EV Battery Manufacturing Safety: Top Five Insights and Best

Electric vehicle (EV) battery manufacturing is a rapidly growing sector with unique safety challenges, from chemical handling to explosion risks and stringent regulatory compliance

Get Price

A Detailed Guide on Safety and Security of Battery Pack

In accordance with quality control procedures, the battery packs should be inspected at various stages of production and the proper design verified. During and after fabrication, battery cells

Get Price

Industrial_Battery_Catalog (Lithium, Nickel-metal-hydride,

Safety Precautions and Usage Guidance Some batteries contain flammable substance which, if misused or mishandled, may result in electrolyte leakage, deformation, heat-generation,

Get Price

ENSURING WORKER SAFETY IN ELECTRIC VEHICLE

Electric vehicle manufacturers and other sector members including lithium-ion cell and battery pack producers are increasingly subject to safety requirements specific to the goods they

Get Price

Battery module production precautions

The battery PACK module production line refers to the production process of combining multiple single cells into a battery pack through series and parallel connections. The PACK module is a

Get Price

Lithium-Ion Battery Safety

Lithium-ion batteries are found in the devices we use everyday, from cellphones and laptops to e-bikes and electric cars. Get safety tips to help prevent fires.

Get Price

What Safety Precautions Are Required When Working with

When working with batteries, it''s essential to follow safety precautions to prevent accidents and injuries. Key precautions include using personal protective equipment (PPE),

Get Price

Lithium Ion Battery Pack Handling Precautions

The battery pack is equipped with built-in safety/protection features. Should these features be disabled, the battery pack can leak acid, overheat, emit smoke, burst and/or ignite.

Get Price

Guide to Battery Safety Standards in India – compiled

These amendments include additional safety requirements related to battery cells, BMS, on-board charger, design of battery pack, thermal

Get Price

Custom Lithium Battery Pack Manufacturing

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves

Get Price

Vehicle Battery Safety Roadmap Guidance

As this safety approach applies to vehicle batteries, thermal stability is perhaps the most important of several parameters that determine safety of Li-ion cells, modules, and battery packs.

Get Price

Connection methods and precautions of Pack battery packs

Pack battery packs are a common form of battery assembly in fields such as industrial equipment and energy storage systems. The connection method directly affects the performance, safety

Get Price

What Keeps Lithium-Ion Batteries Safe?

Keep safe! These are just some of the many safety features integrated into authentic, safety-tested lithium-ion cells and batteries. Fitting cells into a compact battery takes a lot of expertise

Get Price

Battery Safety Series: How to Keep EV Batteries Safe

In this edition of our Battery Safety series, we will focus on the safety considerations concerning a single battery pack assembly. The first safety

Get Price

Battery Safety Series: How to Keep EV Batteries Safe at the Pack

In this edition of our Battery Safety series, we will focus on the safety considerations concerning a single battery pack assembly. The first safety consideration is structural integrity, as the whole

Get Price

10 Essential Safety Rules For Lithium Battery Pack Design

To help engineers and development teams enhance the intrinsic safety of lithium battery packs, we''ve summarized 10 essential safety rules based on industry best practices.

Get Price

Sep

Course Outcome: Candidate can understand the technology from basic of EV to EVSE equipment like Lithium-ion battery, Battery pack assembly process, EV Motor, Charger, charging station

Get Price

Battery Charging, Storage, and Handling Safety Tips

Safety precautions and OSHA standards pertaining to battery charging, handling, and storage in the workplace or on the job site.

Get Price

Battery Handling Safety: Essential Practices | HSENation

Battery Handling Safety: Toolbox Talk Introduction: Batteries power a wide range of equipment in our daily work environments, from vehicles to

Get Price

Safety Precautions for Battery Packs

Explore PHYLION''s reliable and safe Battery Pack solutions, designed for performance, durability, and safety in every environment.

Get Price

Lithium-ion Battery Safety

Lithium-ion batteries may present several health and safety hazards during manufacturing, use, emergency response, disposal, and recycling.

Get Price

Safety for Battery Production

During the production and assembly of battery cells, hazards such as fire and explosions or hazardous substances must be kept under control. Accidents and downtime must be avoided.

Get Price

Lithium Battery Safety Procedure

In accordance with quality control procedures, the battery packs should be inspected at various stages of production and the proper design verified. During and after fabrication, battery cells

Get Price

A Detailed Guide on Safety and Security of Battery Pack

An in-depth guide to ensure the safety and security of the battery pack. Find out the potential hazards that can be detrimental to the battery''s life cycle.

Get Price

Lithium Batteries: Safety, Handling, and Storage

Electronics technicians (ETs) will follow safety procedures when assembling battery packs and handling batteries. The waste technician will review documents and follow departmental

Get Price

6 FAQs about [Pack battery production safety precautions]

What are the safety considerations regarding a single battery pack assembly?

In this edition of our Battery Safety series, we will focus on the safety considerations concerning a single battery pack assembly. The first safety consideration is structural integrity, as the whole pack constitutes a significant mass.

What makes a battery pack Safe?

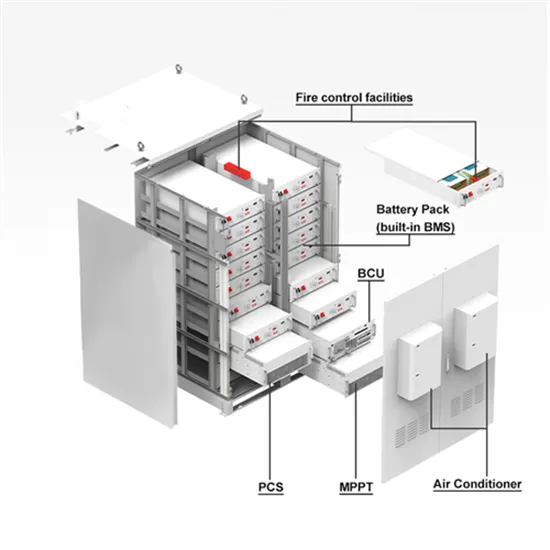

The design for the safety of the whole pack is an integration of all the subsystems into one single unit. Mechanical design, high- and low-voltage electrical design, sensors, pumps, valves, and all the elements of thermal management together, form the basis of the whole battery pack design and development.

Are lithium-ion batteries safe?

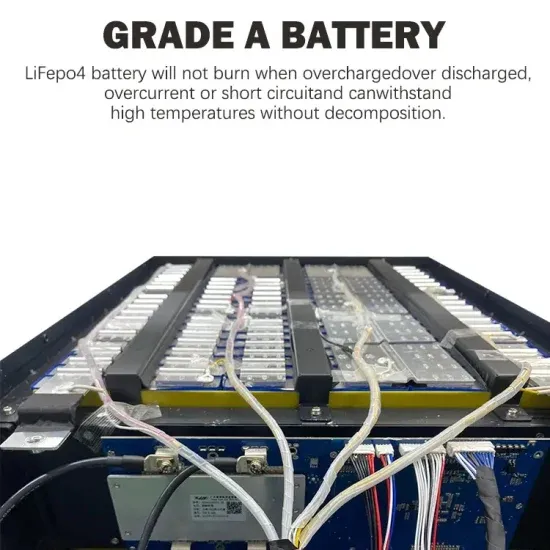

The lithium-ion battery is one of the most vulnerable battery types in the sense that any voltage, current, temperature, or short circuit fluctuation can lead to a catastrophe. The most viable way to enforce the safety and security of battery packs is via integration with the battery management system.

Can You Store batteries on the floor?

Do not store batteries on the floor, particularly on the research vessels where they may encounter seawater. ETs or Instrument Technicians may occasionally be assembling battery packs or manufacturing battery packs from cells. It is important to follow safety precautions when selecting and soldering batteries into assemblies.

How important is a battery pack?

The first safety consideration is structural integrity, as the whole pack constitutes a significant mass. The strength and stiffness are unquestionably important as the mass influences the way the battery pack structurally behaves, both separate from the vehicle and when installed in the vehicle.

What is a battery pack assembly?

A battery pack, comprised of a collection of modules enclosed together, forms a crucial component within electric vehicles (EVs). It is often a large assembly integrated into the vehicle’s structure. In this edition of our Battery Safety series, we will focus on the safety considerations concerning a single battery pack assembly.

More related information

-

Lithium battery pack production in Western Europe

Lithium battery pack production in Western Europe

-

Pack lithium battery production equipment

Pack lithium battery production equipment

-

Vertical lithium battery pack production

Vertical lithium battery pack production

-

The relationship between pack batteries and battery production

The relationship between pack batteries and battery production

-

Rwanda lithium iron phosphate battery pack

Rwanda lithium iron phosphate battery pack

-

Lithium battery pack ampere and volt

Lithium battery pack ampere and volt

-

Croatia lithium battery pack supplier company

Croatia lithium battery pack supplier company

-

Togo lithium battery pack wholesale

Togo lithium battery pack wholesale

Commercial & Industrial Solar Storage Market Growth

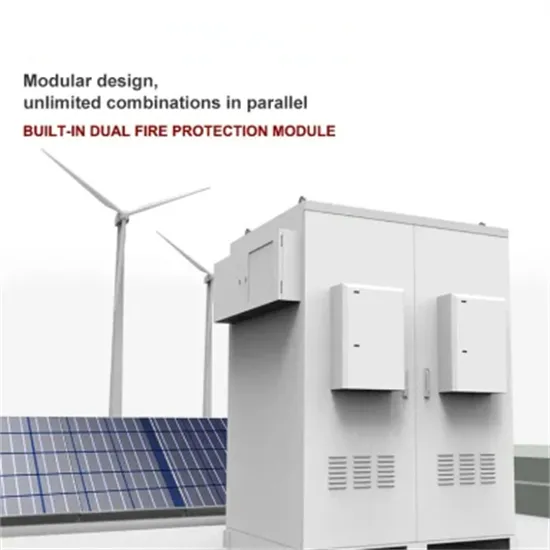

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.