How to Assemble a Lithium Battery Pack Lithium Battery Assembly

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get Price

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

In this article, we will have an in-depth discussion on how to build a lithium ion battery pack? We will provide a step by step guide that we hope will help you understand the

Get Price

The Ultimate Guide For Lithium-Ion Battery Packs

Key Takeaway: Lithium-ion battery packs are complex assemblies that include cells, a battery management system (BMS), passive components, an

Get Price

How to Assemble a Lithium Battery Pack Lithium Battery

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get Price

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get Price

Beginner-Friendly Tips for Assembling Lithium Battery Packs

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

Battery Factory How to Build the Lithium-Ion Battery Pack?

Nowadays, the meaning of essential battery packs is the second one. A lithium-ion battery pack mainly combines battery cells, battery PCB, battery connecting sheets, label

Get Price

How to Build a Lithium Ion Battery Pack? A Step by

Lithium-ion (Li-ion) batteries have become a primary power source for a various applications, from consumer electronics, electric vehicles, power

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get Price

Design for Assembly and Disassembly of Battery Packs

Based on the evaluation, an "ideal" battery is developed with focus on the hardware, hence the housing, attachment of modules and wires, thermal system and battery management box. An

Get Price

The EV Battery Manufacturing Process: Step by Step

The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Get Price

How Are Lithium Battery Packs Assembled?

Lithium battery pack assembly is a complex process that involves several steps, from cell selection and testing to final assembly and quality control. The process requires specialized

Get Price

(Infographics #3) Battery Making at a Glance

(Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Get Price

An Exhaustive Guide To Building 18650 Packs

Fortunately [Adam Bender] is on hand with an extremely comprehensive two-part guide to designing and building lithium-ion battery

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

Lithium-ion batteries are usually produced using two lithium-ion battery assembly process methods: manual assembly and automated assembly. Manual assembly is the most

Get Price

Energizer Ultimate Lithium Battery AA and AAA

About this item This bundle includes: (1) 4 pack of Energizer Ultimate Lithium AA Batteries and (1) 4 Pack of Energizer Lithium AAA

Get Price

Battery Factory How to Build the Lithium-Ion Battery

Nowadays, the meaning of essential battery packs is the second one. A lithium-ion battery pack mainly combines battery cells, battery PCB,

Get Price

How to Make a Rechargeable 12V Battery Pack

Learn how to make a rechargeable 12V battery pack for various uses. A complete guide with tips, tools, and step-by-step instructions.

Get Price

Lithium Battery Packs | BigBattery | Your Source for Power

"Big Battery made converting our 48v lead acid EZGO cart to lithium a breeze. Our cart is lighter, faster and the range went up dramatically using just a single Falcon Elite battery.

Get Price

Lithium-ion cell and battery production processes

In contrast to module and pack assembly, the production of lithium-ion battery cells typically integrates various production technologies and draws on wide-ranging fields of

Get Price

Automatic Battery PACK Assembly Line for lithium-ion prismatic

Official Site: Mail:info@huiyaolaser --Sale Director Tiffany YaoLaser-Prismatic Battery Module PACK assembly line Part One,efficiency of the production line is 12

Get Price

How to Build Your Own Battery Pack

Building your own battery pack is a rewarding project that allows you to create a customized power source for various devices, from electric vehicles to solar setups. Whether

Get Price

Beginner-Friendly Tips for Assembling Lithium Battery

Learn how to assemble a lithium battery pack with beginner-friendly tips on design, safety, and tools for optimal performance and reliability.

Get Price

How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get Price

Adhesive Tape Solutions for the Lithium Battery Industry

Used for high-temperature fixation and bonding of lithium battery casings, as well as for insulation protection of internal electrodes and external tabs of battery cells. 【2】Termination tape

Get Price

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Get Price

An Exhaustive Guide To Building 18650 Packs

Fortunately [Adam Bender] is on hand with an extremely comprehensive two-part guide to designing and building lithium-ion battery packs from cylindrical 18650 cells. (Edit

Get Price

6 FAQs about [Lithium battery assembly double pack]

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

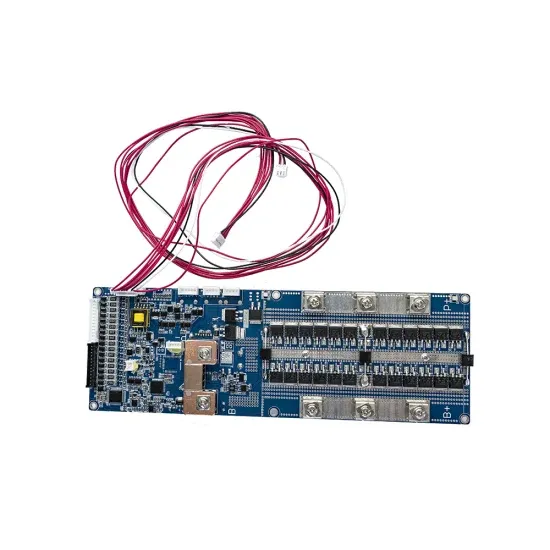

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

How a lithium ion battery is made?

The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries. The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

More related information

-

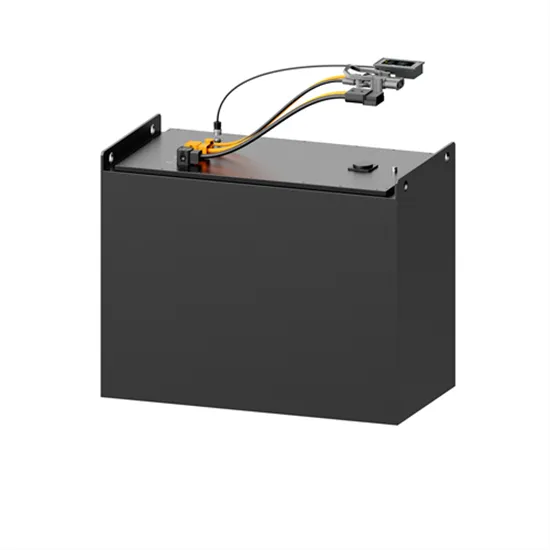

Large-cell lithium battery pack assembly

Large-cell lithium battery pack assembly

-

Lithium battery pack design and assembly

Lithium battery pack design and assembly

-

What does the lithium battery pack assembly include

What does the lithium battery pack assembly include

-

Lithium battery pack assembly equipment

Lithium battery pack assembly equipment

-

12v lithium battery pack mobile power supply

12v lithium battery pack mobile power supply

-

Bahamas lithium battery pack customization

Bahamas lithium battery pack customization

-

Lithium battery pack operating voltage

Lithium battery pack operating voltage

-

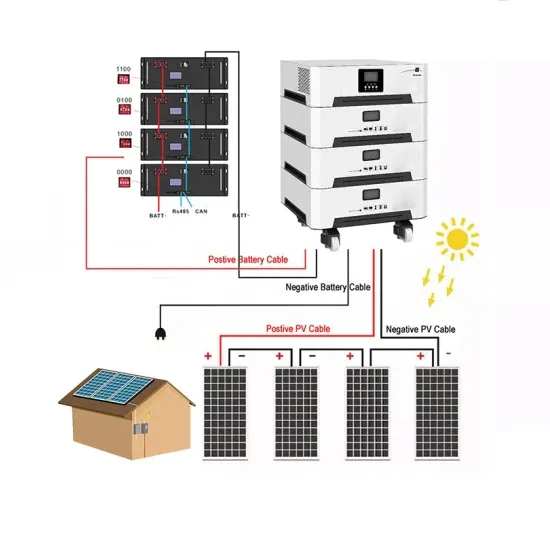

Lithium battery pack for energy storage

Lithium battery pack for energy storage

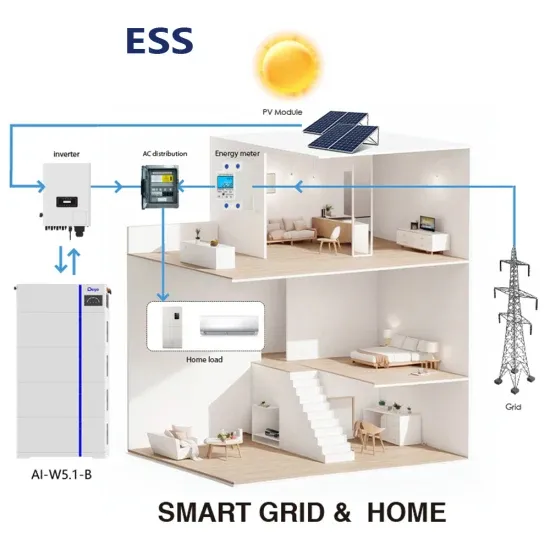

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.