(PDF) Lithium-ion Battery Cell Production Process

Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Get Price

Aging mechanisms, prognostics and management for lithium-ion batteries

In the rapidly evolving landscape of energy storage, lithium-ion batteries stand at the forefront, powering a vast array of devices from mobile phones to electric vehicles and

Get Price

Understanding Battery Pack Technology: Key Components, Production

As demand for high-performance battery solutions grows, innovations continue to emerge in battery pack technologies. Solid-state batteries, offering higher energy density and

Get Price

Battery Pack Manufacturing Process: Step-by-Step

In this article, we explore the final step in battery production – the battery pack process. This critical phase brings together individual battery

Get Price

Mastering the Battery Pack Assembly Process: A

The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery packs used

Get Price

Mastering the Battery Pack Assembly Process: A Comprehensive

The battery pack assembly process is a cornerstone of modern manufacturing, essential for producing high-performance battery packs used in electric vehicles (EVs),

Get Price

Challenges and opportunities for high-quality battery production at

We first describe the interplay between various battery failure modes and their numerous root causes. We then discuss how to manage and improve battery quality during

Get Price

Does Battery Charge Change Weight

Yes, a battery''s charge does change its weight—but the difference is incredibly small. This counterintuitive fact stems from Einstein''s famous equation, E=mc². Most assume

Get Price

The relationship between battery production and manufacturing

Why is battery manufacturing important? As batteries are core components in many industrial and consumer sectors, enhancing manufacturing efficiency directly contributes to sustainable

Get Price

Battery Pack Manufacturing Process

Understanding how battery packs are manufactured is crucial as industries demand higher performance and sustainability. From raw material selection to final assembly,

Get Price

Review on state-of-health of lithium-ion batteries:

State-of-health (SOH) monitoring of lithium-ion batteries plays a key role in the reliable and safe operation of battery systems. Influenced by multip

Get Price

Understanding Battery Pack Technology: Key Components,

As demand for high-performance battery solutions grows, innovations continue to emerge in battery pack technologies. Solid-state batteries, offering higher energy density and

Get Price

Challenges and opportunities for high-quality battery

As the world electrifies, global battery production is expected to surge. However, batteries are both difcult to produce at the gigawatt-hour scale and fi sensitive to minor manufacturing

Get Price

Lithium-ion Battery Pack Manufacturing Process & Design

At the heart of the battery industry lies an essential lithium-ion battery assembly process called battery pack production.

Get Price

Electric battery

An electric battery is a source of electric power consisting of one or more electrochemical cells with external connections [1] for powering electrical

Get Price

Battery Pack Manufacturing Process: Step-by-Step Guide

In this article, we explore the final step in battery production – the battery pack process. This critical phase brings together individual battery cells, combines them into

Get Price

What Happens To All Of The Old EV Batteries?

10 hours ago· The old lead & acid batteries are being phased out fast, and lithium-ion batteries are taking their place. The new batteries are made using either carbon or graphite, a metal

Get Price

Designing a Battery Pack?

Designing a battery pack ? One Place to Learn about batteries for electric vehicles: Cell Chemistry, benchmarking, Algorithms, Manufacturing.

Get Price

Review of Lithium as a Strategic Resource for Electric

This article presents a comprehensive review of lithium as a strategic resource, specifically in the production of batteries for electric

Get Price

Understanding the Relationship Between Lithium-ion Cells and

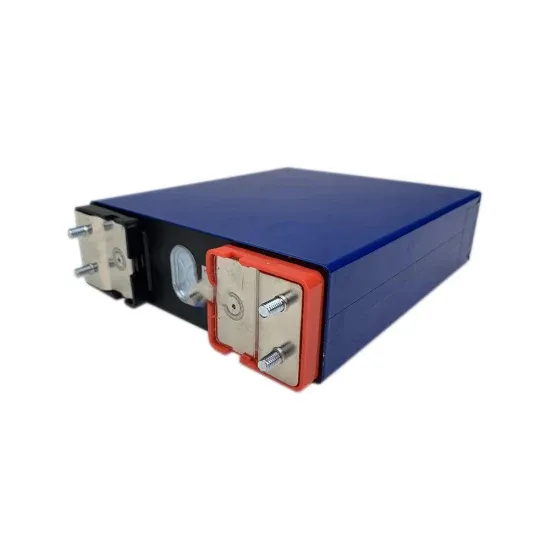

Definition: A lithium-ion cell is the basic unit storing electrical energy, while a battery pack combines multiple cells in series/parallel configurations to achieve desired voltage,

Get Price

Battery Research Efforts | Center for Advanced Life

More than 25 years after their commercialization, lithium-ion batteries still continue to pose reliability and safety challenges. While the research has

Get Price

The Future of Energy Storage: Five Key Insights on Battery

Breakthroughs in battery technology are transforming the global energy landscape, fueling the transition to clean energy and reshaping industries from transportation to utilities.

Get Price

Battery Cells, Modules, and Packs: Key Differences Explained

Learn the differences between battery cells, modules, and packs, and how they work together to power applications efficiently.

Get Price

Understanding the Relationship Between Lithium-ion Cells and Battery

Definition: A lithium-ion cell is the basic unit storing electrical energy, while a battery pack combines multiple cells in series/parallel configurations to achieve desired voltage,

Get Price

Perspective: Challenges and opportunities for high-quality

Abstract As the impacts of climate change become increasingly apparent, the need for widespread electrification is now internationally recognized. As a result, global battery

Get Price

Sustainable manufacturing practices for EV battery packs:

As EV adoption keeps to upward push, the demand for green and sustainable battery technology is becoming greater urgent. EV battery packs, typically composed of lithium

Get Price

6 FAQs about [The relationship between pack batteries and battery production]

What makes a successful battery pack manufacturing process?

Effective cell selection and procurement lay the groundwork for successful battery pack manufacturing, directly impacting the quality and performance of the final product. The battery cell manufacturing process is a complex, multi-step procedure that ensures the efficiency, safety, and longevity of battery packs.

How does a battery pack work?

The journey towards a fully functional battery pack continues as multiple modules are assembled into a cohesive unit. The component assembly process involves interconnecting these modules, ensuring they work harmoniously to provide the desired power output.

What is battery pack production?

In conclusion, Battery pack production is a complex and multifaceted process that requires meticulous attention to detail, strict quality control, and a commitment to safety.

What is a battery pack assembly process?

The battery pack assembly process is a meticulously planned sequence of steps that transforms individual components into a fully functional battery pack. It begins with the procurement of high-quality materials, including battery cells, BMS, wiring, and protective casings.

What is battery pack technology?

This integrated system powers everything from electric vehicles to renewable energy storage, making battery pack technology crucial for modern energy solutions. 1. **Battery Cells** Battery cells are the heart of the pack, responsible for storing and releasing energy. Lithium-ion cells and nickel-metal hydride cells are among the most common types.

Why is battery pack assembly important?

The significance of the battery pack assembly process lies in its direct impact on the performance and safety of the final product. A well-assembled battery pack ensures optimal energy storage, efficient power delivery, and long-term durability.

More related information

-

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallel batteries

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallel batteries

-

Lithium battery pack production in Western Europe

Lithium battery pack production in Western Europe

-

Pack battery production safety precautions

Pack battery production safety precautions

-

Lifespan of high temperature lithium battery pack

Lifespan of high temperature lithium battery pack

-

Croatia lithium battery pack supplier company

Croatia lithium battery pack supplier company

-

West Africa pack lithium battery equipment

West Africa pack lithium battery equipment

-

Mozambique new energy lithium battery pack

Mozambique new energy lithium battery pack

-

Papua New Guinea 24v lithium battery pack

Papua New Guinea 24v lithium battery pack

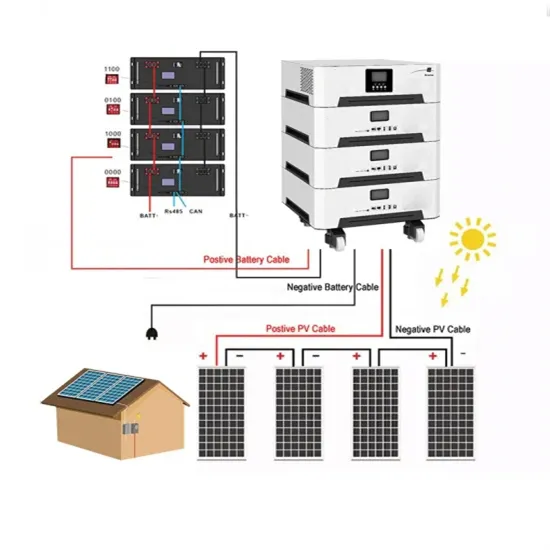

Commercial & Industrial Solar Storage Market Growth

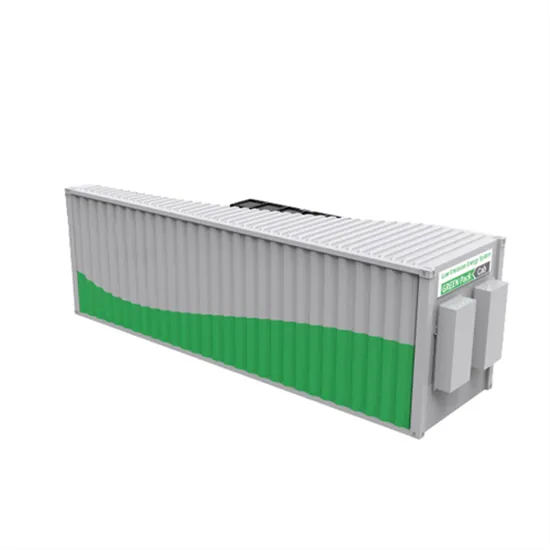

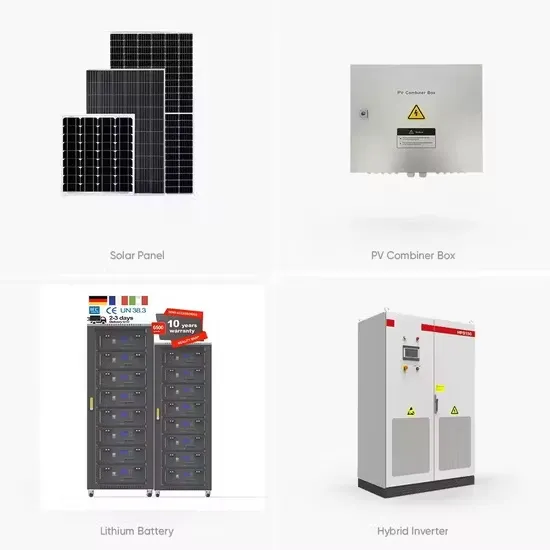

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.