Utility-scale battery energy storage system (BESS)

This reference design focuses on an FTM utility-scale battery storage system with a typical storage capacity ranging from around a few megawatt-hours (MWh) to hundreds of MWh.

Get Price

Energy Storage Battery Pack Enclosure size optimization and

Learn about the industry-leading ESS Battery Enclosure specifications and efficient layout strategies of CATL, BYD, etc., to improve system space utilization and reliability.

Get Price

Considerations for Using Lithium-ion Batteries with UPS

Introduction Lithium ion (Li-ion) battery technology is making its inroads into high availability applications, including data centers. Failure of a data center''s uninterruptable power supply

Get Price

Battery Rack Cabinet | Telecom Battery Rack | Rack Battery Cabinet

Explore Battery Rack Cabinets from Charles Industries. Secure, efficient indoor solutions for telecom and power storage needs. Enquire now!

Get Price

A support approach for the modular design of Li-ion batteries: A

A lot of the past studies are focused on traditional schemes of battery layout. However, the design of battery packs requires the definition of novel configurations because a

Get Price

Samsung UL9540A Lithium-ion Battery Energy Storage

Overview The Samsung SDI 128S and 136S energy storage systems for data center application are the first lithium-ion battery cabinets to fulfill the rack-level safety standards of the UL9540A

Get Price

BATTERY CABINET

An existing PWRcell Battery Cabinet can be upgraded with additional modules. Use the graphic below and the chart on the back of this sheet to understand what components you need for

Get Price

LFP ESS Cabinet & Components

The modular design allows easy assembly and installation of four (4) 4U height rack-mount batteries. [S48-100LFP ESS] Magnetic front & rear panels provide added protection as well as

Get Price

A Comprehensive Guide to Telecom Battery Cabinets

A comprehensive guide to telecom battery cabinets provides essential information on their features, types, selection criteria, installation tips, and innovations in technology.

Get Price

Uninterruptible Power Supply (UPS) Backup Battery

Battery Cabinets Arimon designs and manufactures custom uninterruptible power supply (UPS) backup battery cabinets, battery racks and accessories for the

Get Price

How to design an energy storage cabinet: integration and

This article will detail how to design an energy storage cabinet, especially considering the integration of core components such as PCS, EMS, lithium batteries, BMS,

Get Price

Complete Guide for Battery Enclosure

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using

Get Price

Complete Guide for Battery Enclosure

From battery box design, and fabrication, to quality inspection – our team handles every process for you. Our team will help you choose the right material, recommend the best

Get Price

3-Phase Modular UPS Battery Cabinets

The CyberPower BCT3L9N125 3-Phase Modular UPS Battery Cabinet can hold up to 6 battery modules (BM120V30ATY). These 3-layer units can be

Get Price

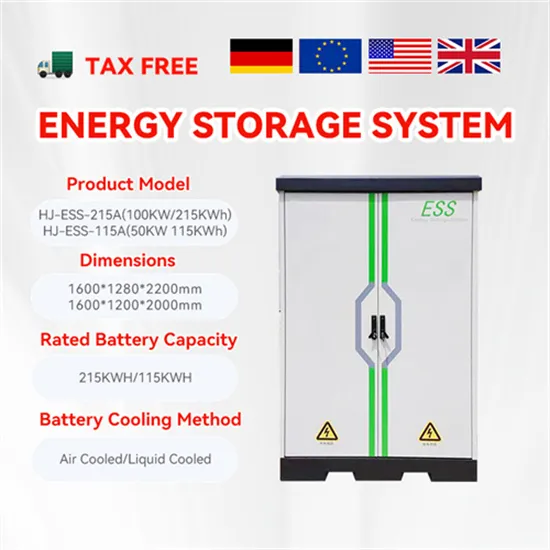

Power Backup LiFePO4 215kWh 430kwh 1MWh All In

Namkoo NKB Series 215kwh commercial & industrial energy storage system adopts the all in one design concept.The cabinet is integrated with battery

Get Price

Lithium battery module design production process and trends

This article will introduce you to the characteristics, design and production process, key points, and development trend of lithium battery module structure design.

Get Price

Choosing the Right Battery Storage Cabinet: A Comprehensive

This comprehensive guide provides a detailed overview of safety, design, compliance, and operational considerations for selecting and using lithium-ion battery storage

Get Price

Enclosure Design

A look at the key elements of a battery pack enclosure design. This design will change based on the size and application, but it is still worth approaching this from a high level.

Get Price

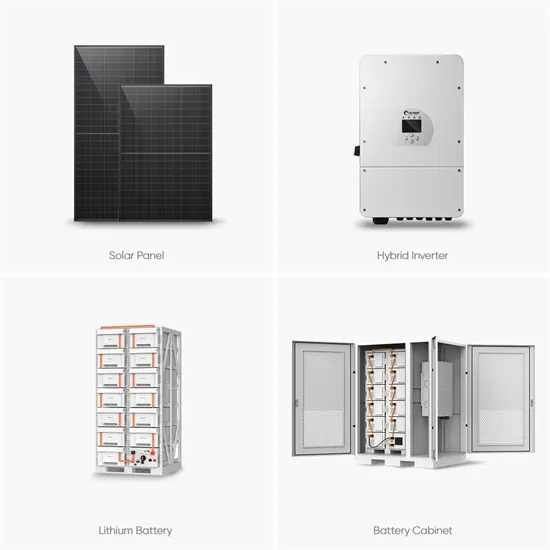

What Are Battery Cells, Battery Modules, And Battery

Here we''ll talk about the differences between battery cells, modules, and packs, and learn how to tell these key components for effective

Get Price

Battery Cabinet Modular Design: Revolutionizing Energy Storage

When Germany''s largest seaport needed 80MWh peak shaving capacity, Siemens Energy deployed modular battery cabinets with liquid-cooled stacking. The result? 14% faster

Get Price

What Are Battery Rack Cabinets and Why Are They Essential?

Battery rack cabinets are secure, organized, and often climate-controlled enclosures designed to safely store, protect, and charge multiple batteries, especially lithium

Get Price

Battery Cabinets – City Solar

BYD B-BOX CABINET (4 X 2.5) The BYD B-Box Energy Storage System utilizes the BYD Iron Phosphate battery in a modular design that allows the flexibility to use up to four battery

Get Price

Easy UPS 3S Modular Battery Cabinet, 208V

Modular battery cabinet for extended runtime for UPSs with internal batteries. The cabinet is supplied without batteries, so batteries must be purchased separately.

Get Price

ESS Modules & Racks

The cabinets of our eco-friendly battery energy storage system modules and racks have a modular design which helps to meet higher energy storage

Get Price

Battery Module Cabinet Guide: Definition, Uses & Design

3 days ago· A Battery Module Cabinet stores and manages battery modules for UPS, telecom, and energy storage, ensuring safety, scalability, and efficiency.

Get Price

6 FAQs about [Battery cabinet module design]

What is a lithium battery module design process?

The whole lithium battery module design process actually includes you have to mean the whole module design goal, integrate the details of the module design, and have a complete set of verification process of the module design, including the structure, electrical, cooling safety several parts, all of which have to be implemented in it.

What type of batteries are used in energy storage cabinets?

Lithium batteries have become the most commonly used battery type in modern energy storage cabinets due to their high energy density, long life, low self-discharge rate and fast charge and discharge speed.

What are the parts of a battery storage cabinet?

Let’s look at the most common parts: Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels. Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure.

How to install a battery storage cabinet?

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately. Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

How do you choose a battery cabinet?

Again, the door should have a safe locking mechanism or latch. In more advanced battery cabinets, they may have alarm systems. Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section. Ventilation systems also help during the cooling process.

How to build a battery cabinet?

Step 1: Use CAD software to design the enclosure. You must specify all features at this stage. Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication. Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes.

More related information

-

Battery cabinet explosion-proof design

Battery cabinet explosion-proof design

-

Battery cabinet design requirements

Battery cabinet design requirements

-

Power design of battery energy storage cabinet

Power design of battery energy storage cabinet

-

Battery cabinet waterproof design solution

Battery cabinet waterproof design solution

-

The current of each module in the battery cabinet

The current of each module in the battery cabinet

-

Battery cabinet production design

Battery cabinet production design

-

Battery cabinet overcurrent protection design

Battery cabinet overcurrent protection design

-

Outdoor battery cabinet design elements

Outdoor battery cabinet design elements

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.