High Frequency Dual-Buck Full-Bridge Inverter Utilizing a Dual

A high frequency dual-buck full-bridge inverter for small power renewable energy applications is proposed in this paper. The implementation of the wide band gap SiC (Silicon Carbide) power

Get Price

Advantages of High-Frequency Inverters in Modern

High-frequency inverters are known for their high efficiency, which is one of their most significant advantages. By operating at higher frequencies, typically in

Get Price

Comparing Carrier-Based PWM Techniques in High

This article explores the potential of carrier-based pulse width modulation techniques such as sawtooth, triangular, and sinusoidal, and

Get Price

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get Price

(PDF) High Frequency Dual-Buck Full-Bridge Inverter

A high frequency dual-buck full-bridge inverter for small power renewable energy applications is proposed in this paper. The implementation

Get Price

Advancing High-Frequency Inverter Design in More Electric

The transition toward aircraft electrification not only reduces the carbon footprint but also advances sustainable aviation, propelling the future of aviation with enhanced performance

Get Price

Review on Silicon Carbide-Based High-Fundamental Frequency

This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output frequencies to enhance

Get Price

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters are typically more efficient at converting power while maintaining a constant load for lighter loads, which is significant when you depend on battery

Get Price

Advantages of High-Frequency Inverters in Modern Applications

High-frequency inverters are known for their high efficiency, which is one of their most significant advantages. By operating at higher frequencies, typically in the range of tens or hundreds of

Get Price

Inversion Methods Explained: High Frequency vs Low Frequency

The large majority of inverters available in the retail market are high frequency. They are typically less expensive, have smaller footprints, and have a lower tolerance for industrial loads.

Get Price

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size

Get Price

Low-Power Silicon-Based Frequency Dividers: An

Frequency divider circuits divide the frequency of an input signal by a specified ratio. They are critical components in analog, digital, and mixed

Get Price

Towards Energy Efficiency: Innovations in High-Frequency

This study reviews advancements in high-frequency converters for renewable energy systems and electric vehicles, emphasizing their role in enhancing energy efficiency

Get Price

Myth Buster: Do Inverter Appliances Really Bring Down the Electricity

With a power inverter, the appliance''s compressor motor will be controlled at a steady rate, consequently reducing the amount of power that is used when turning the motor

Get Price

High-Frequency Inverter: How They Work and Why

The working principle of a high-frequency inverter is the same as that of a regular inverter that converts DC to AC but at a high frequency. It

Get Price

Fundamentals of VLSI CMOS Power Consumption

Power Bottleneck Complex, large and costly power supply circuits: Three-phase step-down converter built from toroidal coils, power MOSFETs, and electrolytic capacitors.

Get Price

Comparing Inverter Solutions: Silicon vs. Wide Bandgap Power

This article explores the differences between inverters based on silicon power devices and those utilizing WBG technologies, evaluating their advantages, disadvantages,

Get Price

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for

Get Price

High-Frequency Inverter: How They Work and Why They Matter

The working principle of a high-frequency inverter is the same as that of a regular inverter that converts DC to AC but at a high frequency. It involves a series of sophisticated components to

Get Price

Review on Silicon Carbide-Based High-Fundamental Frequency Inverters

This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output frequencies to enhance

Get Price

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size and weight, etc., and compares

Get Price

Bus Bar Design for High-Power Inverters

Bus bars have been present in power distribution systems for many years. In their most basic form, bus bars are large conductors used to transmit significant quantities of current where a

Get Price

Does Inverter Air Conditioner Save Electricity

This innovative technology minimizes energy wastage caused by excessive starts and stops, ensuring a more efficient operation. By

Get Price

Analysis of Power Loss and Improved Simulation Method of a High

A high frequency dual-buck full-bridge inverter for small power renewable energy application is proposed in this paper. A switching frequency of 400 kHz is achieved with the adoption of the

Get Price

High Frequency Dual-Buck Full-Bridge Inverter Utilizing a Du

A high frequency dual-buck full-bridge inverter for small power renewable energy applications is proposed in this paper. The implementation of the wide band gap SiC (Silicon Carbide) power

Get Price

Review on Silicon Carbide based High-Fundamental

Recent research and development efforts in SiC inverters for electric drive applications highlight a strong focus on achieving high power density, high efficiency, and high-frequency

Get Price

Comparing Inverter Solutions: Silicon vs. Wide

This article explores the differences between inverters based on silicon power devices and those utilizing WBG technologies, evaluating their

Get Price

6 FAQs about [High frequency dual silicon inverter consumes electricity]

Are high-frequency inverters better than low-frequency?

Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers. Efficiency: High-frequency inverters are generally more efficient than low-frequency inverters for maintaining a constant load for lighter loads. However, they may struggle with high surge currents or heavy loads.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

Why are high frequency inverters more efficient?

In contrast, high-frequency inverters can use smaller-sized and lighter-weight components due to their use of higher frequencies, resulting in smaller overall size and weight. Efficiency: Since the high frequency inverter uses high-frequency switches for inversion, its switching loss is relatively small, so it has higher conversion efficiency.

Why do solar inverters use silicon MOSFETs?

Silicon MOSFETs, by contrast, are primarily used in lower-power applications within solar inverters due to their fast-switching speeds and low gate drive power requirements. These characteristics enhance overall efficiency, particularly in compact, high-frequency inverter designs.

Why do silicon based inverters require bulky cooling solutions?

The relatively slow switching frequency of IGBTs results in higher energy losses in applications demanding rapid switching, such as high-speed motor drives. Additionally, silicon-based inverters often require bulky cooling solutions due to higher heat dissipation, which increases system size and weight.

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

More related information

-

Silicon Carbide High Frequency Inverter

Silicon Carbide High Frequency Inverter

-

High frequency inverter price in Latvia

High frequency inverter price in Latvia

-

Is the grid-connected inverter industrial frequency or high frequency

Is the grid-connected inverter industrial frequency or high frequency

-

What is the use of high frequency inverter

What is the use of high frequency inverter

-

The frequency on the high-voltage side of the inverter is too high

The frequency on the high-voltage side of the inverter is too high

-

High frequency inverter frequency

High frequency inverter frequency

-

Eritrea high frequency inverter

Eritrea high frequency inverter

-

Kiribati high frequency inverter

Kiribati high frequency inverter

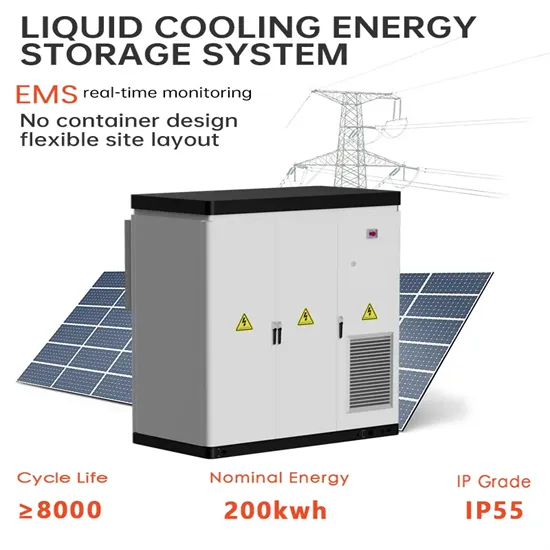

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

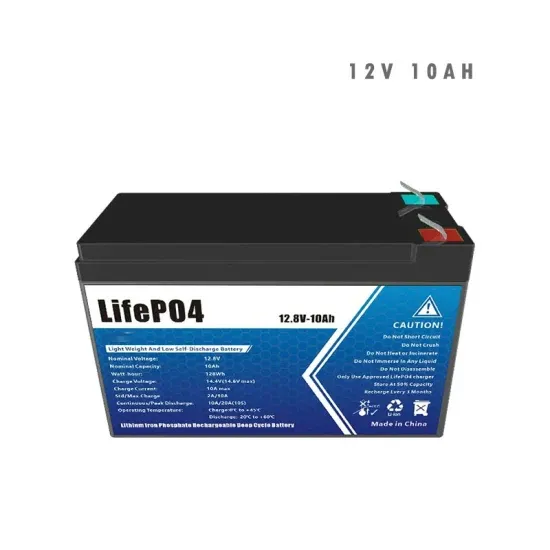

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.