Modeling and Simulation of Series DC Motors in Electric Car

The mathematical equations model of series DC motor and electronic inverter in dynamic state with reference frame d – q were considered.

Get Price

AC Motor Inverters: How They Work, Principles, And Technical

How Do Inverters Convert DC to AC Power for Motor Operation? Inverters convert direct current (DC) to alternating current (AC) power to enable motor operation through a

Get Price

A Complete Guide to Inverters/Variable Frequency

The purpose of an inverter drive is to convert AC mains (single-phase or three-phase) into a smoothed DC (direct current) supply to operate a

Get Price

SINAMICS variable frequency drives

SINAMICS variable frequency drives – the ultimate solution for all drive applications. From low voltage to direct current (DC), our drives meet your

Get Price

Chapter 17 DC to AC Inverters Switched Mode

The supply current cannot change quickly. This current is controlled by series dc supply inductance which prevents sudden changes in current. The load current magnitude is

Get Price

A Complete Guide to Inverters/Variable Frequency Drives

The purpose of an inverter drive is to convert AC mains (single-phase or three-phase) into a smoothed DC (direct current) supply to operate a motor. Inverters also introduce

Get Price

Inverter Drives | Variable Frequency Drives | RS

Single Phase Inverter: These convert a DC input into a single phase AC output. A single phase inverter can control the speed of motors or the power supply to smaller electrical systems. 3

Get Price

How an Inverter Drive Works and Controls the Speed of an AC

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Price

CHAPTER 2

2.1 Introduction The dc-ac converter, also known as the inverter, converts dc power to ac power at desired output voltage and frequency. The dc power input to the inverter is obtained from an

Get Price

Servos and Inverters

Learn more about Omron Servos and Inverters What is a frequency inverter? A frequency inverter is a device designed to control the speed of AC induction

Get Price

Inverter Drive Supermarket: Buy VSDs, Electric

The Inverter Drive Supermarket Ltd. is an Industrial Automation Distributor specialising in online sales. We supply AC Variable Speed Drives, DC

Get Price

China Variable Frequency Drive,Solar Pump Inverter

Solar water pump inverter, also known as solar variable frequency drive, converts the DC power of the solar panel into AC power, thereby driving various AC

Get Price

BLS Series Brushless DC Motors and 24 VDC Universal Driver

Oriental Motor is pleased to announce the launch of the BLS Series, designed as a simple speed control solution for users seeking better performance than traditional three

Get Price

Inverters-FREQROL | Mitsubishi Electric Automation

Inverters are variable frequency power supply units which can change the rotation speed of the three-phase induction motors easily and flexibly. High-performance and environmentally

Get Price

Products

Each Drive series is designed to meet specific application needs. Our AC Drives accurately control speed and torque, smoothly handle an increased load, and

Get Price

HV inverters

Electric converters designed for marine, off-highway and on-highway applications. A wide product portfolio to meet the needs for all kind of applications.

Get Price

What is Series Inverter? – Circuit, Working & Disadvantages

In this article, let us learn about the circuit diagram and operation of a series inverter. What is Series Inverter? A series inverter is a type of inverter in which the

Get Price

How Inverters Work

In this article we take a look at how an inverter works to convert direct current (DC) into Alternating current (AC). Inverters are used within

Get Price

How Inverters Work

In this article we take a look at how an inverter works to convert direct current (DC) into Alternating current (AC). Inverters are used within Photovoltaic arrays to provide AC

Get Price

All About DC Inverter Air Condtioners (2025) | Today''s

Below, I''ve outlined what a DC inverter is, how this power inverter works, and their advantages over traditional options so you can decide if an

Get Price

All About DC Inverter Air Condtioners (2025) | Today''s Homeowner

Below, I''ve outlined what a DC inverter is, how this power inverter works, and their advantages over traditional options so you can decide if an HVAC system with a DC inverter is

Get Price

Common Architectures and Devices for Current Source Inverter in Motor

When compared to the much more common voltage-source inverter (VSI), the current-source inverter (CSI) is rarely used for variable speed drive applications, due to its

Get Price

All About DC Inverter Air Condtioners (2025) | Today''s

In modern heating, ventilation, and air conditioning (HVAC) units, a direct current (DC) inverter is motor control technology that gives the system

Get Price

DC-AC Inverter Circuit

This document describes inverter circuits used for motor control and other applications, focusing on PWM control. It also describes the differences between two-phase and three-phase

Get Price

LEESON DRIVES #800-428-9347

Leeson SPEEDMASTER� Adjustable Speed AC & DC Drives, FHP Series AC Drives, Micro Series AC Inverters, SM Series Sub-Micro AC Inverters, SM

Get Price

Products

Each Drive series is designed to meet specific application needs. Our AC Drives accurately control speed and torque, smoothly handle an increased load, and provide numerous custom

Get Price

Inverter DC Motor Drives | Newark Electronics

Newark provides an extensive range of DC motor drives designed to deliver reliable and precise control for DC motors. Available in various power ratings and control configurations, our DC

Get Price

DC Input Brushless DC Motor Speed Control Systems

BLS Series Brushless DC Motors (BLDC Motors) - DC Input The BLS Series combines an efficient, compact, and lightweight brushless motor with a slim,

Get Price

6 FAQs about [Series DC Motor Inverter]

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

What is a DC inverter?

The IPM inverts the DC into AC - hence the term ‘Inverter’. The control method is known as ‘PWM’ for 'Pulse Width Modulation'. This means the DC is switched on and off very quickly (chopped) by the Transistor switches.

How does a DC inverter work?

The DC source provides the initial electrical power that the inverter converts into AC power. This source can come from batteries or a direct current supply. The efficiency of the inverter depends on the stability and capacity of this source. The inverter circuit is responsible for converting the direct current into alternating current.

Which type of inverter is used to control electric motors?

They are used in a number of applications both in industry and everyday life. There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical engineering. These can also be known as AC drives, variable speed drives (VSD), and variable frequency drives (VFD).

What is a series inverter?

A series inverter is a type of inverter in which the commutating components are connected in series with the load. A series inverter employs class-A commutation or resonant commutation since the current decays to zero naturally by load commutation but not by forced commutation. Class-A commutation exists in circuits supplied from a dc source only.

What is a power transistors in a small inverter drive?

The network of Power Transistors of a small Inverter drive is actually one ‘Intelligent Power Module’ (known as an IPM) and includes its own protection and basic control circuits. The IPM inverts the DC into AC - hence the term ‘Inverter’. The control method is known as ‘PWM’ for 'Pulse Width Modulation'.

More related information

Commercial & Industrial Solar Storage Market Growth

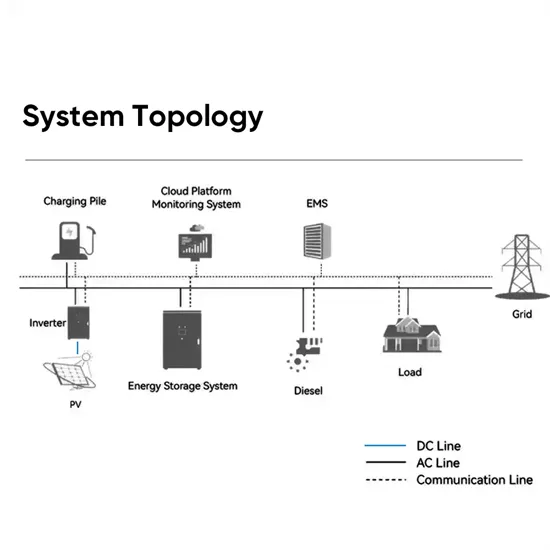

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.

Water pump inverter DC motor inverter

Water pump inverter DC motor inverter

How to implement an inverter for a DC motor

How to implement an inverter for a DC motor

DC to 220V AC inverter

DC to 220V AC inverter

How many kilowatts does a DC inverter have

How many kilowatts does a DC inverter have

Which brand of DC inverter is good

Which brand of DC inverter is good

DC plus inverter power

DC plus inverter power

Cape Verde DC inverter structure

Cape Verde DC inverter structure