Inverter model

Overview The inverter model simulates the conversion of DC electrical input—derived from PV module IV curves—into AC output suitable for grid connection. It

Get Price

Growatt settings fine tuning

At a point where there is no sun available (i.e. PV power production = 0W), the inverter switches to utility power (Eskom) which uses a considerable amount of utility power to

Get Price

Capacitor Voltage Balancing with Online Controller

The main purpose of the online tuning mechanism is to fine tune the proportional gain according to the DC input voltage, based on the

Get Price

The Most Comprehensive Guide to Grid-Tied Inverter

Detailed Parameters of Grid-Tied Inverters Model and Naming Growatt grid-tied inverters are named based on their rated AC output power. For example, the

Get Price

Refining the Skill of Calibrating Inverter Circuit Boards

In conclusion, mastering the art of calibrating inverter circuit boards is essential for anyone working with power inverters. Understanding

Get Price

Hitachi series inverter 22, B Group: Fine-tuning Functions

1 24 34 34 Download 34 pages, 352.7 Kb 22"B" Group: Fine-tuning Functions A146 ADD direction select • 00 Plus (adds A145 value to output frequency) • 01 Minus (subtracts A145 value from

Get Price

How to Adjust Line out Converter Gain

Adjusting gain controls on a line out converter can be a challenging task for many. In this article, we will show you how to adjust line

Get Price

How to Optimize Your Inverter Settings for Solar Panels

Set the Correct Input Voltage Range. The inverter''s input voltage range determines the voltage at which the solar panel array will operate. Choosing

Get Price

Measurement of Inverter Efficiency

Measurement of Inverter Efficiency Measuring Efficiency with High Precision: Simultaneous Measurement of Input and Output Achieve precise measurement of inverter efficiency by

Get Price

Voltage Control Techniques for Inverters:

Variable voltage variable frequency supply to the motor is obtained within the Inverter Control itself using suitable control based on the principles of PWM or PSM (phase shift modulation).

Get Price

9. Inverter Settings

4. To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be set at least

Get Price

Avoiding common issues when tuning an inverter to

To save time and create efficiency in this transition, it''s important to give proper consideration to a number of factors when tuning an inverter to

Get Price

9. Inverter Settings

When the charge controller goes into equalization mode, the voltage at the battery terminals exceeds the voltage at which the inverter trips off, about 14.5V. Is there a way to

Get Price

Properly Selecting and Tuning an Inverter to an Electric Motor

The key to optimizing the performance of electric equipment is properly selecting and configuring the inverter to the electric motor, which consists of setting the proper motor

Get Price

Advanced Inverter Drive Parameter Settings

Advanced inverter drive parameters unlock powerful capabilities that enhance performance, efficiency, and system reliability. By understanding and fine-tuning these

Get Price

Optimizing Inverter Power Supply with Planar Transformers and

Advantages of Planar Transformers Why are planar transformers considered for such applications? A typical inverter consists of a vertically stacked configuration of a power

Get Price

DAT410 Installation/Operation

The need for this test configuration is mandated by the measurement of rated or nearly rated inverter input current while having a relatively low transformer primary voltage measurement,

Get Price

sj300.book(ch3.fm)

The automatic voltage regulation (AVR) feature keeps the inverter output voltage at a relatively constant amplitude during power input fluctuations. This can be useful if the installa-tion is

Get Price

How to Optimize Your Inverter Settings for Solar Panels

Set the Correct Input Voltage Range. The inverter''s input voltage range determines the voltage at which the solar panel array will operate. Choosing the ideal range is crucial to prevent

Get Price

Optimize Your Solar Inverter Settings Today!

Master your solar inverter settings to boost efficiency and performance. Discover tailor-made strategies for Kenya''s solar power systems.

Get Price

Voltage Control Methods of Inverter – PWM Technique

External Control of AC Output Voltage External Control of DC Input Voltage Internal control of Inverter. External Control of AC Output

Get Price

MIG Welder Settings Explained (with Chart)

Which MIG Settings Matter Most? Although your welder may have a nice selection of adjustments, it''s important to understand that most of them

Get Price

Controlling input voltage to inverter

When the charge controller goes into equalization mode, the voltage at the battery terminals exceeds the voltage at which the inverter trips off, about 14.5V. Is there a way to

Get Price

Application of the VCD-2000 Inverter in Circular Looms: A

Connect the three-phase AC380V (or AC220V, depending on the model) power supply to the inverter input terminals R, S, T. If it is a single-phase model, connect only two

Get Price

Properly Selecting and Tuning an Inverter to an

The key to optimizing the performance of electric equipment is properly selecting and configuring the inverter to the electric motor, which

Get Price

Avoiding common issues when tuning an inverter to an electric

To save time and create efficiency in this transition, it''s important to give proper consideration to a number of factors when tuning an inverter to an electric motor.

Get Price

Growatt settings fine tuning

At a point where there is no sun available (i.e. PV power production = 0W), the inverter switches to utility power (Eskom) which uses a

Get Price

Parameters

Motor Parameters The parameters to adjust the inverter to the motor are boost, fweak, fslipmin, fslipmax, polepairs, fmin, fmax and numimp. They can be deduced from the motors nameplate

Get Price

Advanced Inverter Drive Parameter Settings

Advanced inverter drive parameters unlock powerful capabilities that enhance performance, efficiency, and system reliability. By understanding

Get Price

Refining the Skill of Calibrating Inverter Circuit Boards

In conclusion, mastering the art of calibrating inverter circuit boards is essential for anyone working with power inverters. Understanding the factors affecting calibration, such as

Get Price

9. Inverter Settings

To set the voltage at which the inverter restarts after low voltage shut-down. - To prevent rapid fluctuation between shut-down and start up, it is recommended that this value be set at least

Get Price

Voltage Control Techniques for Inverters:

Variable voltage variable frequency supply to the motor is obtained within the Inverter Control itself using suitable control based on the principles of PWM or

Get Price

6 FAQs about [Inverter input voltage fine-tuning]

What are inverter settings?

Inverter Settings 1. To set output voltage of inverter - This is normally 230 Vac. Possible values 210V ~ 245V. 2. Used to enable/disable the internal ground relay functionality. Connection between N and PE during inverter operation. - The ground relay is useful when an earth-leakage circuit-breaker is part of the installation.

Why do inverters commutate at a low frequency?

But at very low frequencies, the dc link voltage may be too low to commutate the inverter. This limits the lowest operating frequency and hence the frequency range.

What are voltage control techniques for inverters?

This is required to avoid saturation and ensure operation at constant flux density. The Voltage Control Techniques for Inverters can be affected either external to the Inverter Control or within it. The Voltage Control Techniques for Inverters can be done in two ways. (a) The variation of dc link voltage can be achieved in many ways.

How much power does an inverter use?

No geysers / ovens connected to the inverter system. General average power usage on the inverters during the day at any given time is under 1000W (probably 500w average), except for when the microwave/toaster/iron/aircon is being utilised. What do I want to achieve? - using as little as possible of Eskom power. The problem?

What are the disadvantages of a DC link inverter?

The main disadvantage of this method is that the transformer has to be designed for low frequencies and its size is large. The system also has an extremely poor dynamic response. Voltage control within the Inverter: The dc link voltage is constant and the inverter is controlled to provide-both variable voltage and variable frequency.

Why are inverter drives important for industrial automation?

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic parameters like voltage, frequency, and acceleration are well-known, advanced parameter settings allow for greater performance optimization, system protection, and intelligent automation.

More related information

-

What is the input voltage of a 100kw inverter

What is the input voltage of a 100kw inverter

-

What is the maximum input voltage of a 48v inverter

What is the maximum input voltage of a 48v inverter

-

Judge the inverter input voltage

Judge the inverter input voltage

-

Inverter input voltage DC12DC24

Inverter input voltage DC12DC24

-

72V inverter changing input voltage

72V inverter changing input voltage

-

What is the inverter input voltage

What is the inverter input voltage

-

What is the input voltage range of the 48v inverter

What is the input voltage range of the 48v inverter

-

There are several types of input voltage for inverter

There are several types of input voltage for inverter

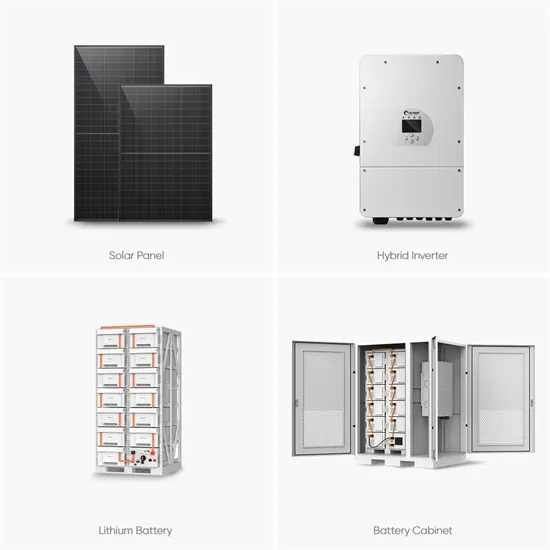

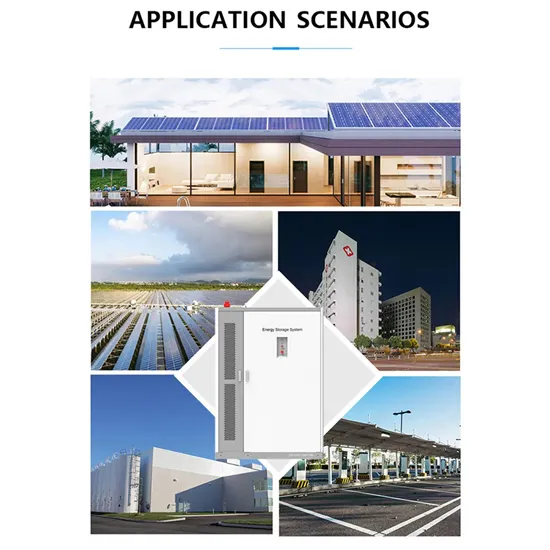

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

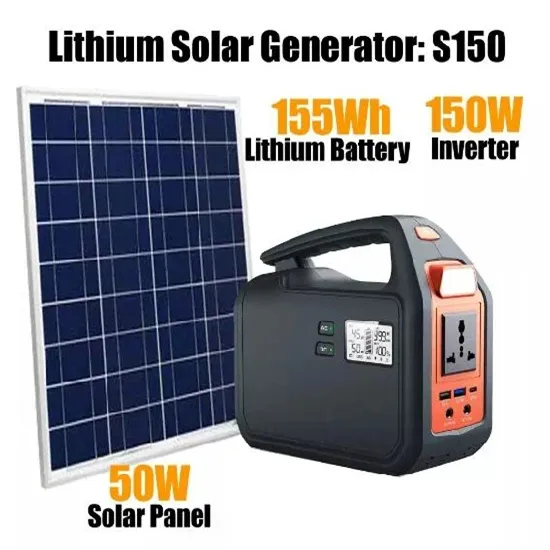

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.