Power Storage Battery Cabinet Voltage: The Backbone of

Voltage in battery storage cabinets isn''t just about keeping the lights on – it''s the difference between smooth operations and catastrophic meltdowns. A 2023 study revealed that 68% of

Get Price

Lithium Server Rack Battery System

What is Server Rack Battery? Server rack battery is a backup power supply that is specifically designed to be installed in a server rack. It provides uninterrupted power to servers and other

Get Price

Stationary UPS Sizing Calculations – Part Seven

electrical engineering including electrical design courses, electrical calculations, electrical worksheets, electrical programs and electrical books

Get Price

STATIC UNINTERRUPTIBLE POWER SUPPLIES

The third part of the classification code defines the dynamic performance of the output voltage under load variations in three different categories: • variation of the operating modes (routine

Get Price

How many V does the energy storage battery cabinet have?

Energy storage battery cabinets act as centralized hubs for managing electrical energy, functioning as reservoirs that store energy for later use. A critical aspect of these

Get Price

Stationary UPS Sizing Calculations – Part Six

For optimal battery performance, the battery room temperature should be maintained at a constant 77°F. Temperatures below 77°F increase the battery''s life but decrease its

Get Price

Data center batteries

Calculate the charging voltage based on the battery parameters, and measure the data center batteries output charging voltage, which meets the charging requirements of this

Get Price

The Not-So-Shocking Truths About UPS Safety

Measure and record input AC voltages and currents on all three phases. Measure and record delta voltage at the static switch. Measure and record rectifier output DC voltage and adjust if

Get Price

How many V does the energy storage battery cabinet

Energy storage battery cabinets act as centralized hubs for managing electrical energy, functioning as reservoirs that store energy for

Get Price

DC power supply cabinet working principle and role

The information detected by the temperature detection module, the single battery voltage detection module and the current and voltage output

Get Price

How to do UPS Battery Wiring?

F. Before connecting the battery cables from the battery cabinet to the host, measure the battery voltage with a multimeter, which should be 103.36V, and

Get Price

Eaton 9390 Integrated Battery Cabinet (Models IBC-S and

The Integrated Battery Cabinet (IBC) systems are housed in single free‐standing cabinets. Two models are available: Model IBC-S (small cabinet) and Model IBC-L (large cabinet). Each

Get Price

Stationary UPS Sizing Calculations – Part Six

For optimal battery performance, the battery room temperature should be maintained at a constant 77°F. Temperatures below 77°F increase the

Get Price

How to design an energy storage cabinet: integration and

Data collection and analysis: Collect the working data of energy storage cabinets (such as battery voltage, current, temperature, etc.) in real time, and optimize the energy

Get Price

UPS Systems | UPS and Power Conditioning | ABB

ABB has the UPS technology for every need. Protection against all power failures, voltage regulation, power factor correction and harmonics is guaranteed.

Get Price

755-00086 R02 BC16 MITSUBISHI MANUAL

Review the supplied cabinet drawing for information on the battery cabinet output. All cables should be sized per NEC and any other local codes pertaining to this equipment.

Get Price

What is the voltage of the energy storage battery cabinet?

The voltage of energy storage battery cabinets typically ranges from 12V to 800V, influenced by application requirements, technology used, and the configuration of battery cells.

Get Price

General Technical Specification for Uninterruptible Power

viii) ix) x) Overload Overload shutdown Equipment over-temperature Battery circuit breaker open Battery discharging Low battery voltage Input power failure Inverter output over-voltage /

Get Price

Powerware 9390 Integrated Battery Cabinet (Models IBC-S

During brownouts, blackouts, and other power interruptions, battery cabinets provide emergency DC power to the UPS to safeguard operation of the critical load. The Integrated Battery

Get Price

Battery Room Ventilation and Safety

BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms must be adequately

Get Price

Mitsubishi Electric Power Products, Inc. BC7 Battery Cabinet

Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get Price

What is the output voltage of the energy storage cabinet?

The output voltage of the energy storage cabinet is determined by various factors, including the design architecture, battery configuration, and specific application purpose.

Get Price

UBC87 Battery Cabinet Installation, Operation,

Install the main POS and NEG cables from the output circuit breaker to the correct battery posts on the designated battery units shown in the provided battery system schematic.

Get Price

Open_Compute_Project_Battery_Cabinet_v1.0

The battery cabinet cannot withstand the load after the AC outage, resulting in a dramatic voltage drop during the first few seconds. This case is typical when one or more battery strings are

Get Price

How to calculate the battery cabinet in the computer room

This document describes how to estimate heat output from information technology (IT) equipment and other devices in a data center such as UPS, for purposes of Today, we will explain the

Get Price

6 FAQs about [Output voltage of battery cabinet in computer room]

How do you calculate the ventilation requirements of a battery room?

The following method may be used to calculate the ventilation requirements of a battery room. 26.8Ah input to a fully charged cell will liberate 8 g of oxygen and 1 g of hydrogen. One (1) g of hydrogen occupies a volume of 12 liters at 20°C and at a pressure of one standard atmosphere. Therefore 26.8Ah input will evolve 12 liters of hydrogen.

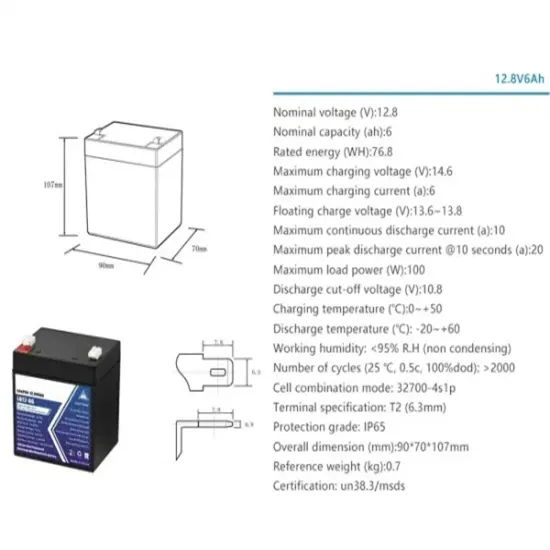

What should be considered when charging a data center battery?

⑤ For high-voltage DC, the server input overvoltage protection issue (282V) must be considered when equalizing charging. ● The charging capacity of the data center batteries is generally not less than 1.2 times the discharged capacity. When the charging current does not decrease for 3 consecutive hours, the charging is considered to be terminated.

How to maintain a data center battery?

Maintenance points for data center batteries ● Insulating pads should be arranged in the battery pack maintenance channel. ● Batteries from different manufacturers, different capacities, and different models are strictly prohibited from being used in the same system.

How should a battery room be designed?

Battery rooms shall be designed with an adequate exhaust system which provides for continuous ventilation of the battery room to prohibit the build-up of potentially explosive hydrogen gas. During normal operations, off gassing of the batteries is relatively small.

Which batteries are used in data center ups power supply?

Currently, the batteries configured in data center UPS power supply are mainly valve-regulated sealed lead-acid batteries (VRLA). However, with the development and improvement of battery technology, lithium batteries have gradually become one of the choices in the future.

How do you label a data center battery?

Label the numbers for data center batteries in sequence. Use an internal resistance meter to measure the internal resistance and data center batteries voltage, and record the measurement data of each battery according to the label number.

More related information

-

The role of battery cabinet in communication high voltage distribution room

The role of battery cabinet in communication high voltage distribution room

-

Battery cabinet in low voltage distribution room

Battery cabinet in low voltage distribution room

-

How much power does the battery cabinet output

How much power does the battery cabinet output

-

Voltage stabilized power supply battery cabinet installation

Voltage stabilized power supply battery cabinet installation

-

How to view the output current of the battery cabinet

How to view the output current of the battery cabinet

-

Indoor integrated cabinet in the flow battery room of a communication base station

Indoor integrated cabinet in the flow battery room of a communication base station

-

Battery cabinet in the fire control room

Battery cabinet in the fire control room

-

Battery output voltage range for communication base stations

Battery output voltage range for communication base stations

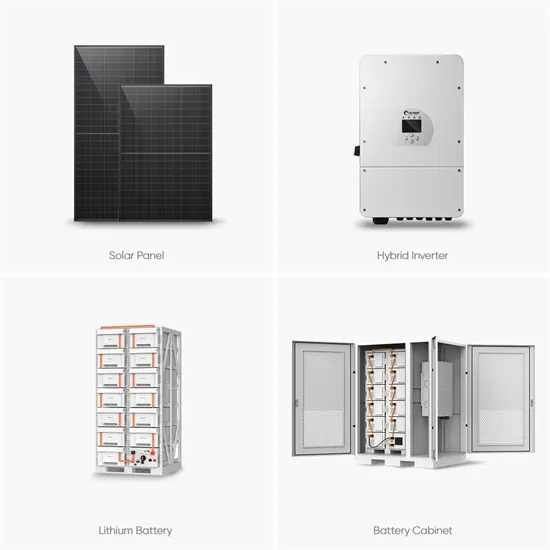

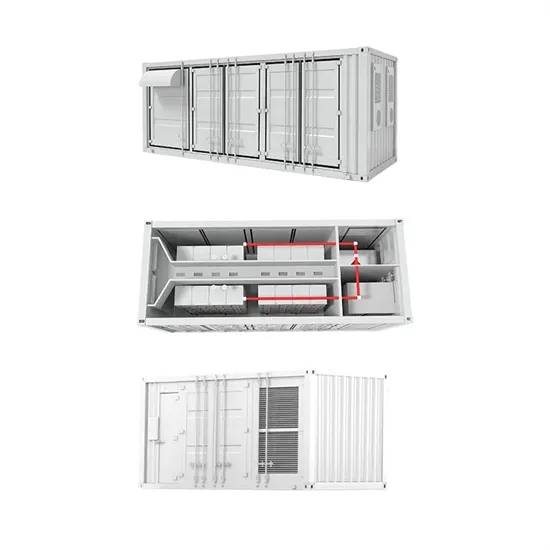

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.