How to Design and Implement a PWM Motor Control Circuit

Pulse Width Modulation (PWM) is one of the most effective techniques used to control the speed of DC motors. It is widely used in applications such as robotics, fans, pumps,

Get Price

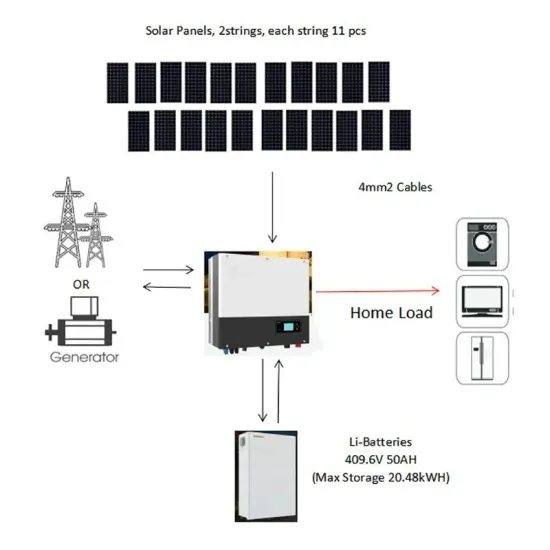

Off-Grid Inverter Installation Guide: Step-by-Step Wiring

In a world increasingly focused on energy independence, off-grid inverter have emerged as the cornerstone of sustainable power systems. Whether you''re powering a remote

Get Price

How to Model Motor, Inverter, and Controller | Field-Oriented

From the series: Field-Oriented Control of Induction Motors with Simulink Learn to model a field-oriented controller architecture with Simulink ® and Simscape Electrical™ for an induction motor. Customize the model for your application by adjusting motor, inverter, and

Get Price

Induction Motor Speed Control

Induction motor speed control is a process of manipulating currents in an induction motor to regulate speed. While often used in fixed frequency

Get Price

Design of Inverter for BLDC Motor

Abstract – This paper present a hardware design of voltage source inverter fed BLDC motor. A general overview of BLDC motor, including its advantages over traditional motor is discussed

Get Price

How to Build a 12V Inverter Circuit Diagram: A Step

In this step-by-step guide, we will show you how to build a 12V inverter circuit diagram, enabling you to power AC appliances or other electronic devices

Get Price

How to Install and Wire an Inverter: A Step-by-Step Wiring

Properly connecting the DC input, AC output, and grounding will ensure efficient and reliable power conversion from the battery to the AC power supply. By following these guidelines, you

Get Price

How an Inverter Drive Works and Controls the Speed of an AC

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

How to Improve Power Conversion Efficiency of Inverters

4. 300-450V DC for electric vehicle battery packs in vehicle-to-grid systems 5. Hundreds of thousands of volts for high power transmission

Get Price

Everything You Need to Know About Inverters: Types,

Unlock the potential of power supply with our comprehensive guide on all about inverters - discover types, benefits, and tips for the perfect

Get Price

Inverter Integration & Implementation Guide

After selecting a motor for an application, inverter selection can start. You then need to go through requirements gathering and assessment, pairing, inverter configuration

Get Price

HOW-TO | install a Motor-mounted frequency inverter

This video walks you through the steps of the installation of a motor-mounted frequency inverter. This general exchange video is intended as a guide, along with the user manual which is...

Get Price

DC-to-AC Converters (Inverters): Design, Working

DC-to-AC converters, also known as inverters, play a crucial role in many different applications due to their ability to convert direct current (DC)

Get Price

How to Install and Wire an Inverter: A Step-by-Step

Properly connecting the DC input, AC output, and grounding will ensure efficient and reliable power conversion from the battery to the AC power supply. By

Get Price

DC Motor Soft Start: Understand and Creating Your

Electric motors often require a high amount of power at start-up, which can lead to potential overloads if the power supply is insufficient. Implementing a soft start

Get Price

How to Design an Inverter – Theory and Tutorial

In this post I have explained the fundamental tips and theories which may be useful for the newcomers while designing or dealing with basic inverter concepts. I have explained

Get Price

230-V/250-W, Hi-η Sensorless Brushless DC Motor Drive

TI Designs The TIDA-00472 is a discrete IGBT-based three-phase inverter for driving brushless DC (BLDC) motors rated up to 250 W using the sensorless, trapezoidal control method. Such

Get Price

Build this 3 Phase Inverter Circuit with Arduino: Full

A circuit that uses a programmable Arduino-based oscillator to generate a three-phase AC output is known as an Arduino three-phase

Get Price

How to Use Pulse Width Modulation (PWM) in Motor

Learn how to control motor speed using PWM. This guide covers setup, duty cycles, components, and troubleshooting for smooth, efficient

Get Price

DC-to-AC Converters (Inverters): Design, Working &

The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or

Get Price

Arduino uno driving dc motor in both directions forward and backward

In this tutorial i am going to teach you how to drive a small DC (direct current) motor with arduino uno using L293D h-bridge motor driver ic. I will control the rotation direction (clock

Get Price

A Complete Guide to Inverters/Variable Frequency

In this article, we will take a look at what an inverter is, where inverters are used, why we use them, and finally some of the most frequently

Get Price

Simplest Inverter With Just a DC Motor 12V to 220V AC

In this instructable, you will learn to make a simple inverter at home.This inverter does not requires multiple electronic components but a single component which is a small 3V DC

Get Price

How to Build a 12V Inverter Circuit Diagram: A Step-by-Step Guide

In this step-by-step guide, we will show you how to build a 12V inverter circuit diagram, enabling you to power AC appliances or other electronic devices using a 12V DC power source.

Get Price

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

DC-to-AC Converters (Inverters): Design, Working & Applications

DC-to-AC converters, also known as inverters, play a crucial role in many different applications due to their ability to convert direct current (DC) to alternating current (AC).

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

In this article, we will take a look at what an inverter is, where inverters are used, why we use them, and finally some of the most frequently asked questions about inverters/VFDs.

Get Price

How to Design an Inverter – Theory and Tutorial

In this instructable, you will learn to make a simple inverter at home.This inverter does not requires multiple electronic components but a single component

Get Price

AC Motor Inverters: How They Work, Principles, And Technical

In summary, AC motor inverters function by converting DC to AC through switching and modulation techniques while enhancing energy efficiency, enabling precise

Get Price

6 FAQs about [How to implement an inverter for a DC motor]

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

How does a DC inverter work?

The DC source provides the initial electrical power that the inverter converts into AC power. This source can come from batteries or a direct current supply. The efficiency of the inverter depends on the stability and capacity of this source. The inverter circuit is responsible for converting the direct current into alternating current.

How do inverters convert DC voltage to AC voltage?

Most inverters rely on resistors, capacitors, transistors, and other circuit devices for converting DC Voltage to AC Voltage. In alternating current, the current changes direction and flows forward and backward. The current whose direction changes periodically is called an alternating current (AC). It has non-zero frequency.

What does an inverter do?

Inverters take AC mains and rectify it into DC. They are components that also can turn DC current into AC current. They are known by a number of different names but the correct term is actually a frequency converter. In an electrical system, they will sit between the power supply and the motor.

How to build a 12V inverter circuit?

Building a 12V inverter circuit requires a detailed understanding of the components and their connections. In order to create a well-functioning inverter, a circuit diagram is essential. The circuit diagram acts as a visual representation of how different components are connected to convert the 12V DC input into 220V AC output.

What is the main power source for an inverter circuit?

12V Battery: The main power source for the inverter circuit is a 12V battery. This battery supplies the DC voltage required to operate the inverter circuit. DC to AC Converter: One of the main components of the inverter circuit is the DC to AC converter, which is responsible for converting the DC voltage from the battery into AC voltage.

More related information

-

DC inverter controlled motor

DC inverter controlled motor

-

What size inverter should I use for a 1kW DC motor

What size inverter should I use for a 1kW DC motor

-

How much DC current does an 800w inverter require

How much DC current does an 800w inverter require

-

How much does a 10KW DC inverter cost

How much does a 10KW DC inverter cost

-

How big an inverter does an 850w AC motor need

How big an inverter does an 850w AC motor need

-

How many kilowatts does a DC inverter have

How many kilowatts does a DC inverter have

-

Water pump inverter DC motor inverter

Water pump inverter DC motor inverter

-

How big an inverter does a 2kW motor require

How big an inverter does a 2kW motor require

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.