Work Space about battery racks | Information by Electrical

Working space about the battery systems shall comply with 110.26. Working clearance shall be measured from the edge of the battery rack. Working space is only required

Get Price

Safety Clearance Recommendations for Electrical Panel

One Entrance at each end of the equipment. Get access to premium HV/MV/LV technical articles, electrical engineering guides, research

Get Price

1926.441

Batteries of the unsealed type shall be located in enclosures with outside vents or in well ventilated rooms and shall be arranged so as to prevent the escape of fumes, gases, or

Get Price

The Optimal Distance Between Wall And Base Kitchen Cabinet:

This comprehensive guide provides all the information you need to know about the ideal distance between a wall and a base kitchen cabinet. Discover the optimal measurements and factors to

Get Price

Requirements for the Design of ICT rooms

When fitting out ICT rooms it is important to be actively involved in the design of the rooms in terms of width/depth/height, raised floors, location of equipment racks and room cooling units

Get Price

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get Price

Ideal Kitchen Layout: Island-To-Cabinets Spacing | ShunShelter

The standard distance between kitchen islands and surrounding cabinets or walls is between 36 and 48 inches. This distance provides ample room for movement and

Get Price

Battery Cabinets vs. Battery Racks

Because air exchanges in most computer rooms far exceed the ventilation of a normal work environment, placement of battery cabinets in a

Get Price

How Much Space Should You Leave Between Your Desk And Wall?

The distance between your desk and wall can affect your productivity, workflow, and even your posture. In this article, we''ll guide you through the process of determining the ideal

Get Price

The Optimal Distance Between Kitchen Cabinets And Walls: How

When planning your kitchen layout, it''s important to consider the distance between your kitchen cabinets and walls. This article discusses the optimal distance and how close they should be

Get Price

Battery Cabinets vs. Battery Racks

Because air exchanges in most computer rooms far exceed the ventilation of a normal work environment, placement of battery cabinets in a computer room is rarely a problem.

Get Price

How to Calculate Heat Loads and Server Room

An article on how to calculate the heat loads and cooling requirements for datacenters, computer, server rooms and IT closet air

Get Price

Do Lithium Ion Batteries Require A Battery Room? Storage

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get Price

Safe Clearances for Electrical Equipment: Working

The aisle (s) between pieces of such equipment, with live parts on both sides of the aisle, must be at least 4 feet wide. If the voltage exceeds

Get Price

Safe Clearances for Electrical Equipment: Working Space and

The aisle (s) between pieces of such equipment, with live parts on both sides of the aisle, must be at least 4 feet wide. If the voltage exceeds 600, clearance must be increased even further.

Get Price

Space Planning: Kitchen Cabinet Spacing For A

Space between upper and lower cabinets: 18 inches is recommended When it comes to the space between upper and lower kitchen

Get Price

Safety Requirements for Batteries and Battery Rooms

Safety Safety Requirements for Batteries and Battery Rooms Do you know how to prevent hazards, such as getting burned by acid, when in a battery room?

Get Price

Practical considerations when designing a battery

Where possible, it is usual to place a standard wall cabinet outside the battery room next to the door, so in the case of an emergency, the voltage

Get Price

Habitable Rooms and Restricted Locations for Battery

When installing the battery on a wall shared with a habitable room that is made of combustible material (e.g. wood), a non-combustible barrier

Get Price

Server Rack Spacing: Best Practices | Sysracks

Another factor influencing the distance between cabinets is the ease of maintenance. System administrators should have enough space to move freely and maintain

Get Price

What Is The Optimum Distance For

Learn about the ideal distance between kitchen cabinets and windows to ensure proper functionality and aesthetics in your

Get Price

How to Determine the Perfect Desk Clearance

Additionally, consider the width of the chair and the space it occupies when determining the distance between the desk and other furniture

Get Price

Habitable Rooms and Restricted Locations for Battery Installation

When installing the battery on a wall shared with a habitable room that is made of combustible material (e.g. wood), a non-combustible barrier must be placed between the

Get Price

EG4 BESS Spacing

The following document clarifies BESS (Battery Energy Storage System) spacing requirements for the EG4 WallMount batteries / rack mount six slot battery cabinet installations.

Get Price

Spaces About Battery Systems | UpCodes

For battery racks, a minimum clearance of 25 mm (1 inch) is required between cell containers and adjacent walls on non-access sides. Battery stands may touch walls, but the shelf must

Get Price

Safety Clearance Recommendations for Electrical Panel

One Entrance at each end of the equipment. Get access to premium HV/MV/LV technical articles, electrical engineering guides, research studies and much more! It helps you

Get Price

6 FAQs about [The distance between the battery cabinet and the wall in the computer room]

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

Can a battery be installed in a computer room?

Sometimes they are installed in the same room as the UPS (i.e., electrical equipment room). Local or regional codes may dictate whether batteries are permitted in an electrical room. Smaller UPS systems (e.g, up to 250 kVA) are commonly installed directly in the computer room along with their respective battery cabinets.

Where should a battery be stored?

The best options are outside of habitable rooms if there is a suitably non-combustible material (see below) between the battery and the habitable room. Other options include, a garage, laundry, or storage room if the appropriate clearances between windows, doors, and appliances are maintained.

How many cells can a battery cabinet hold?

One cabinet should be able to hold at least one complete string of cells. Best practice is that strings should not be split between two cabinets in order to ensure reliability of the entire string. Figure 1 - Battery cabinet with top terminal cells

Can a battery be installed on a wall?

Materials deemed suitably non-combustible based on AS 1530.1: When installing the battery on a wall shared with a habitable room that is made of combustible material (e.g. wood), a non-combustible barrier must be placed between the battery and the wall.

More related information

-

Install ESS power base station in the computer room battery cabinet

Install ESS power base station in the computer room battery cabinet

-

Adding a new battery cabinet to the computer room

Adding a new battery cabinet to the computer room

-

Distance requirements between battery cabinet and wall

Distance requirements between battery cabinet and wall

-

Install base station with battery cabinet in weak current room

Install base station with battery cabinet in weak current room

-

Battery cabinet in low voltage distribution room

Battery cabinet in low voltage distribution room

-

Danish special battery cabinet merchants

Danish special battery cabinet merchants

-

Belarusian energy storage cabinet battery production

Belarusian energy storage cabinet battery production

-

Telecom battery cabinet brand

Telecom battery cabinet brand

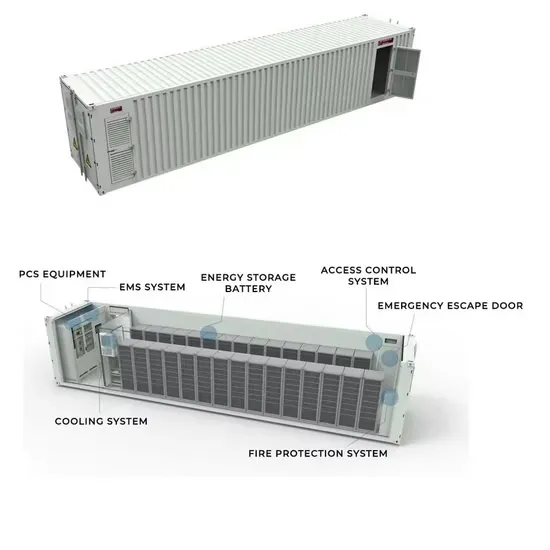

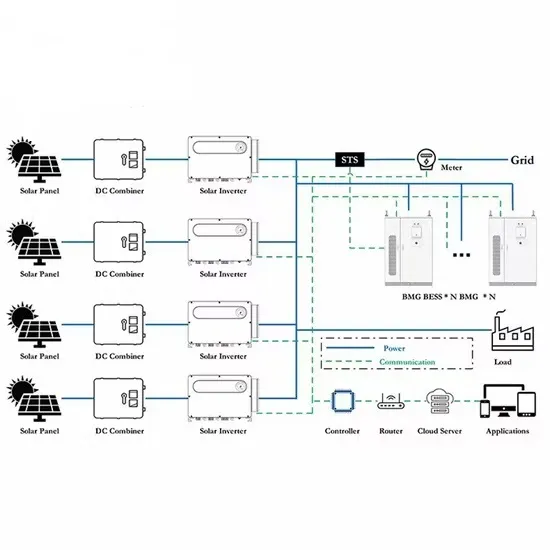

Commercial & Industrial Solar Storage Market Growth

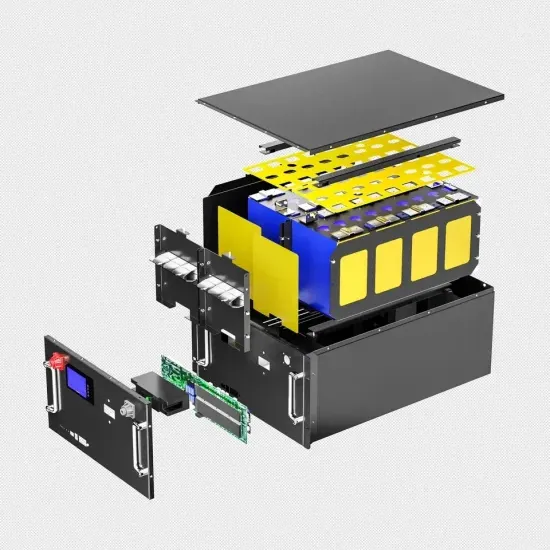

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.