Safe Clearances for Electrical Equipment: Working

Side clearance: There should be a minimum of 30 inches of clearance from the sides of all electrical equipment, but in no case less than the width of the

Get Price

Work Space about battery racks | Information by Electrical

For a battery rack arranged one battery deep by any number of batteries wide and tall, all maintenance can be performed from one side of the rack - just like a switchboard or

Get Price

EG4 BESS Spacing

The following document clarifies BESS (Battery Energy Storage System) spacing requirements for the EG4 WallMount batteries / rack mount six slot battery cabinet installations.

Get Price

2021 International Solar Energy Provisions (ISEP)

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get Price

A guide to kitchen clearances, measurements, and

The areas used for circulation through a kitchen need careful consideration.''Allow at least 36 inches for single-use walkways and 42 to 48

Get Price

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.)

Get Price

The Ultimate Guide to Battery Charging Cabinets:

Understanding the Importance of Battery Charging Cabinets Lithium-ion batteries power many of our everyday devices, from industrial machinery to personal

Get Price

Safe Clearances for Electrical Equipment: Working Space and

Side clearance: There should be a minimum of 30 inches of clearance from the sides of all electrical equipment, but in no case less than the width of the equipment itself. This is referred

Get Price

Safety distance requirements for energy storage cabinets

Electrical energy storage (EES) systems - Part 5-3. Safety requirements for electrochemical based EES systems considering initially non-anticipated modifications, partial replacement,

Get Price

Best Practices and Considerations for Siting Battery Storage

• Depending on the size of the battery and needs of the site, it is important to determine early on if the battery will be sited in the facility or outside of it. • This decision may be impacted by any

Get Price

Safety Clearance Recommendations for Electrical Panel

One Entrance at each end of the equipment. Get access to premium HV/MV/LV technical articles, electrical engineering guides, research studies and much more! It helps you

Get Price

Ventilation of spaces containing batteries 1 General requirements

All battery-installations, except for gastight batteries, in rooms, cabinets and containers shall be con- structed and ventilated in such a way as to prevent the accumulation of ignitable gas

Get Price

Safety Clearance Recommendations for Electrical Panel

One Entrance at each end of the equipment. Get access to premium HV/MV/LV technical articles, electrical engineering guides, research

Get Price

Spaces About Battery Systems | UpCodes

For battery racks, a minimum clearance of 25 mm (1 inch) is required between cell containers and adjacent walls on non-access sides. Battery stands may touch walls, but the shelf must

Get Price

Installation of Inverter and batteries outside

Also consider the weight of the equipment, especially the battery, so you may want to mount it into the wall, not the cabinet. Which means,

Get Price

Data rack clearance

We''ve always gone back and forth on the required space around a data rack and was just wondering if anyone knew for sure if the minimum space between the rear of a data

Get Price

Do Lithium Ion Batteries Require A Battery Room? Storage Requirements

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements.

Get Price

Household Cooking Appliances | UpCodes

Household cooking appliances shall have a vertical clearance above the cooking top of not less than 30 inches (762 mm) to combustible material or metal cabinets. A minimum clearance of

Get Price

Spaces About Stationary Standby Batteries | UpCodes

It specifies that working space should be measured from the battery cabinet''s edge, with a minimum clearance of 25 mm (1 inch) between battery cell containers and adjacent walls on

Get Price

Spaces About Stationary Standby Batteries | UpCodes

The section outlines requirements for the spacing around stationary standby batteries, referencing specific codes for compliance. It specifies that working space should be measured from the

Get Price

Siting and Safety Best Practices for Battery Energy Storage

Finally, state and local building, fire, and zoning requirements should also be met. For the purposes of CPCN review and approval, we recommend that future CPCN applicants with

Get Price

6 Battery Energy Storage Systems — Lithium | UpCodes

The partitions need to extend 6 inches (150 mm) beyond the cabinet or open battery rack. For cabinets that meet UL 9540A, the partitions can be constructed of one layer of 5/8-inch Type X

Get Price

480.9 Battery Locations.

Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any

Get Price

Emergency Lighting Spacing Guide

Our extensive selection of exit signs, emergency lighting units, fluorescent battery packs and emergency power systems meet the requirements for a wide range

Get Price

6 FAQs about [Distance requirements between battery cabinet and wall]

How much space do you need for a battery system?

Spaces about battery systems shall comply with 110.26. Working space shall be measured from the edge of the battery cabinet, racks, or trays. For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance.

What is the minimum clearance for a battery rack?

For battery racks, there shall be a minimum clearance of 25 mm (1 in.) between a cell container and any wall or structure on the side not requiring access for maintenance. Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length.

How far should a lithium battery be from an occupied structure?

Unoccupied Structures housing lithium battery must be located no closer than 100 feet (30 m) to an occupied structure or an identified outdoor use area. A perimeter fence or wall in accordance with the installation's facility standards must be provided not less than 100 feet from the structure.

How do you separate Bess-Li cabinets & open battery racks?

The BESS-Li cabinets or open battery racks must be separated from other BESS-Li cabinets or open battery racks by a minimum of 3 feet (1 m) or by partitions extending from floor to ceiling/roof/floor above. The partitions must be constructed of masonry units. The partitions need to extend 6 inches (150 mm) beyond the cabinet or open battery rack.

Can a battery stand contact a wall?

Battery stands shall be permitted to contact adjacent walls or structures, provided that the battery shelf has a free air space for not less than 90 percent of its length. (D) Top Terminal Batteries.

What type of gypsum board do you need for a battery rack?

The partitions must be constructed of masonry units. The partitions need to extend 6 inches (150 mm) beyond the cabinet or open battery rack. For cabinets that meet UL 9540A, the partitions can be constructed of one layer of 5/8-inch Type X gypsum board on both sides of noncombustible studs.

More related information

-

The distance between the battery cabinet and the wall in the computer room

The distance between the battery cabinet and the wall in the computer room

-

Battery cabinet front and rear distance requirements

Battery cabinet front and rear distance requirements

-

Battery cabinet quality requirements

Battery cabinet quality requirements

-

Technical requirements for battery cabinet assembly automation

Technical requirements for battery cabinet assembly automation

-

What are the requirements for battery cabinet installation

What are the requirements for battery cabinet installation

-

Battery Cabinet Requirements

Battery Cabinet Requirements

-

Is there a 60v battery cabinet in Lesotho

Is there a 60v battery cabinet in Lesotho

-

Qatar outdoor communication battery cabinet quotation base station

Qatar outdoor communication battery cabinet quotation base station

Commercial & Industrial Solar Storage Market Growth

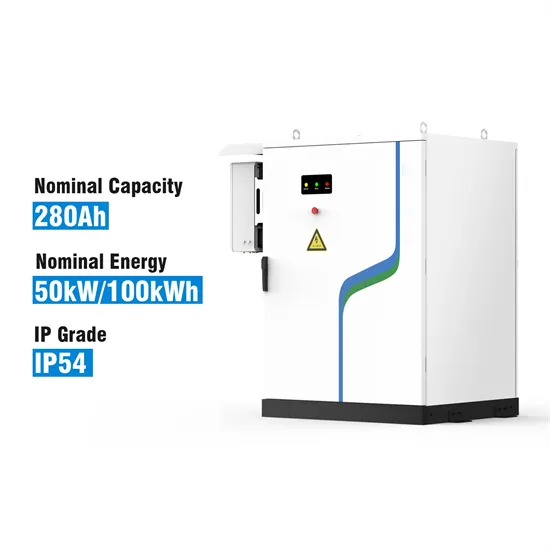

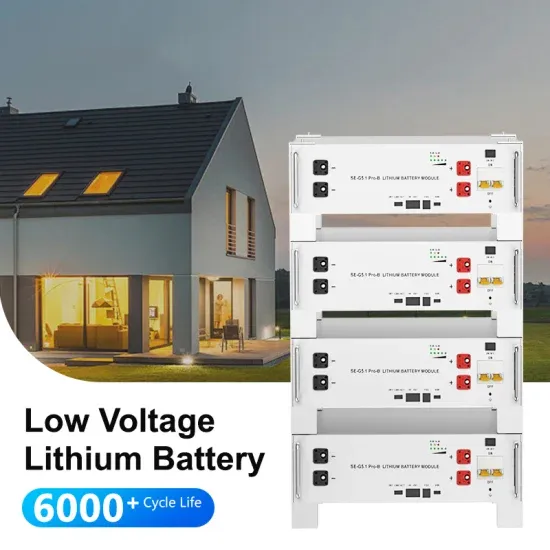

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.