Flywheel Energy Storage System: What Is It and How

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like

Get Price

Flywheel energy storage systems: A critical review on

Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical

Get Price

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· The Flywheel Of The Past Lives Again Flywheels have largely fallen off the energy storage news radar in recent years, their latter-day mechanical underpinnings eclipsed by the

Get Price

Flywheel Energy Storage System Basics

Today, flywheel energy storage systems are used for ride-through energy for a variety of demanding applications surpassing chemical batteries.

Get Price

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator. The flywheel and sometimes motor–generator may be enclosed in a vacuum chamber to reduce friction and energy loss. First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors

Get Price

Flywheel Energy Storage

Flywheel energy storage stores kinetic energy by spinning a rotor at high speeds, offering rapid energy release, enhancing grid stability, supporting renewables,

Get Price

Flywheel Energy Storage Explained

A typical flywheel energy storage system consists of several key components, including: Flywheel: The flywheel is the heart of the energy storage system, storing energy

Get Price

Flywheel Energy Storage: Alternative to Battery Storage

Flywheel energy storage systems offer a durable, efficient, and environmentally friendly alternative to batteries, particularly in applications that require rapid response times

Get Price

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get Price

How do flywheels store energy?

An easy-to-understand explanation of how flywheels can be used for energy storage, as regenerative brakes, and for smoothing the power to a

Get Price

Flywheel Energy Storage Systems and their Applications: A

Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power density and a

Get Price

Flywheel Energy Storage

Flywheel energy storage is a versatile and efficient technology that plays a crucial role in modern energy systems. Its ability to rapidly store and release energy allows it to enhance grid

Get Price

Flywheel Energy Storage

Flywheel energy storage is a versatile and efficient technology that plays a crucial role in modern energy systems. Its ability to rapidly store and release energy

Get Price

What is Thallium Flywheel Energy Storage? | NenPower

It involves a mechanical device that stores energy in the form of kinetic energy: as the rotor spins, it retains energy proportional to its speed. This technology allows for rapid

Get Price

Flywheel Energy Storage | Efficient Power Solutions

Flywheels can store rotational energy efficiently and respond rapidly when needed, making it the perfect short-term energy storage solution.

Get Price

Flywheel Energy Storage Basics

The high energy density and low maintenance requirements make it an attractive energy storage option for spacecraft. Conclusion: Flywheel energy storage is

Get Price

Flywheel Energy Storage

Flywheel energy storage, an innovative mechanical energy storage method, will hold a significant position in the future energy storage field.

Get Price

What is a Flywheel Storage System? High-Speed Energy Backup

Conclusion Flywheel storage systems represent a high-speed, efficient, and environmentally friendly energy storage solution. Their unique characteristics make them well

Get Price

What is a flywheel?

What is a flywheel? Explore this kinetic energy storage solution for peak shaving. Ideal for sustainable and efficient energy management.

Get Price

Flywheel Energy Storage: A High-Efficiency Solution

By storing kinetic energy as the flywheel spins, energy can be rapidly discharged when needed. The robust design, reinforced by high

Get Price

Energy Storage Flywheels and Battery Systems

Piller is a market leader of kinetic energy storage ranging up to 60MJ+ per unit. The Piller POWERBRIDGE™ storage systems have unique design techniques employed to provide high

Get Price

A review of flywheel energy storage systems: state of the art and

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get Price

Flywheel Energy Storage (FES) Systems

Explore the intriguing world of Flywheel Energy Storage (FES) systems, their working principles, benefits, applications, and future prospects.

Get Price

Flywheel Energy Storage: A High-Efficiency Solution

By storing kinetic energy as the flywheel spins, energy can be rapidly discharged when needed. The robust design, reinforced by high-strength materials, ensures durability

Get Price

billyprim

Flywheel Energy Storage Systems (FESS) work by storing energy in the form of kinetic energy within a rotating mass, known as a flywheel. Here''''s the working principle explained in simple

Get Price

WHAT IS A FLYWHEEL ENERGY STORAGE UNIT?

The novel portable energy storage technology, which carries energy using hydrogen, is an innovative energy storage strategy because it can store twice as much energy at the same 2.9

Get Price

Flywheel Energy Storage System: What Is It and How Does It

In a flywheel energy storage system, electrical energy is used to spin a flywheel at incredibly high speeds. The flywheel, made of durable materials like composite carbon fiber, stores energy in

Get Price

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get Price

6 FAQs about [What is Thallium Flywheel Energy Storage]

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

What is flywheel technology?

We will explore its advantages, applications across various industries, and a comparative analysis with other storage methods. Flywheel technology is a sophisticated energy storage system that uses a spinning wheel to store mechanical energy as rotational energy. This system ensures high energy output and efficient recovery.

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

How does a flywheel retain energy?

Energy Storage: The flywheel continues to spin at high speed, maintaining energy as long as friction and resistance are minimized. The longer it spins, the more energy it holds, similar to how the skater retains rotational energy as they keep spinning.

How does Flywheel energy storage impact the energy sector?

The Impact of Flywheel Energy Storage on the Energy Sector Flywheel energy storage offers numerous advantages, making it a vital technology in the energy sector. One of its primary benefits is efficiency; flywheels can recover up to 80% of the stored energy, ensuring minimal losses during the conversion process.

More related information

-

What wind power can be used for flywheel energy storage

What wind power can be used for flywheel energy storage

-

What are the flywheel energy storage power stations in the United States

What are the flywheel energy storage power stations in the United States

-

What is the small flywheel energy storage like

What is the small flywheel energy storage like

-

The role of flywheel energy storage power station

The role of flywheel energy storage power station

-

Burundi flywheel energy storage equipment

Burundi flywheel energy storage equipment

-

Guatemala also uses flywheel energy storage

Guatemala also uses flywheel energy storage

-

What brands of photovoltaic container energy storage power stations are there

What brands of photovoltaic container energy storage power stations are there

-

How much does flywheel energy storage wind power cost

How much does flywheel energy storage wind power cost

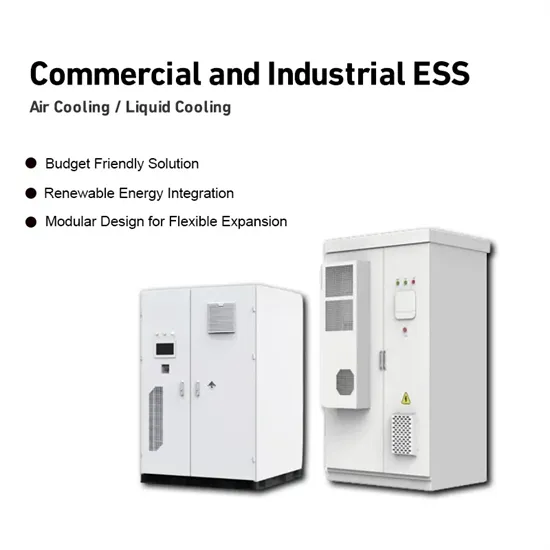

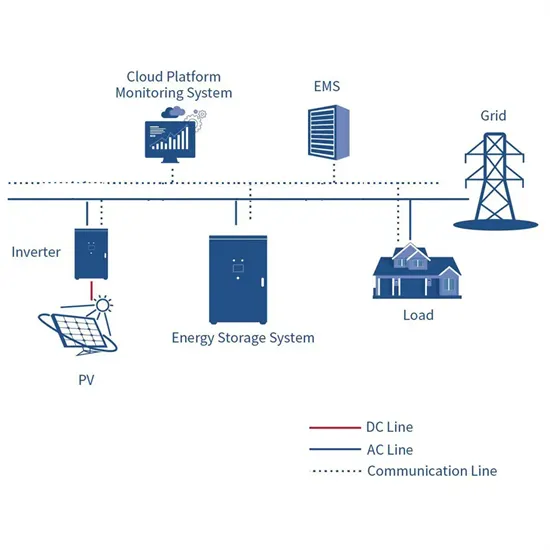

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.