The starting voltage of the inverter is higher than the minimum voltage

In photovoltaic inverters, there is a rather strange parameter, that is, the inverter input starting voltage. This voltage is approximately 30V higher than the minimum operating voltage. For

Get Price

Inverter Battery Voltage: How Many Volts Are Needed For

Next, we will explore how to select the right inverter battery based on your specific needs and the factors that influence battery lifespan and performance. This guidance will

Get Price

Frequently Asked Questions about Inverters

As a rule of thumb you should divide the connected capacity by 10 for 12 volt and by 20 for 24 volt. This also includes all the power losses in the cables, fuses and the inverter. Is there a

Get Price

batteries

On this basis, I have set the inverter''s auto cut off setting to 11.5V. Sometimes the voltage drops to 11.5V or less and I lose power even though the battery''s actual voltage is

Get Price

Powering Your Dreams: A Comprehensive Guide to Selecting the

Selecting the right battery size for your 3000 watt inverter requires careful consideration of various factors, including inverter capacity, DOD, system voltage, Ah

Get Price

When choosing an inverter, what voltage ratings

It''s vital to match the inverter''s battery voltage rating with that of your energy storage system for smooth, safe operation. Most inverters now come with

Get Price

How to choose the right inverter and battery for your home

Here is how you can calculate your electricity needs and buy an inverter and battery accordingly.

Get Price

Understanding Optimal Battery Voltage: A Comprehensive Guide

A 3000W inverter typically requires a continuous power supply of about 3000 watts to function effectively, with additional surge power requirements that can significantly exceed

Get Price

Understanding Battery Specifications and How They Apply to your Inverter

Without the correct amount of battery preparation, an exciting inverter set up can quickly turn into a frustrating experience. Hopefully you are now equipped with a better understanding of how

Get Price

Understanding inverter voltage

Low output inverter voltage can stem from issues such as a weak battery, loose connections, or internal faults. Thoroughly troubleshooting these aspects can help identify and

Get Price

How to Choose the Right Inverter Battery Voltage for Your Needs

Understanding inverter battery voltage is key to creating a strong and dependable power system. This detailed guide explores how to choose the right voltage, offers tips for

Get Price

When choosing an inverter, what voltage ratings should you pay

It''s vital to match the inverter''s battery voltage rating with that of your energy storage system for smooth, safe operation. Most inverters now come with multiple battery voltage options,

Get Price

Understanding inverter voltage

Low output inverter voltage can stem from issues such as a weak battery, loose connections, or internal faults. Thoroughly troubleshooting these

Get Price

What is inverter start up voltage | DIY Solar Power Forum

Question is I''m hoping to fit a proper home inverter but the minimum ''startup'' voltage i see is approximately 50v. Does this mean as I have only one solar panel kicking out

Get Price

How to Calculate the Right Inverter Battery Capacity

Learn how to calculate the right inverter battery capacity for your needs with a simple formula. Understand power requirements, efficiency

Get Price

Minimum Battery Requirements Again! How is it calculated? A

Assuming the batteries could get charged by full power in an uncontrolled manner through the AC coupled PV inverter, for a 1 kW PV to a ~5kWh Battery@100Ah/48V, you

Get Price

4. Configuration

Do not use the "Dynamic cut off" feature in an installation that also has other loads connected to the same battery. In these systems the battery voltage might drop because of other loads

Get Price

Inverter Battery Voltage Chart

A clear understanding of the inverter battery voltage chart is essential for effective battery management and performance. This section covers how to interpret the chart, the

Get Price

Battery Voltage Explained: Nominal, Charged, Minimum, and Cut

When selecting a lithium-ion battery pack, understanding its voltage characteristics is crucial for ensuring optimal performance and longevity. Three key voltage terms define a

Get Price

PowMr inverter setup question : r/SolarDIY

I''m having trouble with an PowMr model POW-LVM5.0K-48V-H inverter indicating full charge on my batteries. link to inverter I am only seeing one bar indicated

Get Price

LiFe and Eco Series Battery Settings for Solis Inverters

How many batteries do I need? Minimum battery size should be greater than the rated peak output of the inverter. Battery to PV ratio is no less than 2.5kWh (battery) : 1kw (PV). The

Get Price

Battery Runtime Calculator | How Long Can A Battery Last

The Battery Runtime Calculator is an indispensable tool for anyone using batteries for power supply, be it in RVs, boats, off-grid systems, or even in everyday electronics. This

Get Price

Understanding Battery Specifications and How They

Without the correct amount of battery preparation, an exciting inverter set up can quickly turn into a frustrating experience. Hopefully you are now equipped with

Get Price

Inverter DC input minimum voltage too hight for battery pack

I want to store the energy in my battery pack 12v but i can make it to 24v. The big problem is that the inverter has a minimum DC input of 100v (220v nominal). The kit is huge :

Get Price

Charger and Inverter Settings

Charger and inverter settings for SOK batteries General settings that apply to most equipment. Multiply voltages by 2 for 24v systems and by 4 for 48v systems. Charge Current (Per battery):

Get Price

Su-vastika : The future of home energy storage

Store the Lithium deep cycle lead acid battery in a cool, dry place. Here are some signs that a tubular battery is fully charged: The battery

Get Price

6 FAQs about [Battery with inverter minimum voltage]

How low can a battery be charged by a PV inverter?

My thinking on this: Assuming the batteries could get charged by full power in an uncontrolled manner through the AC coupled PV inverter, for a 1 kW PV to a ~5kWh Battery@100Ah/48V, you would be charging at about 0.2C which is low enough. And for Lithium Ion at about 0.3C which is also quite low.

How many volts does an inverter need?

For grid-tied systems, this is typically 220V or 230V in most countries. For off-grid systems, it might be 48V or 24V, depending on your battery configuration. Ensuring this rating matches your power system's output guarantees that your inverter will efficiently convert energy without risk of damage.

Do solar inverters have multiple battery voltage options?

Most inverters now come with multiple battery voltage options, allowing for greater flexibility in system design. Understanding the voltage ratings of your inverter ensures safe, efficient, and reliable solar energy production.

How much battery does a 12 volt inverter need?

As a rule of thumb, the minimum required battery capacity for a 12-volt system is around 20 % of the inverter capacity. For 24-volt inverters, it is 10 %. The battery capacity for a 12-volt Mass Sine 12/1200, for instance, is 240 Ah, while a 24-volt Mass Sine 24/1500 inverter would require at least 150 Ah.

What is the start voltage of a 12V inverter?

In the case of a 12V inverter, the start inverter voltage is typically around 9.5VDC. This threshold ensures that the inverter can begin its operation reliably without placing undue stress on the connected battery. What is cut off voltage in inverter?

Can a battery run an inverter?

The first major issue with using this rating for inverter use is the terminal voltage rating of 7.2V. Let’s say that a battery can produce 300 DC amps for 30 seconds, while maintaining 7.2V. While this is great for starting a cold engine, it is not for running an inverter.

More related information

-

What is the output voltage of the battery connected to the inverter

What is the output voltage of the battery connected to the inverter

-

Micro inverter battery boost voltage

Micro inverter battery boost voltage

-

Inverter battery maximum voltage

Inverter battery maximum voltage

-

72v battery low voltage protection inverter structure

72v battery low voltage protection inverter structure

-

48v battery inverter voltage regulation

48v battery inverter voltage regulation

-

What size inverter should I use with a 24ah lithium battery

What size inverter should I use with a 24ah lithium battery

-

Chad lithium battery inverter manufacturer

Chad lithium battery inverter manufacturer

-

What is the inverter input voltage

What is the inverter input voltage

Commercial & Industrial Solar Storage Market Growth

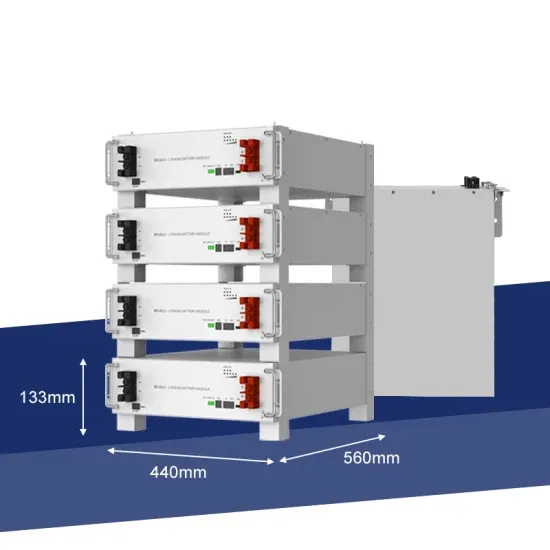

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.