Mastering the Lithium Battery Pack Assembly Process

Explore how to achieve safe and efficient lithium battery pack assembly through precise layout planning, expert welding, and rigorous battery testing protocols.

Get Price

How to Assemble a Lithium Battery Pack: Step-by-Step Guide for

Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get Price

EV Car Battery Assembly,Electric Bike Battery Assembly

We also supply all kinds of EV Car Battery Assembly,Electric Bike Battery Assembly for you! We can assure our customers of our products with high quality,best services and a reasonable price.

Get Price

How to Assemble a Lithium-Ion Battery Pack with a BMS Module:

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed assembly instructions, and testing

Get Price

Battery Cell Contact System for EV Lithium Battery

Lithium battery packs are the power source for electric vehicles (EVs) and hybrid electric vehicles (HEVs). In a lithium battery pack, the cell

Get Price

The Manufacturing Process of Lithium Batteries Explained

During the cell assembly stage of the lithium battery manufacturing process, we carefully layer the separator between the anode and cathode. This can be done through stacking or winding

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring

Get Price

Lithium Battery Pack Assembly: A Comprehensive Guide

Join us as we delve into the intricate art of lithium battery pack assembly, unveiling the expertise and precision engineering required to bring these cutting-edge technologies to life.

Get Price

Prismatic Battery Pack Assembly – Precision & Efficiency

Fully automated prismatic battery assembly line, delivering high-capacity packs with precision engineering for diverse applications.

Get Price

Semi-Automatic Lithium-ion Battery Assembly Line

A Semi-Automatic Lithium-Ion Battery Assembly Line represents a cutting-edge solution for the efficient assembly of lithium battery modules.

Get Price

Lithium Battery Assembly: How to Build Battery Pack

Building my own lithium battery pack was a challenging yet rewarding experience that allowed me to gain a deeper appreciation for this

Get Price

How to Assemble a Lithium Battery Pack Lithium Battery

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get Price

Battery Pack Manufacturing Process: Step-by-Step

Learn the steps behind battery pack manufacturing, from cell assembly to BMS integration, ensuring reliable power for diverse applications.

Get Price

Design approaches for Li-ion battery packs: A review

The target concerns electric and hybrid vehicles and energy storage systems in general. The paper makes an original classification of past works defining seven levels of

Get Price

9 Steps to Know How a Battery Pack Is Made

How a Battery Pack Is Made: Raw material selection, cell sorting and matching, BMS integration, cell module assembly, pack assembly...

Get Price

How Are Lithium Battery Packs Assembled?

The assembly process of lithium battery packs is crucial for ensuring their optimal performance, safety, and longevity. This article explores the key steps involved in lithium battery pack

Get Price

How to Assemble a Lithium Battery Pack Lithium Battery Assembly

️In this video, we walk you through the complete process of assembling a lithium battery pack — from selecting the right cells to final wiring and safety ch...

Get Price

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get Price

How to Build a Lithium Ion Battery Pack? A Step by Step Guide

In this article, we will have an in-depth discussion on how to build a lithium ion battery pack? We will provide a step by step guide that we hope will help you understand the

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase

Get Price

Battery Pack Assembly : 5 Steps

Battery Pack Assembly: The goal of this project is to create a battery pack from purchased power cells. Is important to understand how cells can be connected

Get Price

How to Build a Lithium Ion Battery Pack: Expert Guide for Engineers

All essential components of a lithium ion battery pack are addressed to support engineers developing both simple portable devices and complex motive applications. The

Get Price

How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get Price

Assembly line for battery modules and battery packs

For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These systems are

Get Price

Different Stages of Battery Pack Assembly at iPower Batteries

Battery packs are the backbone of modern energy storage solutions, powering everything from electric vehicles to renewable energy systems. At iPower Batteries, a leading

Get Price

Lithium Battery Assembly: How to Build Battery Pack

Building my own lithium battery pack was a challenging yet rewarding experience that allowed me to gain a deeper appreciation for this technology. In this article, I''ll share my

Get Price

Lithium-Ion Battery Pack Manufacturing Process Guide

The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each phase plays a critical role in ensuring the

Get Price

More related information

-

Lithium battery assembly double pack

Lithium battery assembly double pack

-

Where can I buy lithium battery packs in Luxembourg

Where can I buy lithium battery packs in Luxembourg

-

Specialized production of lithium battery packs

Specialized production of lithium battery packs

-

Energy conversion efficiency of lithium battery packs

Energy conversion efficiency of lithium battery packs

-

Only lithium battery packs

Only lithium battery packs

-

Benefits of Libyan solar lithium battery packs

Benefits of Libyan solar lithium battery packs

-

What equipment should be used with lithium battery packs

What equipment should be used with lithium battery packs

-

Timor-Leste makes lithium battery packs at home

Timor-Leste makes lithium battery packs at home

Commercial & Industrial Solar Storage Market Growth

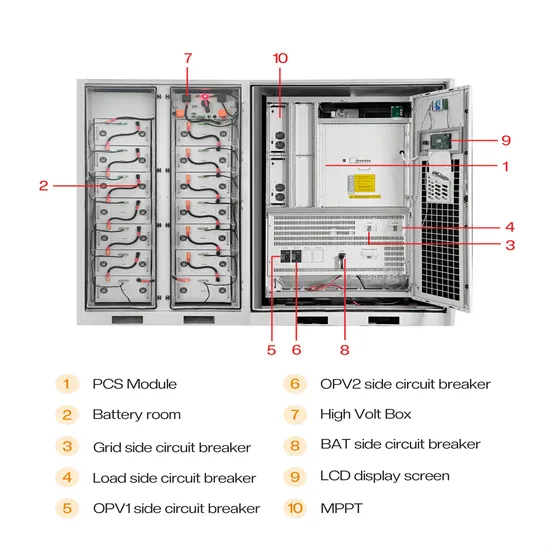

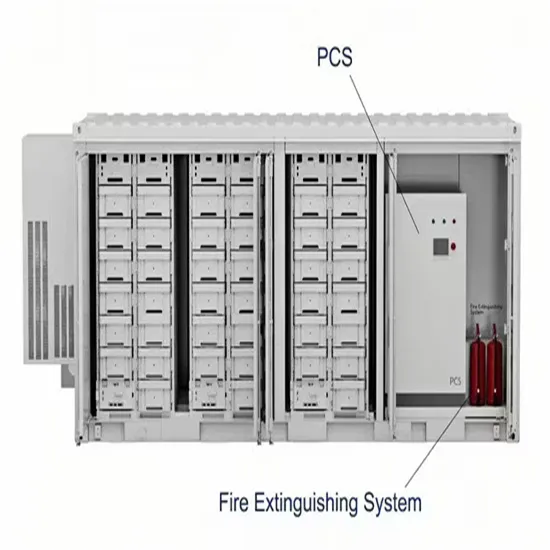

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.