Homeowner''s Guide to Going Solar | Department of

SETO resources can help you figure out what''s best for you when it comes to going solar. Consider these questions.

Get Price

Solar Panel Production Process: A Complete Guide

How are solar panels made? This document gives guidelines on the solar panel production process. It also gives details of the relevant raw materials that are

Get Price

New Legislation Tightening Domestic Manufacturing Requirements

For the Section 45X manufacturing credit, eligibility now requires battery modules to include "all essential equipment" produced domestically, with new stacking rules mandating at least 65%

Get Price

Production Meter Requirements for Solar Projects: SRECs & TRECs | YSG Solar

Below we have outlined the rule requirement and accuracy requirements for production meters for solar projects, specifically those projects eligible to

Get Price

Solar Calculator

Calculate how much power you need with these solar calculators to estimate the size and the cost of the solar panel array needed for your home energy usage.

Get Price

Requirements for a Solar Farm

A premier commercial solar company in California, Coldwell Solar boasts a large portfolio of projects in the commercial, agriculture, solar farm, and utility space as well as a variety of

Get Price

Solar Installation Regulations in SA You Should Know

Learn the solar installation regulations in SA with Alumo''s guide. We provide compliant installations that meet all standards. Let our experts guide

Get Price

New Legislation Tightening Domestic Manufacturing

For the Section 45X manufacturing credit, eligibility now requires battery modules to include "all essential equipment" produced domestically, with new stacking rules mandating at least 65%

Get Price

How to Start a Solar Panel Manufacturing Plant: Complete Guide

Solar Panel Manufacturing Plant Complete Guide: Discover everything you need to know about starting a solar panel manufacturing plant, from essential steps to industry trends.

Get Price

Wisconsin Solar Laws: Key Regulations and Homeowner Requirements

Understand Wisconsin''s solar laws, including installation requirements, utility policies, and homeowner rights to ensure a smooth transition to solar energy.

Get Price

Solar Panel Manufacturing Challenges & Opportunities

Solar energy is booming, and solar panel manufacturing is at the heart of this revolution. In this article, we''ll explore how solar panels are made and the biggest challenges

Get Price

Solar Panel Regulations in the United States: An

This guide explains how UL and ASTM standards, as well as FCC Part 15 and other requirements, apply to solar panels sold in the United

Get Price

Standards and Requirements for Solar Equipment,

d certification, equipment, and warranties for solar photovoltaic (PV) equipment and systems. It discusses a selection of programs and rules in these areas to highlight various means by

Get Price

What is required for solar panel production? | NenPower

To successfully manufacture solar panels, 1. raw materials must be sourced carefully, 2. production processes should be efficient, 3. regulatory standards must be adhered

Get Price

Solar Manufacturing

Aside from panels and their components and input materials (such as silicon metal and polysilicon or cadmium telluride powder), there are many different

Get Price

U.S. Solar Photovoltaic Manufacturing

The solar CS PV value chain comprises four primary stages of manufacturing, encompassing production of polysilicon, PV wafers, PV cells, and assembled panels. The majority of

Get Price

Solar Permit Guide: Requirements & Permitting Checklist

Switching to renewable energy is a top priority for many homeowners and organizations, but the shift to solar often requires major

Get Price

What Are the Safety Standards for Solar Panel Manufacturing?

Discover the essential safety standards behind solar panel manufacturing, from protecting workers against hazardous materials to ensuring environmental and electrical safety. Learn how strict

Get Price

What is required for solar panel production? | NenPower

To successfully manufacture solar panels, 1. raw materials must be sourced carefully, 2. production processes should be efficient, 3. regulatory

Get Price

Structural Requirements for Solar Panels — Exactus

This comprehensive guide outlines the structural requirements for solar panels and provides an overview on the inner workings of the installation

Get Price

Solar Panel Regulations in the United States: An Overview

This guide explains how UL and ASTM standards, as well as FCC Part 15 and other requirements, apply to solar panels sold in the United States. Note: This guide focuses

Get Price

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get Price

Solar Panel Production Process: A Complete Guide

How are solar panels made? This document gives guidelines on the solar panel production process. It also gives details of the relevant raw materials that are needed by solar panel

Get Price

Domestic content bonus credit

The domestic content bonus credit is an additional incentive credit available under the investment tax credit and production tax credit for businesses and other entities that invest

Get Price

How Many Solar Panels It May Take To Power Your Home (And

17 hours ago· Setting up your house to be entirely solar powered is an expensive exercise, and how many panels you need depends on your location and power requirements.

Get Price

Solar Manufacturing

Aside from panels and their components and input materials (such as silicon metal and polysilicon or cadmium telluride powder), there are many different manufactured products that are

Get Price

What Are the Safety Standards for Solar Panel Manufacturing?

Discover the essential safety standards behind solar panel manufacturing, from protecting workers against hazardous materials to ensuring environmental and electrical safety.

Get Price

6 FAQs about [Requirements for solar panel production]

What are the technical requirements for solar panel production?

Kindly take note of the following technical requirements during the solar panel production. The color and the size of the cells should be consistent. Be careful with the humidity levels. It should be less than 65% per day. The temperature range should be around 25 ±5. Of course, open the dehumidifiers when necessary.

What is a solar panel manufacturing plant Complete Guide?

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every aspect of setting up and operating a solar panel manufacturing plant, ensuring you have the knowledge and tools to succeed in this booming industry.

How do I start a solar panel manufacturing plant?

Establishing a solar panel manufacturing plant involves careful planning and execution. The first step is to create a comprehensive business plan that outlines your objectives, target market, and production capacity. This plan will serve as a roadmap for your operations and help secure financing. Next, selecting the right location is critical.

Why is regulatory compliance important for a solar panel manufacturing plant?

Navigating the regulatory landscape is crucial for the success of your solar panel manufacturing plant. Compliance with environmental regulations and industry standards is not just a legal requirement; it also enhances your brand reputation and customer trust.

How do I find suppliers for solar manufacturing materials?

Researching industry directories, attending trade shows, and networking with other manufacturers can help you find reliable suppliers for your solar manufacturing needs. What are the common challenges in solar panel manufacturing?

How long does it take to make solar panels?

The entire solar panel manufacturing process, from silicon wafer production to the final panel assembly, typically takes about 3-4 days. This includes cutting silicon wafers, assembling cells, encapsulating them, and quality testing before shipping.

More related information

-

Slovakia solar panel production plant

Slovakia solar panel production plant

-

Photovoltaic solar panel transmittance requirements

Photovoltaic solar panel transmittance requirements

-

Solar panel production in Northwest Thailand

Solar panel production in Northwest Thailand

-

Photovoltaic solar panel requirements

Photovoltaic solar panel requirements

-

Curtain wall solar panel thickness requirements

Curtain wall solar panel thickness requirements

-

Latest expansion of solar panel production

Latest expansion of solar panel production

-

Gas consumption in solar panel production

Gas consumption in solar panel production

-

New solar panel production plant

New solar panel production plant

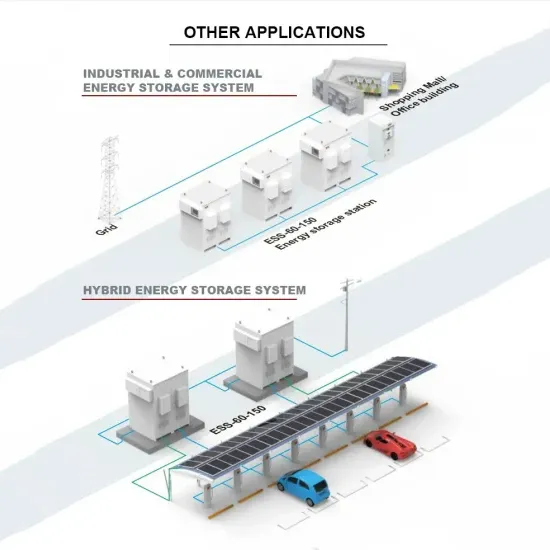

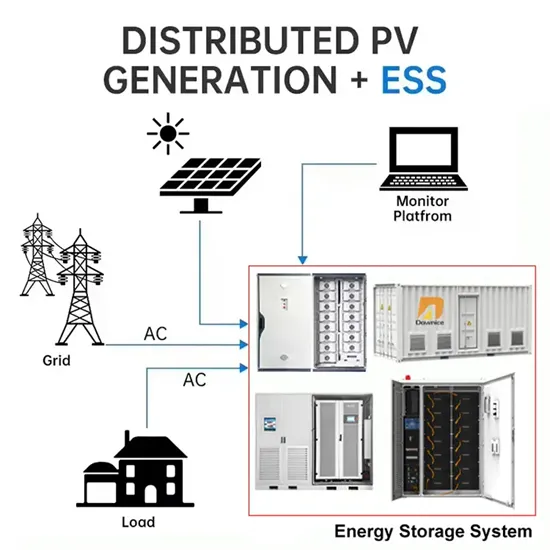

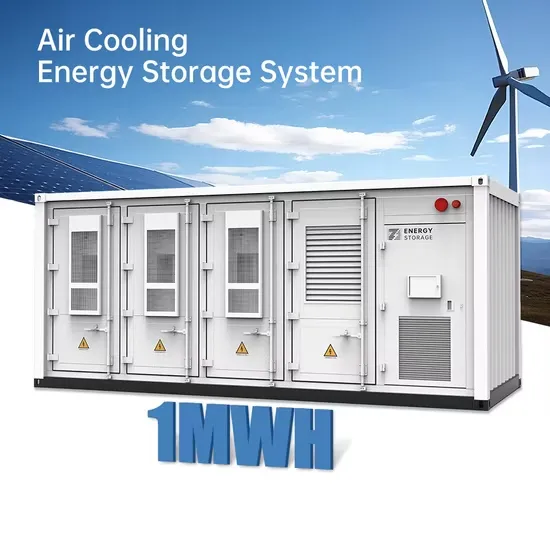

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with a 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with a 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.