Outdoor energy storage battery heat dissipation

Do lithium-ion batteries have thermal runaway? Therefore, for lithium-ion batteries, the mechanism and reaction process of thermal runaway should be ascertained. Furthermore, it is

Get Price

How Do Rack Batteries Improve Heat Dissipation in Tropical

Rack batteries enhance heat dissipation in tropical microgrids through advanced thermal management systems, optimized airflow designs, and heat-resistant materials. These

Get Price

Heat-dissipation basics for EV batteries

Li-ion batteries are as sensitive to temperature as chemical reaction catalysts in the actual usage. Therefore the purpose of heat dissipation is to provide an appropriate

Get Price

Cross discipline Fluency: | C&I Energy Storage System

Articles related (50%) to "Cross discipline Fluency:" Energy Storage Campus Recruitment 2025: Your Gateway to Powering the Future The global energy storage market is projected to grow

Get Price

Thermal conductive interface materials and heat

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage

Get Price

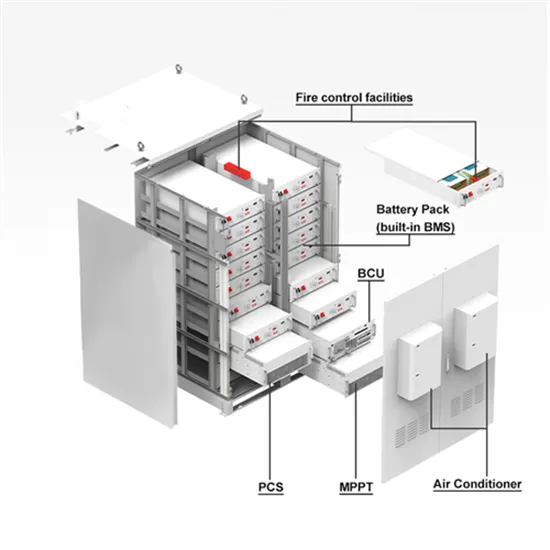

THERMAL MANAGEMENT FOR ENERGY

To maintain the temperature within the container at the normal operating temperature of the battery, current energy storage containers have

Get Price

Numerical study on heat dissipation performance of a lithium-ion

The simulation model is validated by the experimental data of a single adiabatic bare battery in the literature, and the current battery thermal management system based on

Get Price

A thermal management system for an energy storage battery

Therefore, lithium battery energy storage systems have become the preferred system for the construction of energy storage systems [6], [7], [8]. However, with the rapid

Get Price

The Heat Dissipation and Thermal Control Technology of Battery

The heat dissipation and thermal control technology of the battery pack determine the safe and stable operation of the energy storage system. In this paper, the

Get Price

Internal Heat Dissipation Methods for Energy Storage Batteries

Summary: This article explores advanced heat dissipation techniques for energy storage batteries, their applications across industries, and real-world case studies. Discover how

Get Price

Energy storage battery heat dissipation principle

In the context of battery thermal management, effective heat dissipation is crucial for ensuring that batteries do not overheat, which can lead to reduced performance, safety hazards, and

Get Price

Heat dissipation

Heat dissipation refers to the process of transferring heat away from an object, typically to maintain a safe operating temperature. In the context of battery thermal management, effective

Get Price

Introduction on Heat Dissipation Technology of Energy Storage Battery

Li-ion batteries are as sensitive to temperature as chemical reaction catalysts in the actual usage. Therefore the purpose of heat dissipation is to provide an appropriate

Get Price

Numerical simulation and optimal design of heat dissipation of

Container energy storage is one of the key parts of the new power system. In this paper, multiple high rate discharge lithium-ion batteries are applied to the rectangular battery pack of

Get Price

Thermal conductive interface materials and heat dissipation of energy

This article will introduce you the mainstream heat dissipation methods and thermal conductive interface materials of energy storage modules, including the classifications

Get Price

THERMAL MANAGEMENT FOR ENERGY STORAGE:

To maintain the temperature within the container at the normal operating temperature of the battery, current energy storage containers have two main heat dissipation

Get Price

Heat dissipation

Heat dissipation is essential for battery safety, as excessive heat can lead to thermal runaway, which can cause fires or explosions. Effective battery thermal management systems employ

Get Price

Thermal effects of solid-state batteries at different temperature

As most of the applications involve temperature-dependent performances, the thermal effects may have profound influences on achieving practically accessible solid-state

Get Price

Energy storage battery container heat dissipation

Do lithium-ion batteries perform well in a container storage system? This work focuses on the heat dissipation performance of lithium-ion batteries for the container storage system. The CFD

Get Price

Multi-scale modelling of battery cooling systems for grid frequency

The introduction of battery energy storage systems is crucial for addressing the challenges associated with reduced grid stability that arise from the large-scale integration of

Get Price

Heat-dissipation basics for EV batteries

Designing a battery module or pack requires balancing several competing thermal factors. The most common strategy is to provide just-enough thermal management to achieve

Get Price

How does energy storage dissipate heat? | NenPower

Heat dissipation in energy storage systems significantly relies on thermal conduction, the process by which heat moves from regions of higher temperature to lower

Get Price

What is the heat dissipation temperature of the energy storage battery

HEAT DISSIPATION IN ENERGY STORAGE BATTERIES IS A CRUCIAL FACTOR in their overall effectiveness, performance, and safety. A detailed understanding of

Get Price

How does the energy storage battery dissipate heat?

Energy storage batteries dissipate heat via various channels, including conduction, convection, and radiation. Heat generation is intrinsic to typical operation, arising from internal

Get Price

LFP Battery Pack Combined Heat Dissipation Strategy Structural

Abstract: During the high-power charging and discharging process, the heat generated by the energy storage battery increases significantly, causing the battery temperature to rise sharply

Get Price

6 FAQs about [Do energy storage batteries need heat dissipation ]

How does heat dissipation and thermal control technology affect energy storage system?

Abstract: The heat dissipation and thermal control technology of the battery pack determine the safe and stable operation of the energy storage system. In this paper, the problem of ventilation and heat dissipation among the battery cell, battery pack and module is analyzed in detail, and its thermal control technology is described.

How to isolate battery cells to protect against heat propagation?

The primary strategies to isolate battery cells to protect against heat propagation all have pluses and minuses. Designing a battery module or pack requires balancing several competing thermal factors. The most common strategy is to provide just-enough thermal management to achieve the battery pack’s fundamental goals.

How to prevent thermal propagation in cell battery packs?

Spreading is the best way to prevent thermal propagation in pouch and prismatic cell battery packs because it prevents propagation while extending cell cycle lifetime and fast charging while cutting size and weight. Flexible graphite heat spreaders outperform aluminum and can support high-performance, small, lightweight battery packs.

What happens if a battery is overheated?

As mentioned previously, local overheating will induce metallic dendrites, which will cause fractures, pulverization, and internal short circuit. Thermal stress/thermal strain can be generated by temperature increase and high expansion coefficient can lead to volume changes and battery deformation.

How does heat generation affect battery performance?

Heat generation usually acts as the initial step for thermal failure. As the time goes by during the aging process, the accumulated side effects from heat generation will lay negative impacts on battery performances, greatly jeopardizing the overall stability. These side effects can be termed as aging effect.

Which solid-state batteries have thermal effects?

Thermal effects in non-lithium based solid-state batteries Owing to the demonstrated electrochemical performances and technical maturity, SSLBs appear to be the most prevailing solid-state batteries. However, searching for other alternatives is important as the resources for lithium are limited.

More related information

-

Heat dissipation of energy storage batteries

Heat dissipation of energy storage batteries

-

Heat dissipation of energy storage system in communication base station

Heat dissipation of energy storage system in communication base station

-

Energy storage equipment heat dissipation

Energy storage equipment heat dissipation

-

Current status of heat dissipation in communication base station energy storage systems

Current status of heat dissipation in communication base station energy storage systems

-

Liquid-cooled energy storage battery cabinet heat dissipation

Liquid-cooled energy storage battery cabinet heat dissipation

-

Reliable communication base station energy storage system heat dissipation

Reliable communication base station energy storage system heat dissipation

-

Flywheel energy storage motor heat dissipation

Flywheel energy storage motor heat dissipation

-

Enterprises that need energy storage batteries

Enterprises that need energy storage batteries

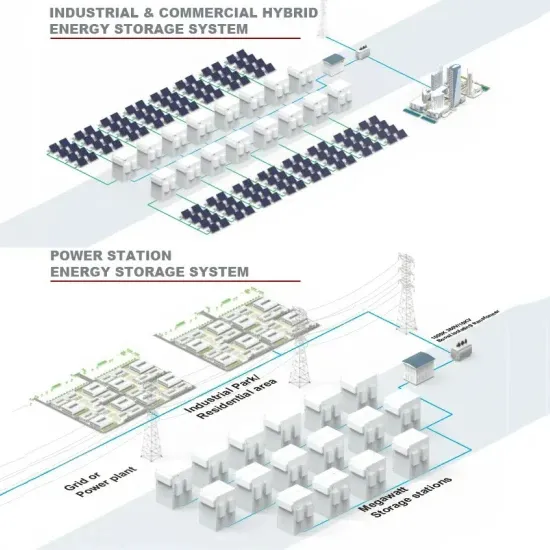

Commercial & Industrial Solar Storage Market Growth

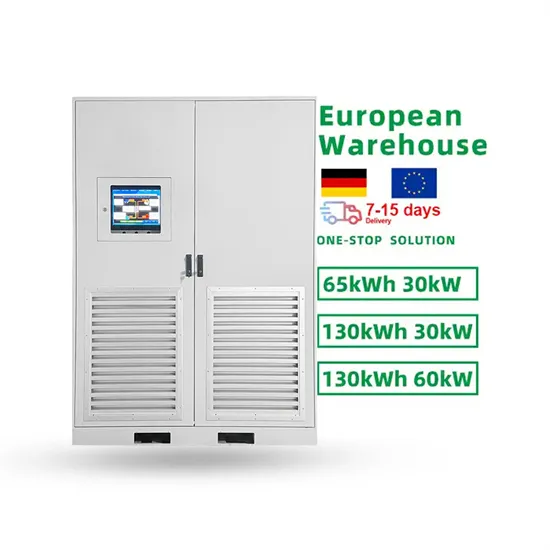

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.