Basics of inverter current control system and application to motor

Conclusion Inverter current control systems are invaluable in both industry and everyday life. By converting DC to AC, they ensure the smooth functioning of numerous

Get Price

What is an Inverter Drive and what are its features?

Inverter drives offer several advantages, including energy savings, improved process control, and reduced mechanical stress on the driven

Get Price

DC INVERTER AC TECHNOLOGY

The DC Inverter AC technology is the most recent advancement of innovation concerning the electromotors of the blowers. An Inverter is utilized to control the speed of the blower motor, in

Get Price

Exploring Motor Control Terms: What is an Inverter?

The main task of motor control or drive devices is to take the raw AC voltage coming from the supply source and convert it into a more stable and

Get Price

DC-AC Inverter Circuit

In order to control the output voltage supplied to a motor, the DC voltage fed to the inverter is varied by a voltage booster. To rotate a motor at low RPM, the DC voltage is set to a relatively

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

The purpose of an inverter drive is to convert AC mains (single-phase or three-phase) into a smoothed DC (direct current) supply to operate a motor. Inverters also introduce

Get Price

All About DC Inverter Air Condtioners (2025) | Today''s

In modern heating, ventilation, and air conditioning (HVAC) units, a direct current (DC) inverter is motor control technology that gives the system

Get Price

What is a Motor Control Inverter? – Ora

A motor control inverter is an electronic device that converts direct current (DC) electrical energy into alternating current (AC) electrical energy to control the speed and torque

Get Price

Inverters and AC Drives Control, Modeling, and Simulation

Narayanaswamy P.R. Iyer Provides Simulink models for various PWM techniques used for inverters Presents vector and direct torque control of inverter-fed AC drives and fuzzy

Get Price

Three-phase inverter reference design for 200-480VAC

In-phase shunt resistor based motor current sensing is done using AMC1300B isolated amplifier and DC link voltage, IGBT module temperature sensing using the AMC1311 isolated amplifier.

Get Price

PWM Inverter Fed Induction Motor Drive:

PWM Inverter Fed Induction Motor Drive: Voltage control in the square wave inverter has been external to the inverter, by means of a phase controlled

Get Price

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

What are Inverters and AC Input Brushless DC Motors?

I know about AC speed control motors, but I''m having trouble deciding which one is better for speed control, an inverter or a brushless DC motor. Well, first of all, you need to know the

Get Price

What is an Inverter Drive and what are its features?

Inverter drives offer several advantages, including energy savings, improved process control, and reduced mechanical stress on the driven equipment. By adjusting the

Get Price

CHPATER 5

The control schemes available for the induction motor drives are the scalar control, vector or field oriented control, direct torque and flux control and adaptive control. In this chapter special

Get Price

All About DC Inverter Air Condtioners (2025) | Today''s Homeowner

In modern heating, ventilation, and air conditioning (HVAC) units, a direct current (DC) inverter is motor control technology that gives the system more control over the

Get Price

CSM_Inverter_TG_E_1_1

Omron inverters can control induction motors. Omron also provides inverters that can control synchronous motors. These motors can be controlled with Omron inverters. As induction

Get Price

Motor control and drives

Get your motor running with easy-to-implement reference designs and support tools for selecting the best-fit parts for your motor driver application.

Get Price

Converting DC to AC: Basic Principles of Inverters

This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC voltage in manufacturing.

Get Price

Power inverter

A power inverter, inverter, or invertor is a power electronic device or circuitry that changes direct current (DC) to alternating current (AC). [1] The resulting AC

Get Price

Exploring Motor Control Terms: What is an Inverter?

The main task of motor control or drive devices is to take the raw AC voltage coming from the supply source and convert it into a more stable and manageable form so that the motor can be

Get Price

VFD vs BLDC: Which Technology is Better for Speed

While AC induction motors and VFDs are often the go-to choice for speed control applications, several other alternatives are available, from servo

Get Price

AC Motor Inverters: How They Work, Principles, And Technical

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

Get Price

A Complete Guide to Inverters/Variable Frequency

The purpose of an inverter drive is to convert AC mains (single-phase or three-phase) into a smoothed DC (direct current) supply to operate a

Get Price

Mastering motor control: motor control 101

Editor''s note: This first installment in a new series on mastering motor control sets the stage for subsequent articles, introducing the basics of

Get Price

HV inverters

This allows EC-C1200-450 to work as active front end, microgrid, motor control (inverter) and as a DC-to-DC converter when combined with EC-LTS1200

Get Price

How an Inverter Drive Works and Controls the Speed of an AC

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

Motor Speed Inverters | McMaster-Carr

Choose from our selection of motor speed inverters, including enclosed AC to DC motor speed controls, AC to DC motor speed controls, and more. Same and Next Day Delivery.

Get Price

Electric Motor Inverter Explained

In this article we''ll explore how an electric motor inverter works, breaking down complex engineering principles into clear, actionable insights for automotive engineers, EV

Get Price

More related information

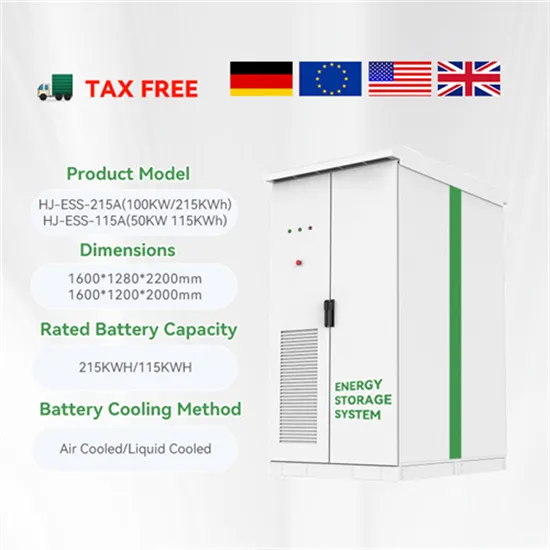

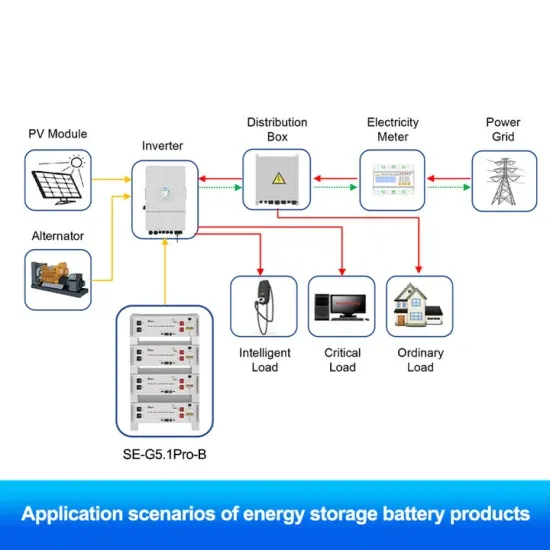

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

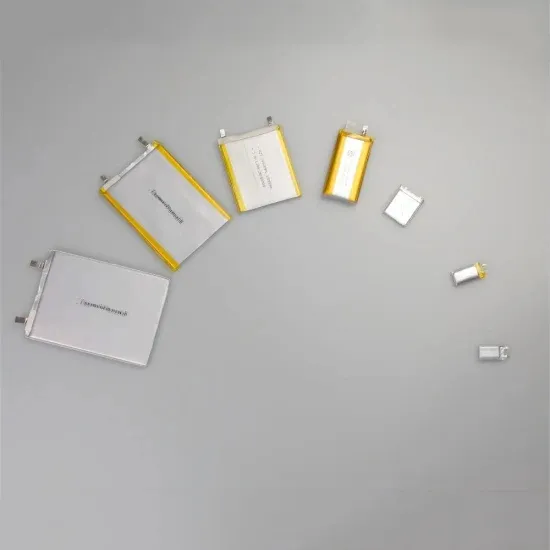

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Water pump inverter DC motor inverter

Water pump inverter DC motor inverter

How to implement an inverter for a DC motor

How to implement an inverter for a DC motor

Series DC Motor Inverter

Series DC Motor Inverter

DC unidirectional silicon controlled inverter

DC unidirectional silicon controlled inverter

DC 24V inverter

DC 24V inverter

Is the inverter DC powered

Is the inverter DC powered

Yemen DC Power Inverter

Yemen DC Power Inverter

Inverter 220 DC and AC

Inverter 220 DC and AC