Li-ion Battery Pack Balance

When charging and discharging lithium-ion battery packs, we can take balanced measures to ensure safety and stability if we take into account the inconsistencies of each single

Get Price

The Significance of Cell Balancing in Lithium Packs

Part 1. The need for lithium-ion battery packs Before diving into cell balancing, let''s first understand why lithium-ion battery packs are in high

Get Price

The Significance of Cell Balancing in Lithium Packs

To sum it up, cell balancing is super essential for getting the most out of lithium-ion battery packs. By ensuring each cell has an equal charge,

Get Price

Balance Lithium Cells or Not?

The discharge current doesn''t need to be high because most things in a battery pack are slow processes. Something else to consider is that balancing can only be done when

Get Price

Cell Balancing

Any algorithm needs testing on new and old packs to ensure that it is stable. Do we balance when charging or discharging? Balance when charging and at a

Get Price

Can a Battery Pack Self-Balance? Exploring Cell Balancing in

Cell balancing is crucial for battery performance because it ensures that each cell in a battery pack operates at the same voltage level. This balance maximizes capacity,

Get Price

Why do lithium battery packs need to be managed in a balanced

Although the defect rate of lithium battery manufacturers may be very low, we still need to provide further quality assurance in order to guard against the problem of battery life being too short.

Get Price

GUIDE to properly Top-Balance and Charge a LFP

The ideal (and most time consuming) way to do initial top-balance for a battery will always be to take each Cell, subject it to standard charge

Get Price

How To Balance A Lithium Batteries: Top and Bottom Balancing

A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery pack.

Get Price

Li-ion Battery Pack Balance

When charging and discharging lithium-ion battery packs, we can take balanced measures to ensure safety and stability if we take into account the

Get Price

Techniques for Balancing Batteries-Improve Battery Life & Safety

Battery balancing might sound technical, but it''s a crucial process to ensure your batteries operate safely and last as long as possible.

Get Price

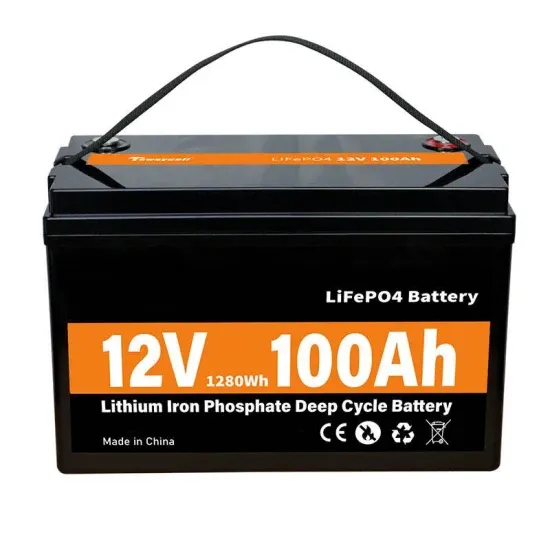

Do Lithium Batteries Need to Be Balanced?-Vatrer

A critical aspect of battery management is ensuring that all cells within a battery pack are balanced. This process, known as battery balancing, is essential for maintaining the

Get Price

lithium ion

0 Lithium ion batteries packs need to be balanced because of a small random voltage difference for each section in series, that may cause the voltage levels

Get Price

Techniques for Balancing Batteries-Improve Battery

Battery balancing might sound technical, but it''s a crucial process to ensure your batteries operate safely and last as long as possible.

Get Price

How to Balance Lithium Batteries with Parallel BMS?

How to Connect Lithium Batteries in Parallel Safely? In order to prevent potential hazards and optimize battery performance, it is necessary to

Get Price

Do LiFePO4 Batteries Need to be Balance Charged?

Do LiFePO4 Batteries Need to be Balance Charged? LiFePO4 batteries generally require minimal balancing due to their stable chemistry and built-in Battery Management

Get Price

What Is Lithium Battery Balancer?

This blog introduces what a lithium battery balancer is, its importance, how it works and how to connect it with the battery packs.

Get Price

Why Proper Cell Balancing is Necessary in Battery Packs

When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell voltages. This is not only for the

Get Price

Effective Cell Balancing in BMS: Maximizing Battery Health | NAZ

Explore the importance of cell balancing in BMS for lithium batteries, covering active and passive methods to enhance battery efficiency and safety.

Get Price

How to Balance Your Lithium Battery Pack During Installation

Proper lithium battery pack balancing before and during installation is essential for safety, longevity, and optimal performance. Following steps like parallel balancing, using a

Get Price

Do lithium ion cells needs to be equally charged before merging

Yes, they need to be of equal charge. It''s also important that they be matched both in terms of cell capacity and internal resistance. Typically, battery makers accomplish this by

Get Price

Can a Battery Pack Self-Balance? Exploring Cell Balancing in Lithium

Cell balancing is crucial for battery performance because it ensures that each cell in a battery pack operates at the same voltage level. This balance maximizes capacity,

Get Price

How do I protect 18650 lithium-ion cells in parallel?

If I want to power a cyberdeck with three 18650 lithium-ion cells in parallel (through an Adafruit Powerboost 1000C), what do I need to protect/balance the cells? The Powerboost is designed

Get Price

Battery Balancing: Techniques, Benefits, and How It

By balancing the cells, the battery system operates more efficiently, delivering optimal performance and extending the overall lifespan of the battery pack.

Get Price

Why Proper Cell Balancing is Necessary in Battery

When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell

Get Price

Battery Balancers: What They Do & Top Picks For 2025

Use Lithium or Lead-Acid Batteries – Compatible with various battery chemistries, including LiFePO4. Need Moderate Balancing Current –

Get Price

Do you need to balance Lifepo4 batteries in series?

1) battery not at same state of charge (not balanced) To your post title, it is important that batteries are balanced. Especially for series connected cells or battery packs.

Get Price

Charge Each Battery Individually for Greater

In-depth review on how to balance your Dakota Lithium LiFePO4 batteries including charging instructions and why they should be balanced.

Get Price

Battery Balancing: Techniques, Benefits, and How It Works

By balancing the cells, the battery system operates more efficiently, delivering optimal performance and extending the overall lifespan of the battery pack. Why Do We Need Battery

Get Price

The Significance of Cell Balancing in Lithium Packs

To sum it up, cell balancing is super essential for getting the most out of lithium-ion battery packs. By ensuring each cell has an equal charge, cell balancing boosts energy

Get Price

6 FAQs about [Do lithium battery packs need to be balanced ]

Does a lithium ion battery have a balance problem?

If you built a lithium-ion battery and its capacity is not what you expect, then you more than likely have a balance issue. While it's true that cells connected in parallel will find their own natural balance, the same is not true for cells wired in series. Battery cells in series have no way of transferring energy between one another.

Do you know how to balance a lithium battery pack?

Whether you are new to battery building or a seasoned professional, it's totally normal to not know how to balance a lithium battery pack. Most of the time when building a battery, as long as you use a decent BMS, it will balance the pack for you over time. The problem is, this can take a very, very long time.

Why is a lithium battery pack designed with multiple cells in series?

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell voltages. This is not only for the performance of the battery pack, but also for optimal life cycles.

Do all battery chemistries need balancing?

Not all battery chemistries require balancing, but balancing is essential for lithium-ion batteries and other multi-cell systems where consistent charge across cells is crucial for performance and safety. Q2: How Often Should I Perform Battery Balancing? The frequency depends on the battery type, usage, and the balancing system itself.

Why do we need battery balancing?

This process helps prevent overcharging or undercharging of cells, which can lead to performance degradation, reduced capacity, and shortened battery lifespan. By balancing the cells, the battery system operates more efficiently, delivering optimal performance and extending the overall lifespan of the battery pack.

What happens if battery cells are not balanced?

Battery cells in series have no way of transferring energy between one another. So if your cell groups are not perfectly balanced, the BMS will cut your battery off long before your battery pack is actually out of energy. What Is Lithium-Ion Cell Balancing? Cell balancing is the act of making sure all cells in a battery are at the same voltage.

More related information

-

How much does it cost to process lithium battery packs in Timor-Leste

How much does it cost to process lithium battery packs in Timor-Leste

-

How much does it cost to purchase lithium battery packs

How much does it cost to purchase lithium battery packs

-

Ghana supplies solar lithium battery packs

Ghana supplies solar lithium battery packs

-

What production equipment does the lithium battery station cabinet need

What production equipment does the lithium battery station cabinet need

-

Only lithium battery packs

Only lithium battery packs

-

Benefits of Libyan solar lithium battery packs

Benefits of Libyan solar lithium battery packs

-

Production of dual lithium battery packs

Production of dual lithium battery packs

-

Assembly of lithium battery packs

Assembly of lithium battery packs

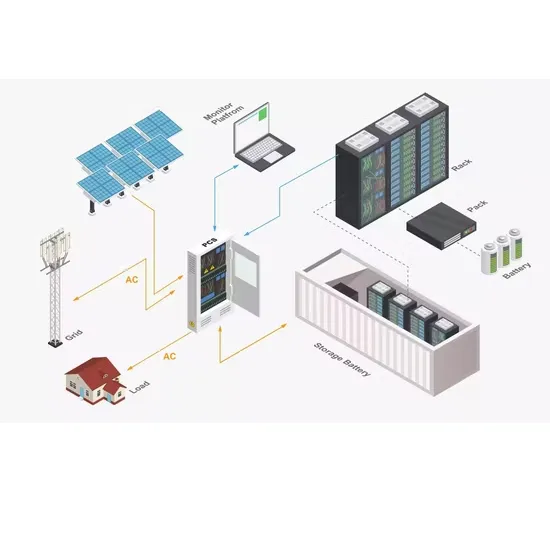

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.