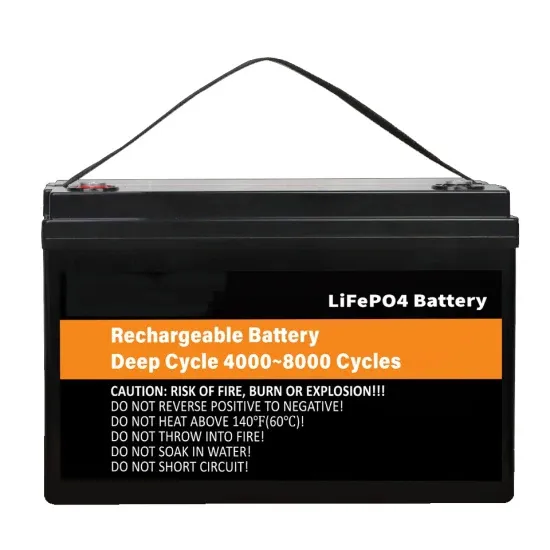

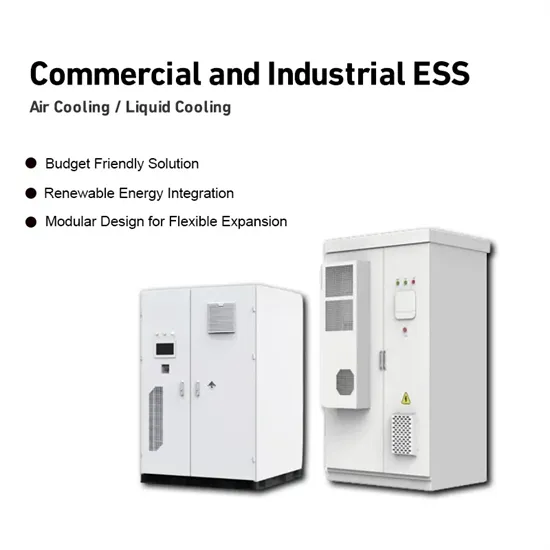

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.