Introduction to Grid Forming Inverters

Why do we need Grid-forming (GFM) Inverters in the Bulk Power System? There is a rapid increase in the amount of inverter-based resources (IBRs) on the grid from Solar PV, Wind,

Get Price

Industrial Solar Power Systems: What You Need to Know

Curious about industrial solar power systems? Here''s what you need to know: With the increasing demand for renewable energy sources, industrial solar power systems have

Get Price

The Ultimate Guide to Commercial Solar Power System for Factories

Discover the advantages of implementing a commercial solar power system for factories in our comprehensive guide. Learn how a well-designed commercial solar power

Get Price

How to Choose the Right Inverter for Your Factory

Choosing the right inverter is essential for the efficiency and lifespan of the solar cell system in your factory. In this article, we will discuss

Get Price

What are the Factors Affecting the Lifespan of Photovoltaic Inverters

Remote monitoring systems can track real-time inverter status, enabling early detection of abnormalities. Conclusion The lifespan of PV inverters is influenced by multiple

Get Price

Industrial Solar Power Systems: What You Need to

Curious about industrial solar power systems? Here''s what you need to know: With the increasing demand for renewable energy sources,

Get Price

What can photovoltaic inverters in electronics factories do

A photovoltaic inverter, also known as a solar inverter, is an essential component of a solar energy system. Its primary function is to convert the direct current (DC) generated by

Get Price

Beginner''s Guide to Solar System for Factories and Industrial

Depending on plant size and load distribution, factories may opt for central inverters (for large setups) or string inverters (for modular control). Their selection is crucial to how

Get Price

Solar Manufacturing

Aside from panels and their components and input materials (such as silicon metal and polysilicon or cadmium telluride powder), there are many different manufactured products that are

Get Price

Standards and Requirements for Solar Equipment,

Installation on of rooftop solar PV systems raises issues related to building, fire, and electrical codes. Because rooftop solar is a relatively new technology and often added to a building after

Get Price

Wind and solar energy solutions

Solar energy photovoltaic (PV) balance of system (BOS) component testing and certification This form of testing covers a wide range of components such as solar PV inverters, cables,

Get Price

What Is an Inverter for Solar Panels and Why Does It

When exploring solar energy for your home or business, one of the most important components you''ll need to understand is the solar inverter.

Get Price

Powering Manufacturing Plants with Solar:

Solar power doesn''t just replace traditional energy sources—it redefines the way factories operate, combining advanced engineering with environmental

Get Price

PHOTOVOLTAIC MODULES AND INVERTERS

Inverters were added in 2019. In 2023, GEC added low-carbon performance criteria that require PV manufacturers to meet a stringent GHG emission threshold for module production,

Get Price

An Introduction to Inverters for Photovoltaic (PV) Applications

PV Inverter Architecture Let''s now focus on the particular architecture of the photovoltaic inverters. There are a lot of different design choices made by manufacturers that

Get Price

Understanding Power Optimizers

A power optimizer or solar optimizer is an electrical component that can be added into a solar power system. It is not a type of solar inverter,

Get Price

Solar Power Plant – Types, Components, Layout and

How a Photovoltaic Power Plant Works? Types of Solar Power Plant, Its construction, working, advantages and disadvantages.

Get Price

What is a photovoltaic inverter?Selection, Principles & Future

A photovoltaic inverter (PV Inverter), also known as a solar inverter, is a power electronic device. Its core function is to convert the direct current (DC) generated by solar

Get Price

Powering Manufacturing Plants with Solar: Engineering the

Solar power doesn''t just replace traditional energy sources—it redefines the way factories operate, combining advanced engineering with environmental responsibility to create smarter,

Get Price

How to Choose the Right Inverter for Your Factory

Choosing the right inverter is essential for the efficiency and lifespan of the solar cell system in your factory. In this article, we will discuss the critical factors in selecting an

Get Price

Solar power solutions

OVR PV T1-T2 QS Series Complete Protection of Photovoltaic (PV) systems completes divestment of solar inverter business to FIMER SpA has completed its divestment of its

Get Price

Solar Photovoltaic Manufacturing Basics

Power electronics for PV modules, including power optimizers and inverters, are assembled on electronic circuit boards. This hardware converts direct current (DC) electricity, which is what a

Get Price

The Ultimate Guide to Commercial Solar Power

Discover the advantages of implementing a commercial solar power system for factories in our comprehensive guide. Learn how a well-designed

Get Price

Solar Manufacturing

Aside from panels and their components and input materials (such as silicon metal and polysilicon or cadmium telluride powder), there are many different

Get Price

Global Inverter Manufacturing Locations

Solar Power World has compiled a list of global solar inverter and optimizer headquarters and manufacturing locations that produce inverters for the

Get Price

What does a solar electronics factory do specifically?

Given the increasing demand for clean and sustainable energy solutions, the role of solar electronics factories has never been more crucial. This article will unravel the various

Get Price

Microinverters: Everything You Need to Know in 2025

In this guide, you''ll learn what microinverters are, compare them to string inverters and learn the top microinverter models and their costs.

Get Price

MNRE issues guidelines for approval of solar inverters

The Solar Photovoltaics Systems, Devices and Components Goods (Requirements for Compulsory Registration) Order 2017 prohibits sales, import or distribution of goods that do

Get Price

Factory inspection specifications for photovoltaic inverters

Why do solar PV system installers need to identify defective inverters? This approach helps solar pv system installers to prevent time consuming problemswhen defective

Get Price

6 FAQs about [Do component factories need photovoltaic inverters ]

Is solar power the future of manufacturing?

As manufacturing plants look to reduce costs and minimize their environmental footprint, solar energy emerges as a powerful solution. Solar power doesn’t just replace traditional energy sources—it redefines the way factories operate, combining advanced engineering with environmental responsibility to create smarter, greener industrial processes.

How can solar energy be used in manufacturing?

Implementing solar energy in manufacturing requires a structured engineering approach to align renewable energy systems with operational workflows. Large automotive companies, for example, have successfully integrated solar solutions into their facilities by collaborating with engineering teams to optimize energy flow and system design.

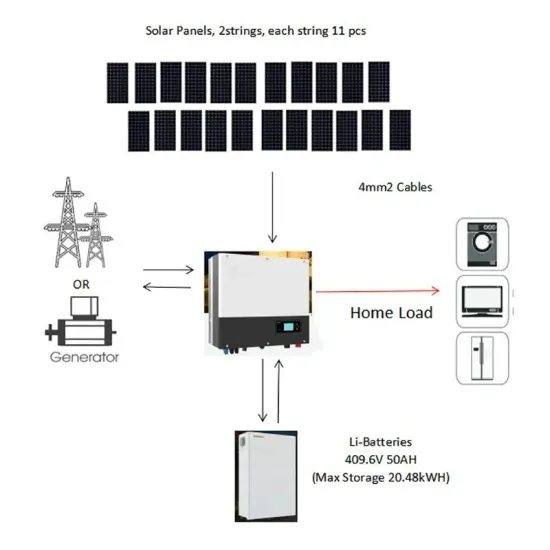

What is a photovoltaic (PV) system?

Photovoltaic (PV) Systems: Ideal for general electricity needs and low-energy tasks, these systems are engineered for efficiency and durability. By combining these technologies, manufacturing facilities can create hybrid systems tailored to their unique energy profiles.

Can rooftop solar power a manufacturing unit?

Key areas where rooftop solar for manufacturing units prove effective include running energy-intensive machines like chillers, air compressors, furnaces, extrusion lines, and injection molding systems. This not only ensures continuous power supply but also significantly lowers peak demand charges from the utility grid.

Can a large automotive company integrate solar systems into their facilities?

Large automotive companies, for example, have successfully integrated solar solutions into their facilities by collaborating with engineering teams to optimize energy flow and system design. One challenge often faced is balancing costs and space utilization.

How do manufacturing plants benefit from solar energy?

Manufacturing plants benefit from technologies designed to meet their specific energy demands: Concentrated Solar Power (CSP): Engineered for high-temperature industrial applications like chemical processing, CSP systems provide a sustainable alternative to traditional heating methods.

More related information

-

Photovoltaic project component random inspection ratio

Photovoltaic project component random inspection ratio

-

Does rural photovoltaic need energy storage

Does rural photovoltaic need energy storage

-

Can photovoltaic inverters be connected in series

Can photovoltaic inverters be connected in series

-

Photovoltaic panel inverters of different specifications

Photovoltaic panel inverters of different specifications

-

Photovoltaic power generation is converted through inverters

Photovoltaic power generation is converted through inverters

-

What is the best DC voltage for photovoltaic inverters

What is the best DC voltage for photovoltaic inverters

-

How big of an inverter do I need for a 39kw photovoltaic system

How big of an inverter do I need for a 39kw photovoltaic system

-

Production of small photovoltaic inverters

Production of small photovoltaic inverters

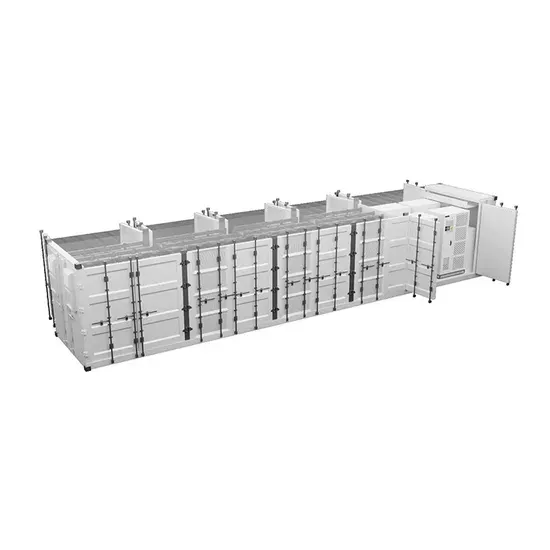

Commercial & Industrial Solar Storage Market Growth

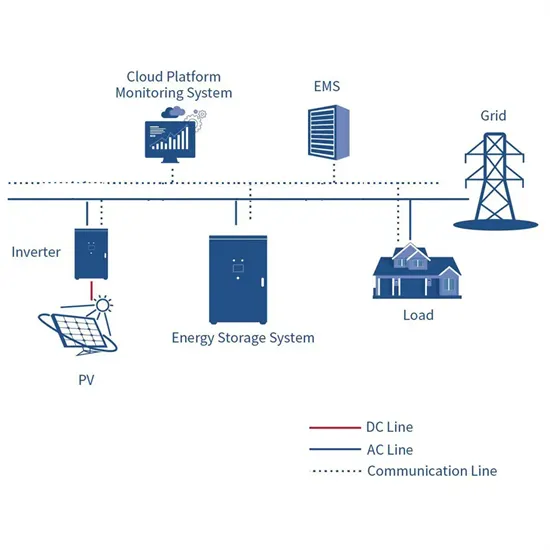

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.